Making CBD isolate powder is a critical aspect of any hemp processing business. Because of its potency and versatility, CBD isolate powder is a key product for any producer’s product lineup. This article will detail the process of making CBD isolate powder from start to finish and explore some of the complicated processes to make quality CBD isolate powder.

How to Separate Cannabinoids from CBD

CBD isolation is a key process in hemp remediation. There are many different techniques and alternatives to separations. Separating other cannabinoids from CBD using different types of chromatography, liquid-liquid extraction, and degradation have been widely investigated. Chromatography has experienced widespread adoption as the leading CBD isolation method.

CBD Isolation from Hemp

CBD Manufacturing is a growing industry worldwide and it is important that manufacturers meet facility, equipment, process, and training quality standards.

These standards are collectively known as good manufacturing practices (GMP) or good production practices (GPP) and are administered by the Food and Drug Administration through an inspection program.

The CBD isolation process is a fairly complex series of steps that require engineering and quality management. We have installed equipment and trained hundreds of companies to produce isolate.

How Does CBD Isolation Work?

CBD isolation from hemp is an important manufacturing process that is used to make CBD isolate, or CBD crystal. CBD isolate is a purified form of hemp and is derived from industrial hemp. CBD isolation can also take the form of broad spectrum distillate which is a distillate without any detectable THC.

CBD isolate manufacturing involves two different potential techniques:

The first technique is chromatography which separates out the CBD from the THC while maintaining the phytonutrients, terpenes, pigments, and natural plant components that are thought to contribute to the “Entourage Effect.”

The second CBD isolate manufacturing technique involves crashing out the CBD from the matrix to produce a CBD crystal.

Then the CBD crystal is typically washed and dried so that it is also THC free but does not contain the phytonutrients, pigments and terpenes.

CBD Crystals Manufacturing Process

CBD isolate manufacturer is a specialized and technical process that fits within the overall hemp manufacturing process. The process involves:

- Growing quality hemp flower biomass that has less than 0.3% THC.

- Harvesting and drying the flower so that it can be extracted.

- Grinding of the hemp to 200-300 microns.

- Decarboxylating the hemp to activate the CBD.

- Supercritical CO2 extraction of the hemp to produce CBD extract.

- Dewaxing and winterization of the extract to make hemp oil.

- Solvent removal from the winterized CBD oil extract.

- Refining of the hemp into CBD distillate

- Production of CBD isolate by making CBD crystal

- Chromatography for high purity broad spectrum distillate.

Process typically requires a specialized facility and specialized equipment with trained operators.

This equipment includes grinders, dryers, extractors, filtration equipment, distillation machines, falling film evaporators, and of course, chromatography equipment.

Equipment to make CBD Crystals

There are many different kinds of CBD isolate machines using different kinds of chromatography. These machines include different chromatography machines that are designed to execute different methods of separation. Some examples of equipment include the following:

- Flash Column Chromatography (solvents)

- Counter Current Chromatography (liquid-liquid extraction, lle)

- Centrifugal Partition Chromatography (liquid-liquid extraction)

- High Pressure Liquid Chromatography (solvents)

- Thin Layer Chromatography

- Solid Phase Extraction Column

- Stirred Reactors

- CBD Crystal Isolate Production Machines Using Stirred Reactors

extraktLAB produces several different kinds of CBD crystal isolate production machines. The first kind of machine is an assembly of stirred, jacketed glass reactors and pumps that are assembled into an automated machine.

Stirred jacketed reactors are used around the world as reaction vessels that enable phase separation, controlled heating and cooling, and the process itself is easily automated so that crystallization can take place quickly and efficiently.

Broad Spectrum Production Machine

The second type of machine that we produce is a high-performance liquid chromatography machine. The high-performance liquid chromatography equipment uses a stationary phase that is in the form of particles that are packed into a column. The sample is pumped over the column and a separation of THC and CBD takes place. We do not use a solvent gradient unless we are cleaning the column.

CBD Isolation Methods

CBD isolation methods define the equipment, the solvent or combination of solvents to be used for extraction. Isolation methods also define critical method variables such as:

- Process temperature

- Reaction time

- Temperature, solvent gradient conditions, and time

- Pressure

- Sample condition

- Sample concentration

- Sample volume

- Flow rate

- Detection parameters

Typically the method is defined and then is tested for repeatability, robustness, reproductive capability, accuracy, precision, yield, and optionally linearity. These validation studies are critical for understanding the validity of the results using the method that has been defined by the manufacturing organization.

CBD Crystals as a Method for Sample Preparation

Crystallization of CBD is a key step in CBD isolation. One popular way to prepare a sample for separation involves crashing out the CBD into CBD crystals.

The process involves first crashing out the CBD to make crystals and washing those crystals to remove excess matrix and any lingering THC. This will give a white powder of roughly 90% purity.

