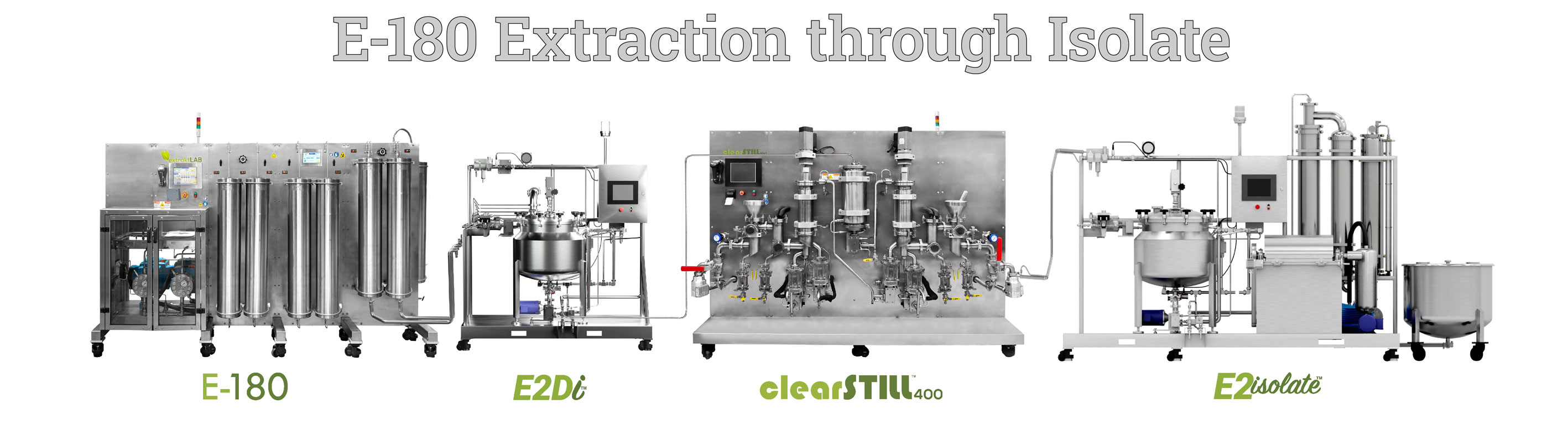

Supercritical CO2 Extraction Machines

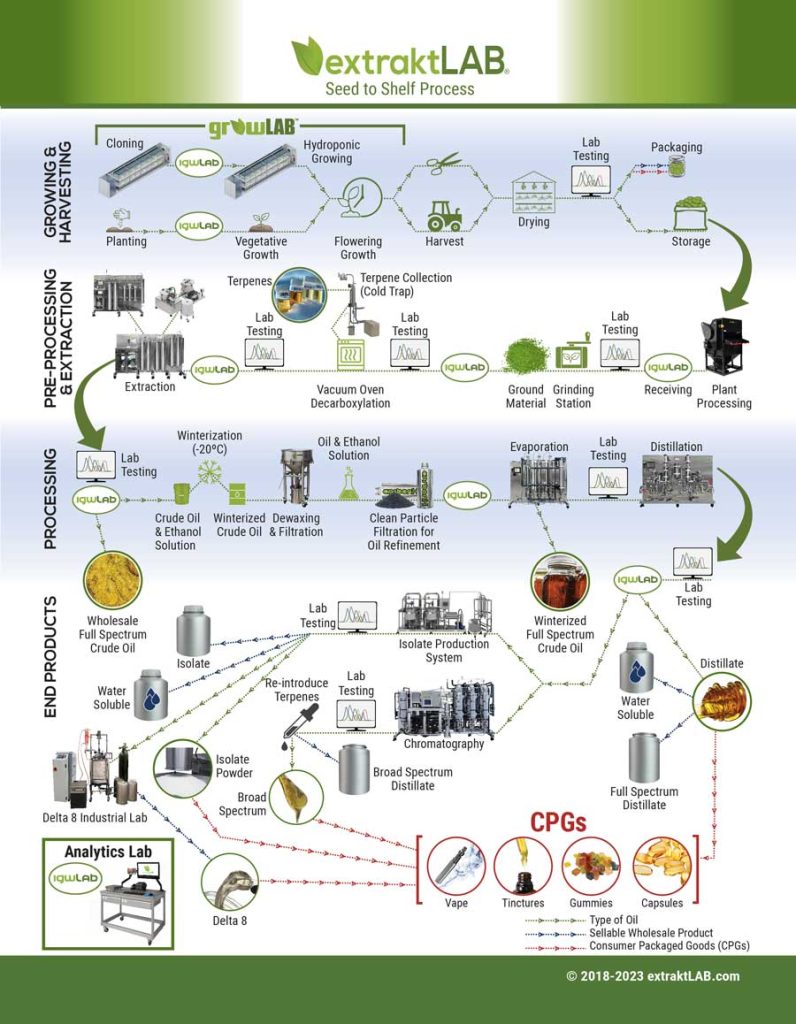

From seed to shelf, extraktLAB has turkey botanical extraction manufacturing equipment solutions, services, and software.

Extraction Equipment

Botanical extraction equipment needs vary by methods used. extraktLAB offers equipment to provide record speeds using the safest and purest methods to achieve high-quality oils. Supercritical CO2 extraction equipment costs more upfront but has lower long-term operations cost.

supercritical co2 extraction

Supercritical CO2 extraction offers lower infrastructure and operation costs with higher yields and almost no possibility for contamination by chemical denaturants.

The E-140 and E-180 are capable of being scaled up to 5000+ lbs/day and incorporated into the various automation solutions.

Scalable, Fully Automated

Suitable for Small Scale or REsearch & Development Operations

Ethanol extraction

Ethanol extraction offers lower upfront costs, and when food grade ethanol is used and handled properly it can be a safe and efficient extraction method.

Ethanol extracted extracts must be distilled to removed all residual solvent.

Seed to Sale Software & Hardware Station

igwLAB is a tracking software integrates and manages your manufacturing systems. This manufacturing execution system (MES) helps decision makers understand current plant floor conditions and how to optimize for production output improvement.

manufacturing execution system

Create, store, and report your batch records in an industry specific cloud software platform with secure Wi-Fi connectivity for GMP compliance of documentation & data. Includes individual and collective tracking in 13 modules for maximum traceability.

CO2 Supply Equipment

The CO2 Cage is a microbulk storage solution, when paired with the eMPCART your CO2 Cage can be more than 100 feet from the bulk tank.

safe & convenient c02 storage

The CO2 Cage integrates 1600 pounds of liquid CO2 with automated fluid conditioning & monitoring. Contact closure and enclosed system for automated venting and on board CO2 gas monitoring for leaks.

The eMPCART integrates with the CO2 Cage to automatically signal filling at a fill rate of 20 pounds/min and 4-20mAmp connectivity to the CO2 Cage.

