High performance liquid chromatography is an essential function in any hemp extraction businesses. There are a number of HPLC applications within the extraction market capable of streamlining and upscaling any cannabinoid product line. In this article we discuss chromatography uses, applications and the pure99 system.

With the world of hemp extracts evolving every day, there are now product formulations that are both desired, and mandated on the market. Research shows that different cannabinoids result in different potential effects and customers are quickly learning what works best for them. With that, national regulations are strict in the allowance of THC levels in hemp products. For these reasons, HPLC applications have become essential in any hemp extraction business, and pure99 has refined that process to the highest quality to date.

What is HPLC Chromatography?

Very simply, chromatography is a technology used to separate the various compounds of a solution. In the hemp industry, it allows producers to separate a list of compounds in the hemp plant to allow for a specifically formulated product that is both legal and tailored to the market demands. It is also capable of identifying and removing unwanted pesticides, and other residual chemicals. Let’s get into the details of HPLC applications and pure99 with R&D Chemical Engineer, Aaron Iwen.

The list of chromatography uses in separations science is long and detailed, but there is yet to come an HPLC system tailor made to the hemp industry as pure99. When extrakLAB designed pure99, this was the goal they had in mind. This way, the expanding world of full spectrum and THC-free products can be properly formulated without fear of meeting FDA Regulations or creating a product that is not specific to customer desires. “What pure99 is all about is maintaining a full spectrum profile in the end product,” Iwen says. “You can maintain your CBD, CBG, CBN, CBL and so on, but keeping all of that while selectively removing THC cannot be done with your typical isolation production process. You need a very particular target removal and that’s where pure99 comes in.”

What is pure99?

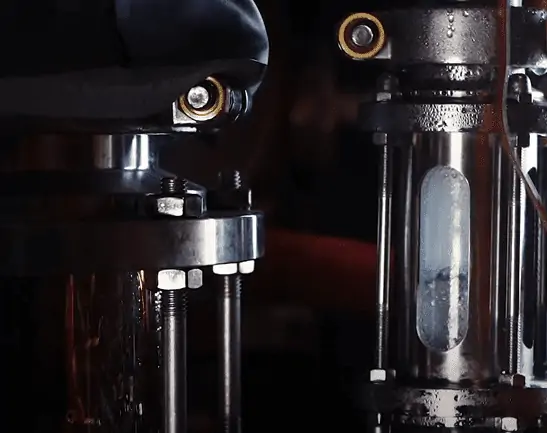

So, pure99 is HPLC chromatography for the hemp producer, but what exactly does that mean? What benefits would a manufacturer have by using this in their own extraction business? “pure99 is a scaled chromatography system designed to separate cannabinoids of particular interests,” Iwen says. “It’s a liquid chromatography system. What’s great about this is that a manufacturer would be able to use a combination of solvents in order to achieve a target separation. One of the things that is unique about a liquid system is that you have a certain amount of liquid consumption.”

No scalable solution… until now.

“One of the things that makes chromatography not necessarily scalable is the amount of liquid that you consume. The issue of scalability goes hand-in-hand with liquid solvent recovery.” “That’s why there are no real scalable HPLC applications on the market right now. What has been cool about our ability to recover the liquid is that the fracTron has been integrated into our pure99 design to reclaim a lot of your liquid consumption and recycle it back into the start of your process.”

FDA regulations make pure99 essential

The hemp and CBD industry has a strict set of regulations according to the jurisdiction of any particular country. For example, The United States’ FDA regulations on CBD products requires that a product contain no more than 0.3% w/w THC. The problem with this is that hemp cultivators may have issues growing a crop that truly contains less than 0.3% of THC. Thus, if a CBD product is made from biomass that contains more THC than is federally approved, it cannot be sold as it would be a technically illegal product. So, what then? The answer lies in chromatography.

Particular HPLC Applications: Pesticides, Chemicals, Cannabinoids and Terpenes.

“There are an infinite number of variables in biology that could affect your plant, so you’re not going to be able to get around regulations just by the selection of a plant. There are people that want full spectrum products where the cannabinoid profile is unedited.” “That’s great if you have the plant that can give you that, but it has to maintain the legal regulation; the bottom line is that many plants don’t have that. You can’t even predict it. You can make every effort to have minimal THC in your biomass, but different variables are going to cause different products to be created. That could mean more THC even in a strain that you specifically selected to have zero THC.” “And, while most of this technology is geared towards cannabinoid separation and removal, you could potentially remove unwanted pesticides from a final product if it is tuned to a specific target.”

The Reality: Chromatography Will Always be Necessary

Even if the FDA removes the less than 0.3% THC regulation, there will still be customers on the ground floor and producers that will desire a product that is thc free. This means that chromatography will always be an essential part of the hemp product formulation process. Chromatography uses will always be necessary. Not only is it legally necessary while certain regulations on THC are in place, there will also always be customers that are looking for a CBD product that has zero THC. You’re never going to be able to get around it.

Get the Best in Chromatography for Your Business

You need to incorporate HPLC chromatography into your production to ensure the healthiest and up-to-code products. Why not use the smallest footprint, most efficient supercritical fluid chromatography system? Give us a call at 651-600-0036 to consult one of our specialists and get a quote today!