The next step in the process is to concentrate the matrix by removing the solvent so that it can be injected on the chromatography column. The chromatography in this case is tuned to remove THC from the remaining CBD that is left in the supernatant.

The recovered matrix and CBD is then added back to the CBD crystals. In this way high recovery is assured and the plant matrix is preserved.

Due to the high level of processing, CBD isolate is not considered organic nor can it be certified organic. However, broad spectrum distillate can certainly be made organically and labeled organic.

extraktlab is the designer and producer of many different types of equipment for hemp processing and hemp extraction. We also produce CBD isolation machines specifically designed for CBD isolate manufacturing. This THC remediation equipment is called the pure99.

At extraktLAB, we help many operators implement equipment and workflows that enable their operations to manufacture CBD isolate and CBD broad-spectrum oils.

How to Make CBD Crystals

CBD crystals are a more refined, clean version of CBD isolate.

In today’s economy, CBD products are a hot commodity for numerous reasons. One of the most touted benefits are highlighted in areas of pain and anxiety alleviation.

CBD products are suitable for adults of all ages. Whether you have an underlying medical condition causing pain or discomfort, or you simply want to relax more to put your mind at ease, there is likely a CBD product out there for you.

extraktLAB prides itself in offering a range of information on the various formulations and compounds that CBD products primarily come in, so you can make the best choice for you. Before we delve into one of the most effective forms, CBD isolates, and even THC isolate, it is important to have a grasp on all of the facts surrounding the three primary types of formulas. CBD isolate has a level of refinement that other formulations lack.

Make Your Own Isolate CBD Crystals!

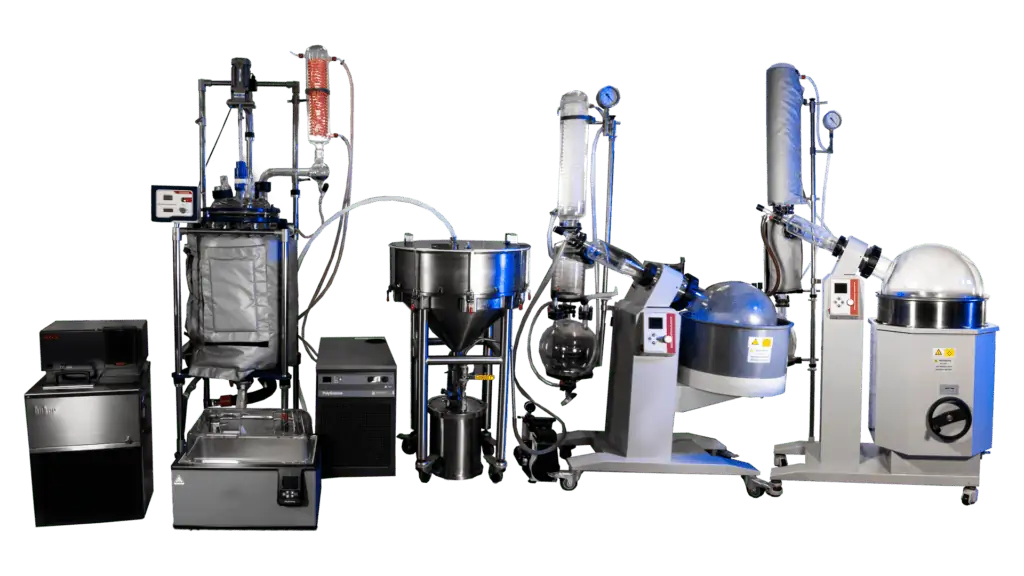

If you are ready to make the highest quality isolate CBD crystals in your extraction business, extraktLAB’s bulk CBD isolate equipment package is your best option on the market. Provided with all the necessary equipment, methods and training, this equipment package allows you to create your own high quality isolate from day one. Take a look at our CBD isolate package by clicking the image below!

What Is CBD Isolate?

A good habit to implement as a routine is to regularly check the labeling and production formulation information of every CBD product you buy. Particularly, gaining information about the company you are purchasing from is beneficial.

Learning all of the guidelines of the company, as well as their formulation techniques, will allow you to have a better grasp on the CBD or THC product you are ingesting.

High-quality CBD products will lack toxins, chemical contaminants, or inorganic compounds and the company making those products need to hold to those standards to ensure a safe, quality CBD product. extraktLAB, for example, utilizes advanced equipment to generate a cleaner product to put on the market.

Discovering how to make CBD isolate using extraktLAB’s high-level equipment and the easy-to-follow process will allow businesses to create the perfect product profile for their particular needs. CBD isolate is a pure, solid option for individuals desiring CBD effects without any delta 9 THC.

