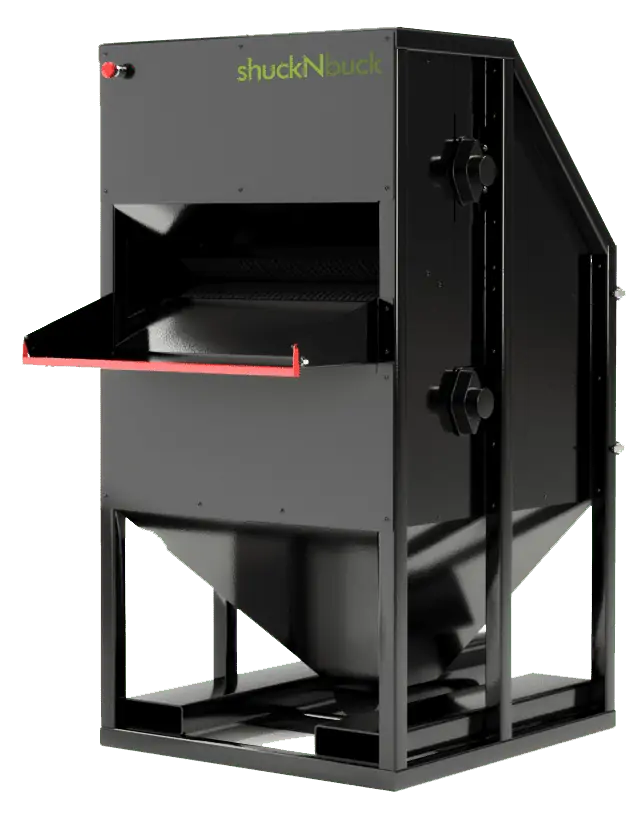

Bucking Machine

Process Your Harvest With The High Speed Bucking Machine Built For Volume.

shuckNbuck is a high-speed bucking machine for removal of hemp flower from stems and is designed for indoor or outdoor use. It delivers the capacity to process 1 acre of plant harvest in 3 hours, with a single operator. The biomass is deposited neatly into your container of choice for storage or shipment.

What is the shuckNbuck Bucking Machine?

The ShuckNBuck hemp bucking machine is by far the fastest dry-bucking machine on the market. Capable of processing over 1 acre of dry industrial hemp in about three hours, the bucking machine creates processor-ready ground material. The powder-coated carbon steel construction and 1 HP motors enable quick bucking with little to no effort.

The shuckNbuck hemp bucker comes with removable polypropylene food-grade brushes. The adjustable brushes are capable of producing ground hemp for further oil extraction. The unit works best at low moisture content of 15% moisture or less.

How Bucking Machine Works

The bucking machine is very easy to use when you follow the proper steps.

-

- First harvest the whole plant.

- Dry hemp to less than 13% water weight.

- Feed each hemp plant into the bucking machine while holding onto the stem.

- Pull stem out of the machine.

- Collect the bucked material.

What is a Hemp Bucker

Bucking of hemp is an important part of hemp processing. A bucking machine can help reduce the labor needed to remove the bud from the stems. This process is often called debudding or destemming.

Feature-Packed Hemp Bucking Machine Reduces Labor!

- Trailer Mount – The bucking machine can be trailer mounted and run from a generator for in-field hemp bucking.

- Cyclone – Convey bucked hemp material using the integrated cyclone. The material is neatly conveyed into bins or super sacks that are then used for shipping for further processing.

- Easy Loading – The bucking machine is designed for easy loading of the hemp material, easy removal of the destemmed hemp flower, and automatic separation of stems. There is no need for secondary conveyors to deal with the different stems and ground flowers.

- Easy Maintenance – Designed specifically for hemp processing, the brushes are food grade. The brushes are easily maintained by the operator and adjustable so that plants with different weights can be shucked, destemmed, or debudded.

- Extremely Fast – The shuckNbuck hemp bucker is equipped with a high power motor that enables high throughput bucking.

