10 Reasons Ethanol is the ‘Best’ Extraction Method

No doubt about it, ethanol extraction process is the best extraction solvent in the hemp industry… Or is it? In this article, we sit down with separations scientist and extraktLAB CEO, Jon Thompson, to discuss and debunk 10 common reasons that ethanol is claimed to be the best extraction solvent, and why they fall short to supercritical CO2 extraction.

Want to hear the full conversation? Watch Dr. Thompson discuss these top ten topics debunked.

10. CO2 Has Low Solvent Power

“The great thing about ethanol extraction process is it will dissolve everything.” says Dr. Thompson. “It’ll dissolve pesticides, undesirable plant materials, waxes, polyaromatic hydrocarbons, terpenes and any other millions of organic substances.” So ethanol does have the solvent power and it’s much stronger than CO2; however ethanol extraction process is not the perfect key for the cannabinoid lock.”

“CO2 has a particular selectivity and solvent power dependent upon temperature and pressure. CO2 has adequate solvent power at elevated pressures of 5000 psi at 50 degrees capable of extracting 90% of cannabinoids in about an hour. At low pressure and low temperature, CO2 can be used selectively to extract terpenes and terpene rich mixtures. You can’t do that with ethanol.”

“So, while CO2 has selectivity and ethanol has solvent power this one is plausible. CO2 absolutely does have lower solvent power compared to ethanol; however, when it comes to separations, selectivity trumps solvent power.”

9. CO2 Has Long Run Times

“This argument is predicated on the previous argument that, because CO2 has low solvent power, it also has longer run times, says Dr. Thompson. “Historically, CO2 has been run at low pressure, and in those conditions, it has been slow with average runtimes of four to six hours depending on your pressure and your temperature.”

“However, when pressure and temperatures are elevated, runtimes can be shortened significantly. Running decarbed biomass also increases overall runtime and allows processors to collect terpenes ahead of extraction so they’re not being degraded during the extraction process.”

“There’s no denying that ethanol is fast due to its solvent power. But, it is misleading to compare the solvent power for two solvents for a given solute without specifying the pressure, the temperature and the composition at which the comparisons are made. So number nine is busted.”

8. CO2 Extraction Has Low Throughput

“Again, this argument goes back to low solvent power and long run times, but we just don’t see this bore out in real life,” Dr. Thompson says. “Three extraktLAB E-180 machines can process up to one ton of biomass per day with a small footprint of 26 square feet per machine. I don’t think anybody in the hemp industry would say five tons a day in less than 4000 square feet is low throughput.”

“Throughput is important, but “throughput per what?” is the important question. For example, throughput per unit cost? Throughput per unit operating cost? Throughput per unit space? Or, throughput per unit facility cost? It’s very important to put throughput in context.”

“So, throughput is important but your “throughput per” is actually much more important. I put this as busted because we don’t have all the problems associated with ethanol and large amounts of solvent.”

7. CO2 At High Pressure Is Not Safe

“CO2 is gonna blow up, right?” Dr. Thompson asks. “This is what some of the ethanol and hydrocarbon extractors are saying which is ridiculous. I don’t know of any catastrophic event that’s happened with CO2 extraction equipment.”

“On the other hand, butane, propane, and ethanol have caused fires in this industry. You don’t have to go very far in the literature to see issues with butane and propane as well. There are safe ways to do all these techniques, so really we’re talking about the exception versus the rule. So, number 7 is busted.”

6. CO2 is Not Scalable

“This is absolutely not the case,” says Dr. Thompson. “Large scale CO2 extraction is a very common and well known industry that is safe in terms of scalability. What’s important is to make sure your facility is scalable.”

“You can start off at a low volume and then increase your production capability without having a tremendous upfront cost. As you increase your biomass, you’re increasing your output, you’re getting more profit, and can afford more equipment. The way we typically designed facilities is so that you can scale it up over time which is a great way to think about scalability, and CO2 is absolutely scalable. So, number 6 is busted.”

5. CO2 Equipment is Not Reliable

“In recent years, many manufacturers have upped their standard on reliability,” says Dr. Thompson. “Maybe four or five years ago, a lot of the manufacturers were using Haskell pumps, and they weren’t really designed for the conditions that they were applying them to. But today, a lot of the pumps are much more reliable including the diaphragm pumps that we use. We have been running 24 hours a day for many years on single pumps and have had no issues.”

