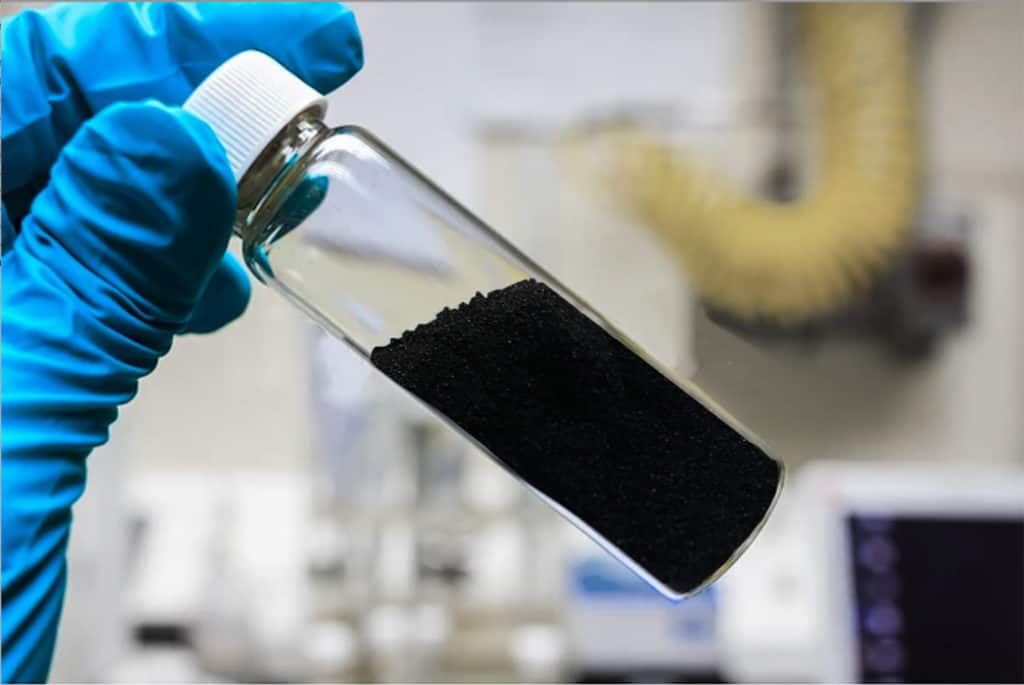

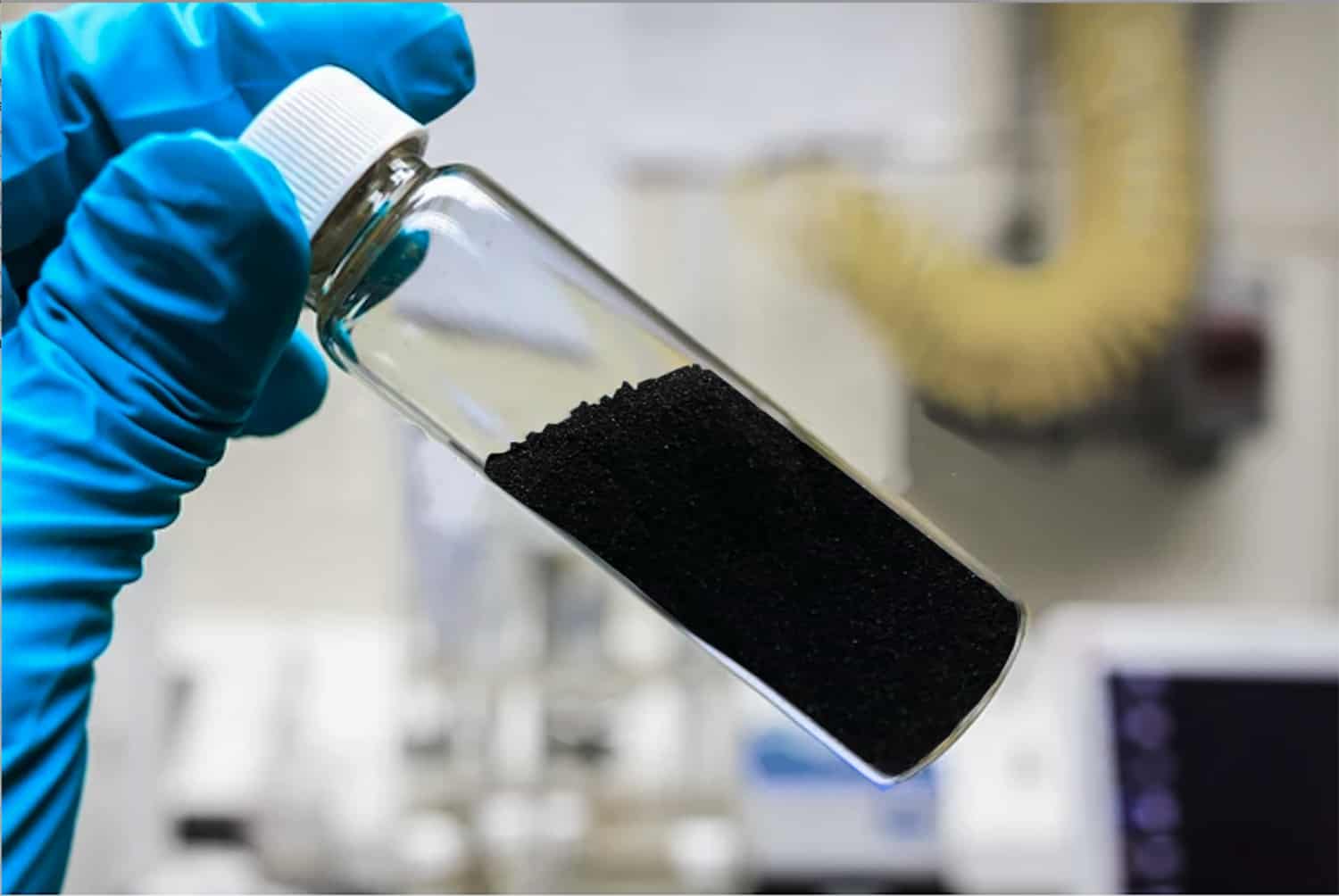

carbonX

carbonX is a mechanically stable color remediation media that can be coupled with the DrainDroyd to remove plant chlorophylls and other plant materials causing dark, undesirable color in your extracts.

carbonX is radically different from activated carbon because it does not break up or discolor your hands with handling, and combustion byproducts will not dissolve into your extracts after the extraction process.

carbonX FEATURES & BENEFITS

- 10 Times Lighter Oil

- Does Not Break Up Or Crumble with Handling

- Does Not Make Your Hands Black with Handling

- Combustion Byproducts Will Not Dissolve Into Your Extracts

- Material Can Be Used In A Filter Funnel Or Dispersion

ENGINEERED FOR ANALYSIS:

Stable pore structure; Consistent pore structure; Stable particle size; Selectively adsorbs analytes

PROVIDES:

Better flow; Better remediation; Better throughput; Better reproducibility

BENEFITS:

Does not ned toluene; Reduced GC Maintenance, with 4x less liner usage; Unique selectivity for polars; Great pigment, lipid remediation; Tri-phase carbonX SPE without any reduced flow

carbonX will provide the clarity needed in your hemp or cannabis extracts.

Activated carbon or charcoal is a very popular method of chlorophyll removal and color remediation, but tends to have its own drawbacks.

extraktLAB’s answer to these oil refinement issues is carbonX, a color remediation solution with a faster filter rate, higher pressure threshold, and consistent particle size.

Decolorization Methods Using carbonX

carbonX is an incredibly useful tool for remediation of dark color form your hemp or cannabis extract. There are a few methods you can use in your process to remove plant chlorophylls to ensure a more desirable extract color and quality with carbonX:

Dispersive Method

- Sample product dissolved in ethanol by placing 2mL into a clear test tube

- Place 1g carbonX per 100mL into a glass bottle. Shake bottle and let sit for 5 min.