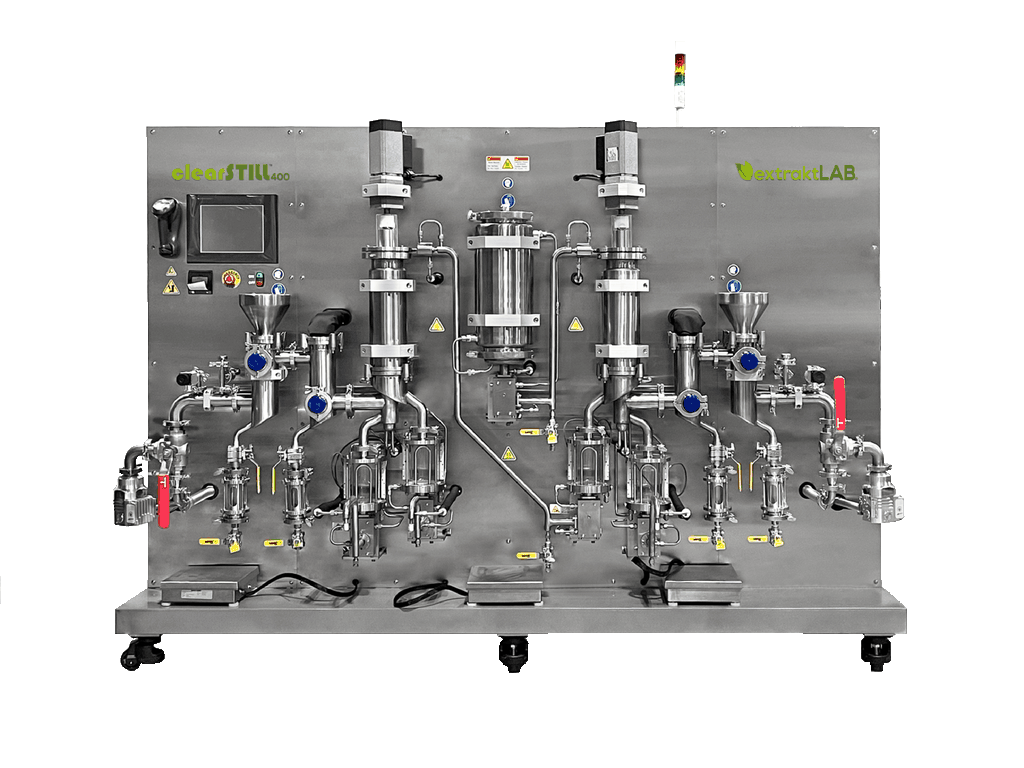

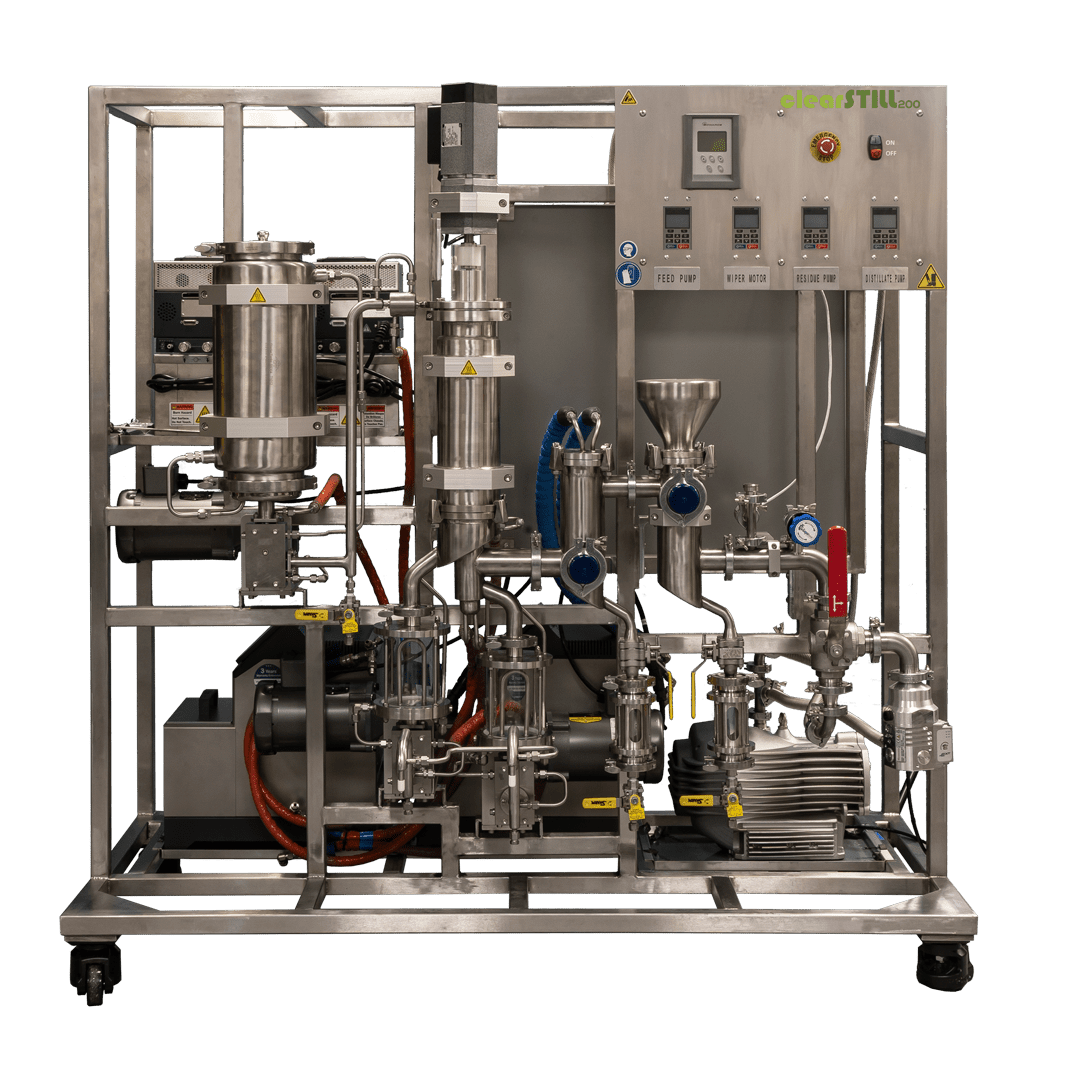

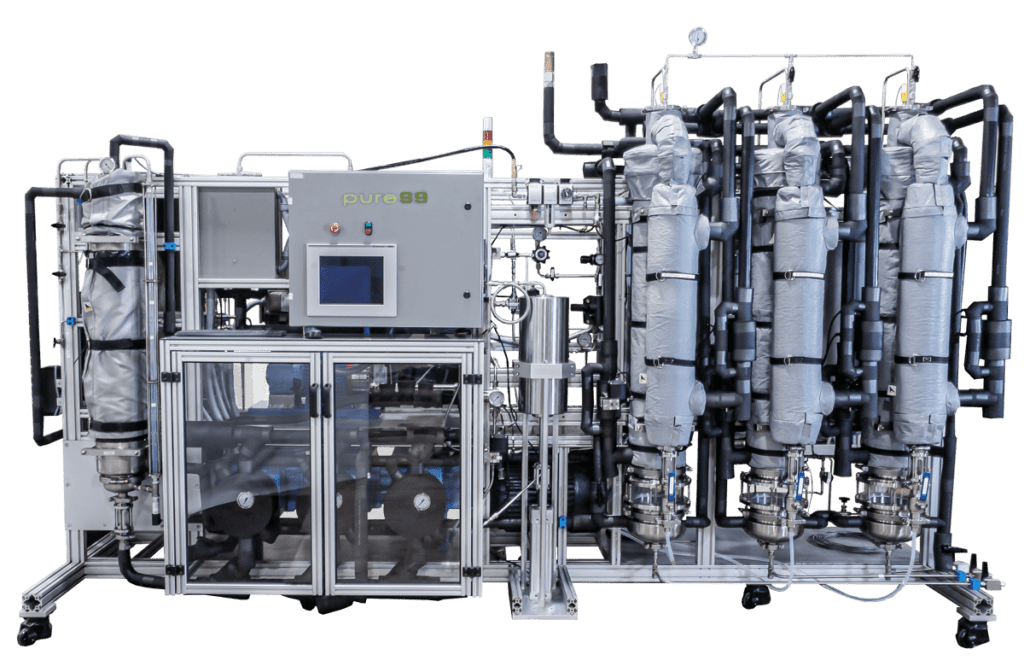

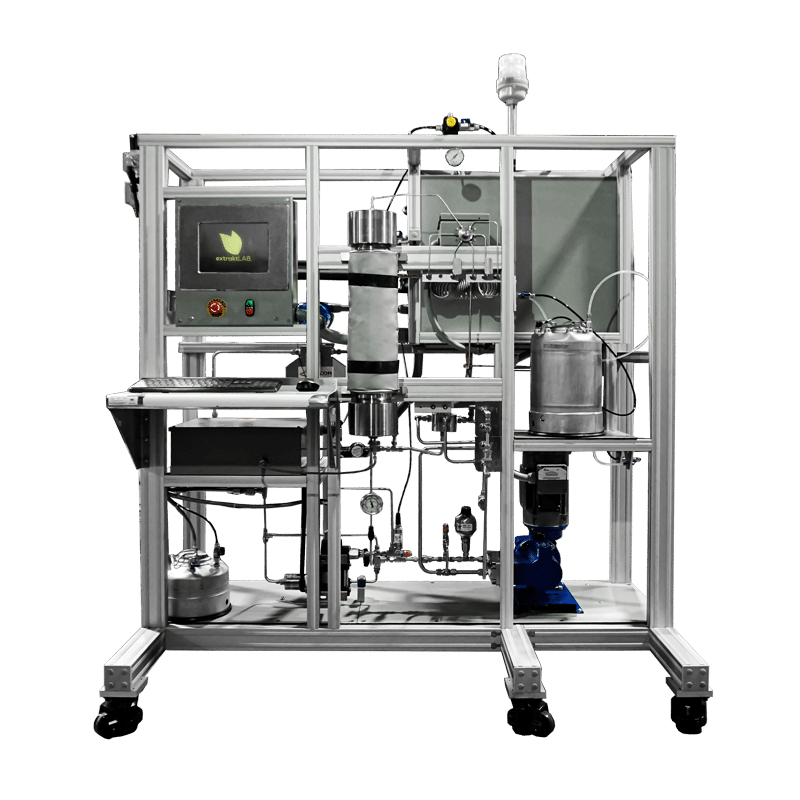

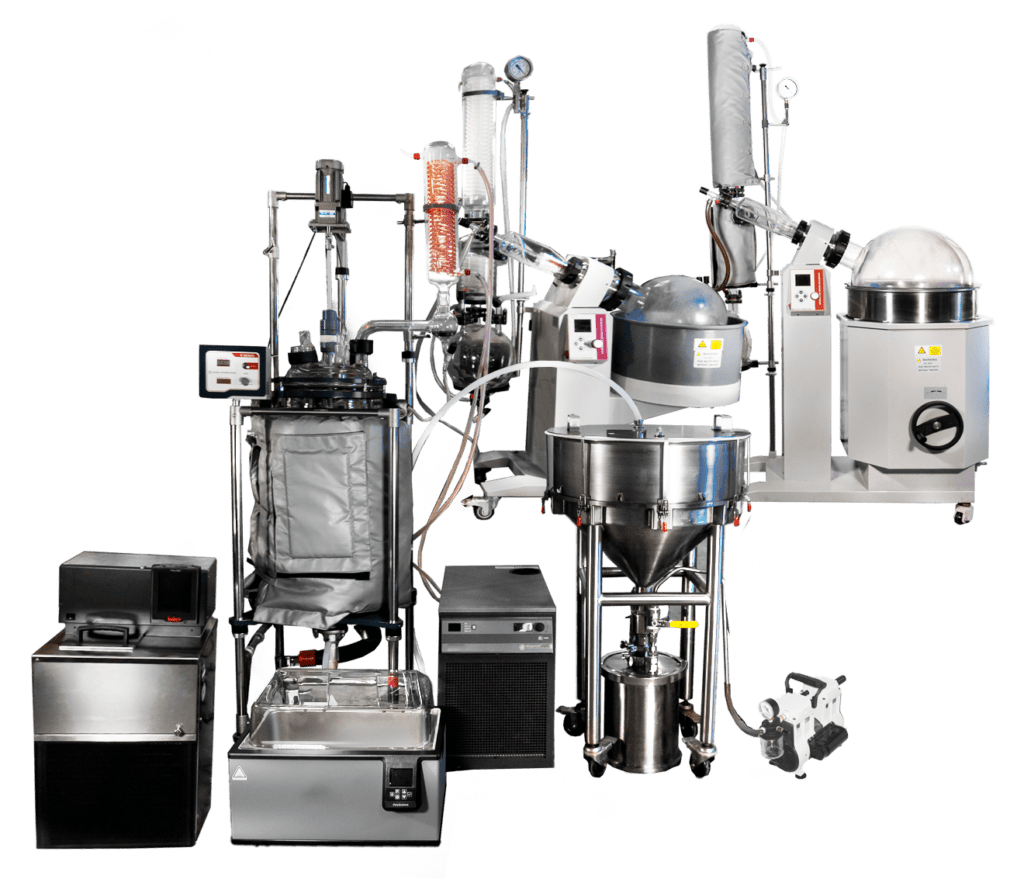

Distillation Equipment

extraktLAB offers falling film fractional separation and wiped film distillation equipment capable of being incorporated into automation processes and methods. There is also equipment designed for the small scale producer or research and development team.

Three Stage Fractional Separation

Up to 40 gallons/hour capacity with inert carrier gas and independently controlled stills. Continuous flow reduces labor and complete solvent removal eliminates secondary processing.

Continuous two stage Distillation

Throughput capacity of up to 4-6L/hour, providing half the labor and double the volume of single stage systems. Automations and reduced labor and cleaning downtime. Continuously feeds from fracTron-1000.

Single Stage Batch FalLing Film

Capacity of up to 20 gallons/hour with an air-driven pump. C1D2 compliant

Single Stage Wiped Film Distillation

Throughput capacity of up to 2-3L/hour with high temperature maintenance.