“There are some people who start with single cylinders of CO2 in their operation and they’re always running out of CO2. So, that is one of the ideas that could make you think that CO2 is unreliable because you’re always running out of solvent.”

“To address this issue, we developed a product called the CO2Cage. The CO2Cage allows you to get a fill from a large bulk source, deliver it to your extractor, and keep it at the right pressure and temperature. So we’ve taken CO2 to the next level, and I think the whole industry has stepped up to the plate on that.”

4. CO2 Extraction Needs Ethanol

“This one is absolutely true,” says Dr. Thompson. “If you’re going to do CO2 extraction on a large scale, you’re probably going to be running some sort of winterization process. And, with an ethanol extraction process, they run winterization within the process.”

“Now, CO2 extraction does use a winterization process, but the ethanol usage is substantially less. So, you don’t need to worry about costs related to solvent loss or reuse, because you’re using so little food grade ethanol.”

“So, I have to say that this particular one is plausible. CO2 does need ethanol to make it work, but it’s a big ‘so what?’ because you use substantially less ethanol. It’s not even in the same category as ethanol extraction in terms of its ethanol usage. So, number 4 is busted.”

3. Solvent Residuals Are No Big Deal

“I totally disagree,” Dr. Thompson says. “We often see ethanol extraction process extract samples that pass solvent tests, but still have heptane, acetone, or other denaturants in them. There are no long term toxicity, or carcinogenicity studies on many of those class three solvents mentioned. They claim to be less toxic, but they only know that from the short term studies.”

“For example, people are adding heptane to ethanol to denature it. There’s a 5000 ppm limit on heptane but the FDA has claims that they don’t have the data for long term toxicity or carcinogenicity for heptane. That’s a problem.”

“Residual chemical solvents, and impurities are entirely avoidable using CO2 production methods. So, why take the risk with solvent residuals when a lot of it hasn’t been studied on cognitive function effects on endocrine disruption in the endocrine system? So, number 3 is busted.

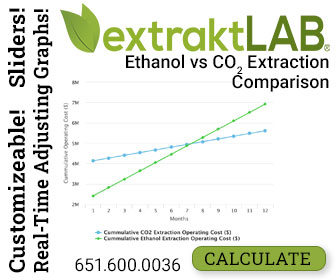

2. CO2 Equipment Cost Too Much

“You get what you pay for,” says Dr. Thompson. “CO2 equipment is definitely more expensive, it also has the lowest operating cost. Period. CO2 operations will generate cash faster, thereby paying the increased equipment cost and driving value for business for years.”

“If you look at the operating costs and not just the initial equipment costs, you’re going to come up to a very different conclusion. If you use our product the way we use it with CO2, the cost itself is extremely low. In that sense, our products are ridiculously inexpensive. Just do the numbers and you’ll know what I’m talking about. So I’d have to say that number 2 is busted.

1. CO2 Extraction Costs More Than Ethanol

“This is absolutely not true,” Dr. Thompson says. “CO2 uses four to six times less power than ethanol extraction process, because you don’t have to evaporate large amounts of ethanol. So CO2 wins.”

“Liquid CO2 is $.04 a pound, as compared to ethanol, which is $4.71 a pound, that’s 117 times less cost using CO2. This really drives a huge impact on cost if you have ethanol losses. Also, if you’re going to try to do organic extraction, you have got to buy organic ethanol, and that’s going to cost you even more.”

“Solvent loss cost per day for CO2 is about $211 for one ton a day, compared to ethanol, which costs anywhere from $4000 to $7800 a day, depending on the kind of ethanol used. Also, CO2 is a liquid startup that costs about $211, whereas the ethanol startup costs anywhere from $7,000 to $15,000.”

“So, CO2 extraction facilities are less costly and have low cost assurance compared to ethanol. Absolutely true. My advice to you is don’t mortgage your company’s future value by operating a high cost operation you need those profits to grow. So the number one argument is busted.”

Want to hear the entire conversation? Click the video below to hear these 10 reasons debunked in full detail and to see Dr. Thompson’s entire presentation.

Still wondering if CO2 is right for you? We’re here to help!

Whether you are new to the extraction business, or simply looking to optimize your business, we want to help. Sign up for a free, 20-minute Jam Session or call at: 651-600-0036 to discuss your current hemp extraction business and the solutions you want to see to take your business to a whole new level.

Contact Us To Get Started Today