Advantages of shuckNbuck Bucking Machine

- 5 Second Processing Speed

- 2,000 plants in 3 hours (1 acre)

- Direct Fill of Super Sack Containers

- Indoor/Outdoor Use

- Lower Processing Cost

Bucking Machine Specifications

| ATTRIBUTE | VALUE |

| Machine Size | 70″ Tall x 42″ Wide x 56″ Deep |

| Machine Weight | Approx. 900 pounds |

| Frame Material | Powder-Coated Carbon Steel |

| Brush Material | Black Polypropylene |

| Operating Temperature | 0 to 95°F (50 to 70°F optimal) |

| Operating Humidity | 20 to 80% |

| Environment | Approved for indoor and outdoor use |

| Cleaning | Rated for washdown and forced drying |

| Output | 1.0 HP |

| Speed | 1,800 RPM |

| Voltage | 115V, single phase |

| Frequency | 60Hz |

| Current | 12.8 Amps |

| Bump Bar | Limit switch will disengage main contactor when 10+ lbs of force is applied to bump bar |

| E- stop | Switch disengages main contactor |

Learn More About Our Turnkey Manufacturing Solutions

Talk to our professionals about where you are and where you want to go. Doing it on your own can be overwhelming, but you are not alone. We are here to help.

Testimonials

You have common sense in your explanations and conversations.

Timely, direct, knowledgeable.

The whole team made our purchasing experience a pleasurable one.

Very thorough. Extremely knowledgeable staff. Great teachers!!

Frequently Asked Questions

Why is grind size important for efficient extraction?

Grind size is an important consideration when conducting either CO2 extraction or ethanol extraction. Grind size may be important for different reasons however, depending on the extraction method. Here are some key details for that are important for grind size:

- The grind size is small with CO2 extraction so that more materials can be packed into the column. A small particle size wheel packs more efficiently into the column and thereby prevents channeling within the column.

- Improved mass transfer is the second reason a small grind size is desirable.The larger the particle size, the longer the cannabinoid will take to diffuse out of the particle and into the flowing stream.The smaller the particle size the better the Mass transfer will be and the shorter the time the cannabinoid will take to diffuse out of the particle.. This is true for both ethanol and CO2 extraction. One important aspect of grind size is particle size distribution. Four particles of all the same size, extraction is more uniform. or a mixture of very small particles and large particles, a small particle will be extracted before the large particles. those small particles then begin and start you over extract.

What kind of safety stops are featured on the shuckNbuck?

There are three safety stops. There is a bump bar on the front below the loading zone, the e-stop button on the front top above the loading zone, and a kill switch is activated when the back door is opened. Please consult the manual for additional safety features and warnings.

How can I clean the shuckNbuck between lots?

The shuckNbuck is rated for washdown and forced drying so you can hose it down between uses.

What is included in the standard price?

Instruction Manual is included. Certs documentation available as an option.

How many people does it take to operate the shuckNbuck?

You can safely operate the shuckNbuck with just one person.

When operating how loud is the shuckNbuck?

When the shuckNbuck is turned on, it is about as loud as your electric dryer. Check the manual for recommended ear protections.

What about dust control?

You can connect the shuckNbuck to your own dust collection system using off-the-shelf adapters, or you can purchase an additional dust collection solution directly from us.

About how long does it take the shuckNbuck to process an acre of harvest?

One operator can process an entire acre of plants in just 3 hours.

Meet Our CEO and Founder Dr. Jon Thompson, Ph.D

Dr. Thompson is the founder and CEO of extraktLAB, where he has devoted his time to helping various hemp manufacturing companies in achieving their business goals. His expertise also extends to market development, strategic marketing, and business-to-business alliance formation across the globe.

His extensive knowledge of the hemp extraction industry has earned him recognition in winning and implementing medical licenses in well-regulated, medically-modeled states.

More than that, Dr. Thompson is also a separations scientist with a strong background and deep industry experience in analytical instrumentation, in-vitro diagnostics, biotechnology, mining and homeland security markets.