Chromatography Equipment

Whether you’re starting working in research and development or have a full-blown facility, we have a closed loop solvent recycling high-pressure liquid chromatography machine for you.

complex compound separation

High pressure injection with up to 7 L/min flow rate and user packable, large diameter columns. Built-in solvent recovery falling film distillation. Additional upgrade columns available.

high degree of versatility

Sample loop up to 100 mL with automated batch operation. High pressure mixing eliminates need for solvent degassing & helium sparging. Additional upgrade columns available.

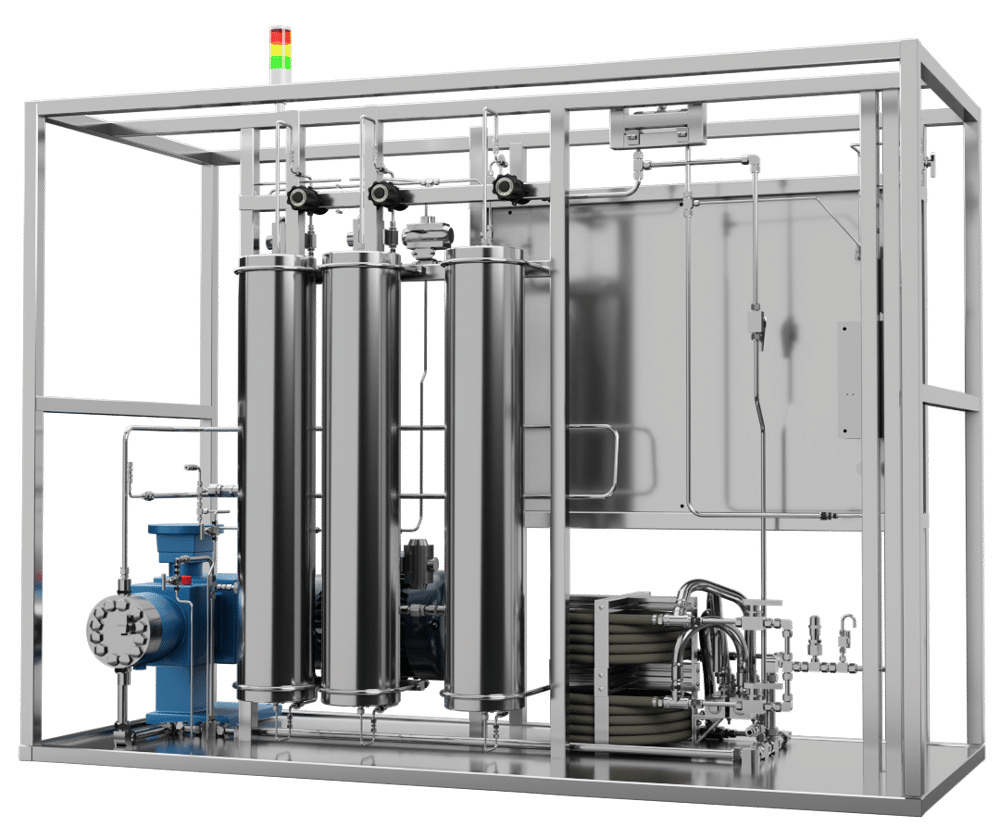

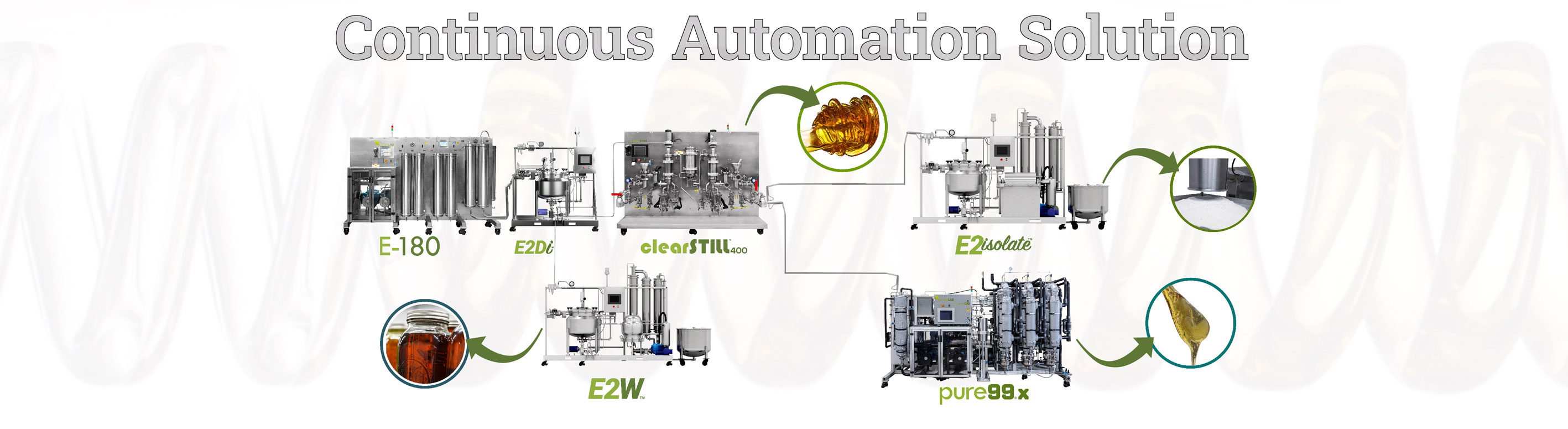

Automation Process Solutions

A continuous automation solution will revolutionize your extraction process with the latest in automation technology. When you automate your process you unlock your potential, integrate automation into your manufacturing process and you will profit from less variation, less human error, and less contamination. Each automation system offers sustainability; reduced infrastructure requirements, downtime and labor costs; and higher recovery.

Turnkey Solution Ancillary Equipment

extraktLAB has customizable equipment for each step of your manufacturing process. Having integrated equipment will save you time and effort, while increasing profitability.