CBD Isolate – Why It’s A Good Option

There are three primary types of hemp extract based products called full-spectrum, broad-spectrum, and CBD isolate. Full-spectrum, broad-spectrum, and CBD isolates are primarily defined by their components present in the extract itself.

The main difference between the three types of concentrates is the presence of cannabinoids in the hemp extract. Depending on the levels of CBD, Delta-9 THC and other cannabinoids, a product can be called full spectrum, broad spectrum or isolate. Let’s look at each of these products in more detail.

Full-Spectrum CBD

Full spectrum CBD concentrates contain all the naturally occurring compounds from the hemp plant, including Delta-9 THC at or below 0.3%. This is a very natural product that does little to remove various plant components from the extract. This allows for a phenomenon referred to as “The Entourage Effect” in which all of the combined cannabinoids, terpenes and other hemp components work together to enhance the individual effects of each as opposed to working separately. Full spectrum formulations are great for those looking to use The Entourage Effect to their benefit, but could be risky to those who need to avoid any amount of THC in their products.

Broad-Spectrum CBD

Broad-Spectrum CBD concentrates are similar to full-spectrum products but lack THC to an extent. No detectable levels of THC can be present to be classified not only as a broad-spectrum product but also as a proper constituent under Farm Bill regulations. Remediation methods are used to reduce the level of Delta-9 THC down to undetectable levels when tested. This is an ideal choice for those wanting to use The Entourage Effect to their benefit, but need to avoid THC altogether.

CBD Isolate

So, what is CBD isolate? It’s important to remember that isolate begins with the fact that isolates are the cleanest, purest form out of the three concentrates mentioned. An extra isolation process occurs to create a near 99% level of refinement.

The advantages of utilizing isolate are endless. Determining how to make CBD isolate will result in the production of a balanced, clean product without chemical contaminants or unwanted residual elements that add no benefit to the CBD itself.

CBD isolate, much like broad-spectrum concentrates, lacks a detectable amount of THC, but also excludes all other cannabinoids, terpenes and other plant compounds – hence the name “isolate.” Since isolates undergo an extra step in processing, these particular CBD products are often more consistent in terms of potency and identity of compounds present in the extract.

How to Make CBD Isolate

Extra time and care are spent during the refinement process of isolates. After distillation, solvents are added like pentane that will separate CBD specifically from the rest of the cannabinoids and terpenes inside of a distillate extract. From there, the oil can be added to a reactionary vessel that will consistently agitate the extract with added heat until it has dried out.

In its true forms, CBD isolate processing will generate isolates in the form of refined, powdery, white crystals. The term “isolate” is coined because the CBD cannabinoid is separated from all other cannabinoids and plant compounds in order to attain nearly 100% pure, isolated CBD.

CBD isolate does not have any psychoactive components, since there is a lack of THC within the biomass. However, there is still a wide range of benefits that can be experienced when CBD isolate is consumed.

Deciphering what CBD isolate is begins with understanding how to make CBD isolate that is best suited to your specific flavor profile, level of tolerance for CBD, and desired effects. After an extensive extraction process, CBD isolate will be in a white, crystalline form. Manufacturers often choose to add an extra step to the procedure to transform the crystal structure of CBD isolate to a thin, powdered substance.

Steps On How to Make CBD Isolate

Starting the process of learning how CBD isolate is made will include the initial extraction phase.

Decarboxylation

Decarboxylation is a crucial action necessary in the process of making CBD isolate. Decarboxylation can be performed before or after extraction to convert the acidic form of a cannabinoid (CBD-A) into its active form (CBD) so that the body can metabolize and use it. This is done by applying the correct amount of heat under vacuum pressure so as not to ruin the biomass or extract. If this step is done prior to extraction, it will help the extraction process and ultimately increase the efficiency of your isolate production down the line.

Extraction

To make CBD isolate, extract the significant, organic components by use of ethanol, butane, or CO2. The hemp biomass is added to an extraction column where it is combined with the solvent of choice that will strip the cannabinoids, terpenes, fats and waxes from the plant itself. This will create a crude oil that contains all of the plant components before they are refined to create distillate and isolate products.

Winterization

Winterization will be the next phase in the procedure particularly if CO2 is the method of choice. This entails the removal of certain fatty, protein-dense nutrients from the CBD extract. Getting rid of extra wax build-up and excess, unwanted chlorophyll will enhance the quality, grade, and pureness of your CBD isolate.

Winterization happens when the hemp product is subjected to freezing or below-freezing temperatures to further separate the fats and waxes from the CBD oil. Once the fats and waxes solidify under the sub-zero temperatures, you are left with a mixture of solvent and cannabinoids that remain in liquid form.

Filtration

Once all the fats and waxes have been separated, it is now time to begin the filtration process to completely do away with the solidified plant material. Making CBD isolate will become more feasible after filtration is performed after utilizing a high-quality vacuum pump to pull the desired ethanol and cannabinoid mixture through the filter and leaving the other solidified compounds behind.

