CO2 Supply

CO2 Cage & MPCart Solution

Supercritical CO2 extractor machines require a reliable source of CO2 supply at constant pressure levels for efficient extraction. extraktLAB has created CO2 supply solutions for any manufacturing capacity or production configuration.

Micro Bulk CO2 Tank

Access Our CO2 Supply Product and System

Get started with our microbulk tank CO2 supply management systems and find out which solution fits best for your business.

Advantages of CO2 Supply Management Solutions & Applications

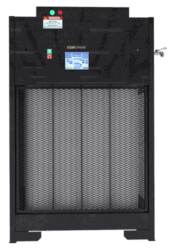

The CO2Cage is a CO2 cryo tank supply vessel that holds your business’s bulk gas or liquefied gas via 16 integrated and manifolded 100 lb DOT-approved gas or liquid CO2 tanks. This microbulk tank is typically used in applications where the installation of refrigerated bulk storage tanks is not feasible or available. There are many CO2 applications and unlike other cryogenic storage tank options, the CO2Cage solution has a range of benefits including:

- Built-in CO2 monitoring and ventilation

- Consistent delivery of gas

- Eliminate gas outages

- Eliminate CO2 gas waste and cumbersome gas cylinders

- High pressure system can deliver up to 1200 psi liquid or gas.

- Gas or liquid can then be efficiently pumped to each point of use.

- Automated filling using a liquid CO2 pump from a large CO2 tank

Learn More About Our CO2 Supply Management System

Get the latest specifications and compare our microbulk tank CO2 supply management systems to find out which solution fits best for your business.

Frequently Asked Questions

What are the alternatives to using a microbulk system?

Gas cylinders may be used in lieu of a micro bulk system. If liquid CO2 is required, then the cylinders must be installed with a siphon tube. The cylinders should be clearly marked as having a siphon tube or be color coded as such. You can tell if the Co2 tank has a dip tube by the dark color of the collar on top of the tank.o2

What method do I use to fill the CO2 system?

AIGA method 069 filling method is used to fill the microbulk system.

Can I store the microbulk CO2 system Outdoors?

The microbulk system is only rated for indoor use.

What are the certifications for the control panel and the cryogenic tanks and the gas cylinders?

The gas cylinders are DOT and approved and available to be shipped to Canada and the United States. The electrical control panel is UL listed and is compliant with UL508a.

How many pounds of CO2 can I store in the microbulk system?

The system is capable of storing okay 1600 lbs of liquid CO2.

What electrical installation is required for the microbulk system?

The system requires 24 full load amps at 208 volts, 3 phase, 60 hertz. A earth ground is required for installation.

Can I use the micro bulk CO2 tank as a source for dry ice?

Yes.The microbulk tank is an excellent source for dry ice and liquid CO2. It can be used for many different applications including CO2 blasting, CO2 extraction, and also in brewing & beverage processes.

When using the microphone look CO2 tank as a source for dry eyes, it is important that the user is trained and is properly grounded.

What is the difference between a micro bulk CO2 tank and a bulk CO2 tank?

A CO2 bulk tank typically feeds a microbulk Co2 tank. Bulk CO2 tanks can range from 3 to 50 tons. Both tanks are typically also cryogenic tanks that are designed to keep the cryogenic fluid cold so that it does not vent off and waste the cryogenic liquid. In contrast, a micro bulk CO2 tank will typically range from a half a ton to a ton and are typically not refrigerated. Micro bulk tanks are typically filled periodically by beverage CO2 Supply trucks or they can be installed in a CO2 system that is supplied from a bulk tank.

How does the microbulk system maintain the temperature and pressure of CO2 delivered?

Our systems have incorporated a proprietary heating element that enables a very consistent pressure and temperature of the CO2. The pressure of CO2 coming off a bulk CO2 tank is around 300 PSI. This is due to the fact that both tanks are typically refrigerated and they are kept at that temperature so that they remain as a liquid. As the liquid heats up, the pressure will also increase. Room temperature CO2 is typically 800 to 900 PSI.

What are the requirements for the installation of CO2 supply in a room?

The Compressed Gas Association of America has promulgated rules for the installation of CO2 systems in indoor facilities. They suggest that a minimum of 1 CFM per square foot exhaust venting is required for venting in the event of a leak. Second they require a CO2 monitoring system that will alert users to a leak or potentially harmful condition.

If there is a leak is the CO2 tank vented?

In the event of a CO2 leak, the built in CO2 monitoring system alerts the user to a lie condition. The monitor then directs a fan to vent the micro bulk tank so that no CO2 can escape into the outside room. This enables a high degree of safety for your employees.

How to fill the CO2 microbulk cage?

The CO2 micro bulk tank is filled with a CO2 pump. The CO2 pump pumps liquid CO2 from a supply truck or a bulk tank to the micro bulk system. The CO2 pump connects directly to the CO2 microbulk tank and is automatically controlled from the control panel on the front of the microbulk system.

How much CO2 do I need to use per month for a microbulk system to make sense?

If you use more than 10 gas cylinders of CO2 per month, a microbulk cryogenic tank system might be very advantageous for you. System can be filled from a beverage Co2 supply truck. An email can be sent to the supplier to alert them when you have either high usage or are running out of CO2.

Meet Our CEO and Founder Dr. Jon Thompson, Ph.D

Dr. Thompson is a separations scientist, entrepreneur, and inventor. As a scientist, he has a strong technical background and industry experience in analytical instrumentation, in-vitro diagnostics, biotech, mining, and homeland security markets. During his extraction industry career, Dr. Thompson has earned a strong track record of setting up successful startups in well-regulated industries. Dr. Thompson has assisted numerous companies to attain their goals in essential oils manufacturing, as well as market development, strategic marketing, and worldwide business-to-business alliance formation (including international markets).

He received a Bachelor of Science degree in Biochemistry, Master of Science degree in Chemistry and a Doctor of Chemistry degree–all from the University of Minnesota.