Harvesting | High Speed Bucking

Indoor/outdoor high speed bucking machine for the removal of hemp flower from stems with a throughput of 5 seconds/plant. You can process up to 2000 plants (1 acre) in three hours.

High speed Filtration

GMP compliant stainless steel construction with multiple accessories to expand methods. Fastest filtration method in the industry, easily integrates into existing processes and no glass or spillage. Choice of jacketed filter top or condenser top.

terpene collection | Decarboxylation

The most versatile terpeend and vapor recovery cold trap terpene collector. Don’t throw money away – collect the terpenes! Full spectrum terpene recovery with GMP compliant product contact surfaces.

Color Remediation

Mechanically stable, doesn’t break up or discolor your hands with handling. Keep extracts pure without dissolved combustion byproducts.

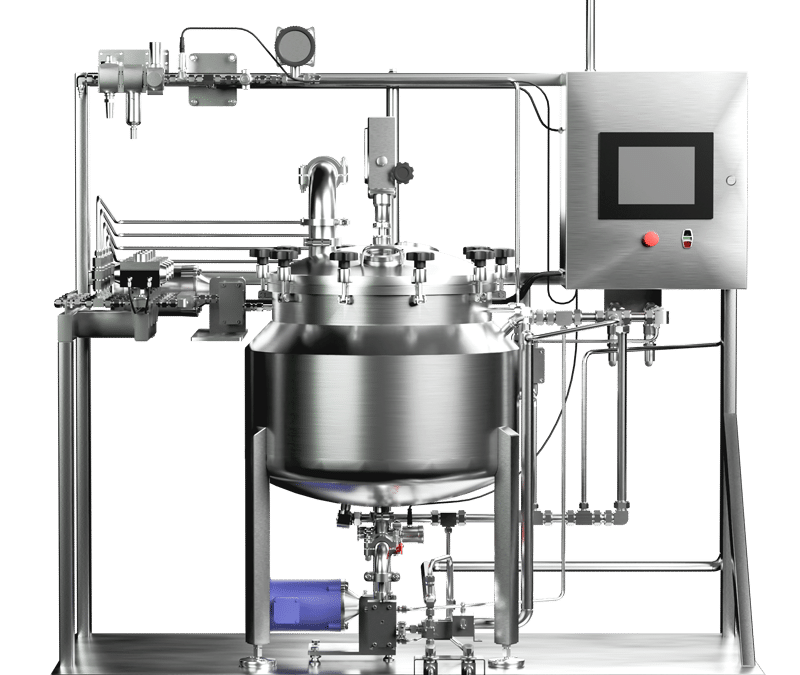

Crystallization Labs

No more outsourcing these common productions – you can now incorporate these into your facility without the guesswork.

Bulk Delta-8 THC

Take control of your Delta-8 production process and meet production uptime and deadlines.

Bulk Isolate Production

Produce your isolate with proven equipment, methods, and the needed education to start probably.