Solvent Removal

The next step after filtration is to remove the ethanol from the mixture leftover from the winterization process. This is done by applying heat and vacuum pressure to evaporate the solvent without damaging the desired compounds. The equipment used for this is often a rotary evaporator, or a falling film evaporator. Both these pieces of equipment are capable of creating a thin film which aids in the evaporation process while heat is applied under vacuum pressure to remove higher quantities of solvent from the extract.

Distillation

Once these steps in the process of how to make CBD isolate are completed, the manufacturer can move on to the distillation process to more fully refine the extract.

This process follows the same basic principle as the step of solvent removal, but is done so with more mechanical intervention to remove the last traces of solvent and other unwanted components from the final extract. This is often best performed with a wiped film evaporator that uses a mechanical wiper blade to create a thin film from the increasingly viscous liquid onto a heated column under vacuum pressure. The remaining extract is highly pure, but it is not an isolate yet.

For more information on how to make CBD isolate, determining which CBD concentrate is right for you, or simply learning more information on the topic of what is CBD isolate; contact extraktLAB to talk to expert manufacturers and chemists.

Isolation

From here, the extract can be converted into a CBD crystal isolate. This can be accomplished by isolating the CBD from the other components in the extract using processes like chromatography, or by crystallization via “crashing.” These methods fully isolate the CBD before it can be added to a stirring apparatus with applied heat until the product is dried out and a powdery CBD crystal substance is formed.

Chromatography is a useful technology that allows the separation of materials in a solution. In a CBD extract, chromatography can be used to separate the cannabinoids, terpenes, flavonoids and other hemp materials that have not been removed from winterization, filtration, solvent removal and distillation. By taking the extract and passing through a chromatography system, each individual cannabinoid can be separated and collected offering a purified form of CBD.

Crashing CBD involves adding a solvent like pentane to the extract and introducing the solution to heat and stirring. As this process is done, the CBD will solidify and turn into a powder or crystalline structure. Once the crystalized CBD has been precipitated, a cold pentane wash is performed to remove any impurities and the processor is left with a pure, solid CBD isolate product.

extraktLAB’s Equipment for Making CBD Isolate

Learning the most effective information on how to make CBD isolate involves a machine to make CBD isolate or other high-grade equipment pieces offered by extraktLAB.

The necessary categories of equipment include extraction machines, winterization, distillation, crystallization vessels and vacuums, and decarboxylation.

- Flash Column Chromatography (solvents)

- Broad-Spectrum Equipment

- Isolate Production Vessels

- Counter Current Chromatography (liquid-liquid extraction, or double liquid extraction)

- Centrifugal Partition Chromatography (liquid-liquid extraction)

- High-Pressure Liquid Chromatography (solvents)

- Isolation Filter Dryers

- Thin Layer Chromatography

- Solid Phase Extraction Column

- Stirred Reactors

- CBD Crystal Isolate Production Machines Using Stirred Reactors

- Crystallization Processing Equipment with Batch Reactors

- Simple Reactors and Vessels for Transporting Materials

To learn more about how to make CBD isolate, get machine specifications from extraktLAB’s top-notch, superior equipment. Utilize our machines to create the highest-quality CBD product on the market.

Quality CBD Crystals Begin With Quality CBD Distillate

The distillation process begins to answer the question of how do you make CBD crystals. From distillation, a procedure called crystallization takes place. While crystallization is an optional component, most manufacturers do opt for this method because it creates such a pure, CBD isolate in crystal form.

Heating and cooling tactics are utilized in this step once again. Regarding how to make CBD isolate into a crystal form relies on a reactionary vessel.

The vessel is where the CBD isolate oil is placed. The temperature is then cooled down significantly, while the churning intensity on the liquid increases. Slowly within the liquid, solid crystal components begin to form.

As the churning speed escalates, the liquid CBD isolate concentrate begins to separate from the crystals. Thus, pure-grade CBD isolate crystals are formed. CBD isolate recrystallization also utilizes solvents like ethyl or pentane to help form the CBD crystals.

Beyond this step, how to use CBD isolate is entirely up to the manufacturer. The manufacturer may choose to further process the CBD crystals into a powder. While this may be useful for edibles, tinctures, or other CBD products, a lot of manufacturers prefer to offer the highest quality of CBD isolate possible – crystals.

The discussion of what CBD isolate is can now be fully comprehended by manufacturers and consumers alike. Ask for a live demo from extraktLAB if making CBD isolate seems like a trying task. Our experts are always willing to provide live, real-time feedback and demos for individuals seeking to create high-quality isolate for their consumers. Get started on the gratifying experience of processing high-quality CBD isolate products today.