- Sample ethanol again by placing 2mL into a clear test tube. Compare to the original sample.

- If a lighter color is desired, increase the amount of carbonX to a total of 4g per 100mL.

- Shake for 1 minute on a commercial bottle shaker or roller.

- Let the solution sit for 5 minutes.

- Retest using step #3.

- Repeat by increasing carbonX until desired color is achieved. It is critical there is sufficient time for adsorption between increased levels of carbon.

- Filter the carbonX using a new technical paper and the Buchner funnel apparatus. Recover carbonX from filter paper. Regenerate carbonX according to procedure below.

Filter Bed Method

- Sample ethanol by placing 2mL into a clear test tube.

- Place technical paper in a filter flask.

- Place 600mL of carbonX into a glass filter flask.

- Place glass filter flask on 4L sidearm Erlenmeyer.

- Wet technical paper with food grade ethanol.

- Turn on the vacuum.

- Pour dark ethanol solution through the filter cake.

- Collect filtrate in 4L flask.

- Sample ethanol again by placing 2mL into a clear test tube.

- Compare to the original.

- If a lighter color is desired, repeat the filtration.

Regeneration procedures

carbonX will eventually foul and become unusable. Here are three methods to regenerate carbonX.

Ethanol & Water

You can wash carbonX with hot food grade ethanol to remove waxes and fats, and then boiling water to remove chlorophyll.

To do this you should use the filter bed method described above, or on a larger scale, the table top Buchner. You can rotovap the ethanol and discard the residue. Boiling water should be discarded.

Supercritical CO2

You can regenerate the carbonX with supercritical CO2. You will need a filter bag and a supercritical fluid vessel and CO2 source. Temperature is 80ºC at 5000 psi. Waxes and solids will elute from the carbon. Recommended time is 2 hours at 100mL/min.

Butane

You can regenerate the carbonX with butane. You will need a sanitary pool and filtration bags.

related equipment