Delta 8 THC

Make Your Own Delta 8 THC

Our Delta 8 THC Packages will get you up and running fast.

Why outsource your Delta 8? Take control over the process, giving you command over things like:

- Production uptime and making sure that deadlines are met

- What to test for and where to test for unknown and potentially dangerous residuals

- Delivering awesome quality Delta 8 THC

Delta 8 Packages

To learn more information about our 50L Delta 8 Industrial Package or our Delta 8 Consumables please click the corresponding section below.

Delta 8 Industrial Package

To learn more about our 50L Delta 8 setup click here.

Delta 8 Consumables

Click here to purchase Delta 8 consumables.

What is Delta 8?

Delta 8 THC has become arguably the most popular new cannabinoid product in the hemp industry. It is a cannabinoid naturally found in hemp plants, but at much lower levels than CBD. This is the case for all strains of hemp plant. Though other strains of hemp may have variable levels of cannabinoids like CBD, all strains have relatively low levels of delta 8 making strains specific grows impractical to attain this cannabinoid. Because of this, delta 8 is derived from CBGA (Cannabigerolic acid) through decarboxylation, oxidization and isolation.

How to Make Delta 8 THC

Delta 8 Tetrahydrocannabinol is a naturally occurring cannabinoid, but as the plant itself makes very little of this compound, commercial Delta 8 THC products are lab-made from hemp-extracted CBD.

Manufacturers use various methods and techniques to facilitate the conversion of CBD into Delta 8 concentrate. Even though the process is quite straightforward, we strongly recommend that one never attempt doing it without a strong understanding of chemistry and access to a lab.

Most Common Methods Used in Creating Delta 8 THC

Short Path Distillation

Short path distillation is considered a simple method to remove residual solvents from Delta 8 THC after it is created. This method is an essential step to ensure that the final Delta 8 product is safe for human consumption and can be formulated responsibly by chemists. Still, short path distillation is not very efficient in terms of yield and costs.

The short path distillation method works for solvent removal and distillation after converting both CBD and Delta 9 THC into Delta 8 THC. If you are a hobbyist and want to try the Delta 8 THC conversion process at home it may be difficult to create a safe product without a short path distillation process. If you have the proper equipment, it is possible to make a Delta 8 product that is safe for the consumer.

However, it is critical to send a sample of your final product to a lab to confirm the contents. Unknown chemicals can possibly contain toxic or carcinogenic byproducts.

The short path distillation method includes the following steps:

- Adding Delta 8 extract to short path distillation apparatus

- Gradually bring to target temperature (205ºC)

- Allow distillation to remove residual solvents from conversion process

- Test the final product

The React Method

The react method is an advanced method of converting CBD to Delta 8 THC used by the majority of large-scale operations. It is more efficient and scalable than short path distillation.

However, we should say that cost and efficiency are optimized at the sacrifice of safety.

Using the react method requires the experience of a professional chemist, sensitive lab, and testing equipment. Short path distillation is also used in the process to purify the extract and separate Delta 8 THC from other compounds.

Here are the steps of the react method:

- Dissolve pure CBD isolate in a solvent

- Catalyze the reaction in an acid

- Neutralized the acid

- Remove the solvent

- Purify and remediate the crude extract

- Test the final product for purity

Short path distillation and react methods cover the basic principles of converting CBD to Delta 8 THC. There are also some other recipes used by professional chemists for converting CBD to Delta 8 THC, they include the Roguelab method, RockSteady modified, WKU consulting method, and Zwackelmann method.

Delta 8 Extract: Products and Consumables

Common Delta 8 THC products include gummies, tinctures, vape cartridges, distillates, and other products. When you internet search for Delta 8 gummies near me, we highly recommend looking for brands that offer the full range of tests to prove the purity of their products.

The ever-growing demand for Delta 8 THC products stimulates some of the brands popping out with new products that cannot be trusted. It is important to distinguish trustworthy companies from sketchy ones.

Beware of unethical companies when choosing Delta 8 THC products. Such companies use scammy marketing methods or lie about the test results of their products.

In addition, some companies do not test their products at all or miss key safety tests. We recommend avoiding buying products with THC effects from all those companies for safety reasons.

Complete transparency and third-party verification for a quality set trustworthy brands apart.

There are certain criteria for what makes a Delta 8 THC product safe. We want to highlight four standards that we believe are the best way to judge any Delta 8 THC brand:

- The reputation of the brand and product

- Transparent lab testing

- High-quality ingredients

- Delta 8 THC potency.

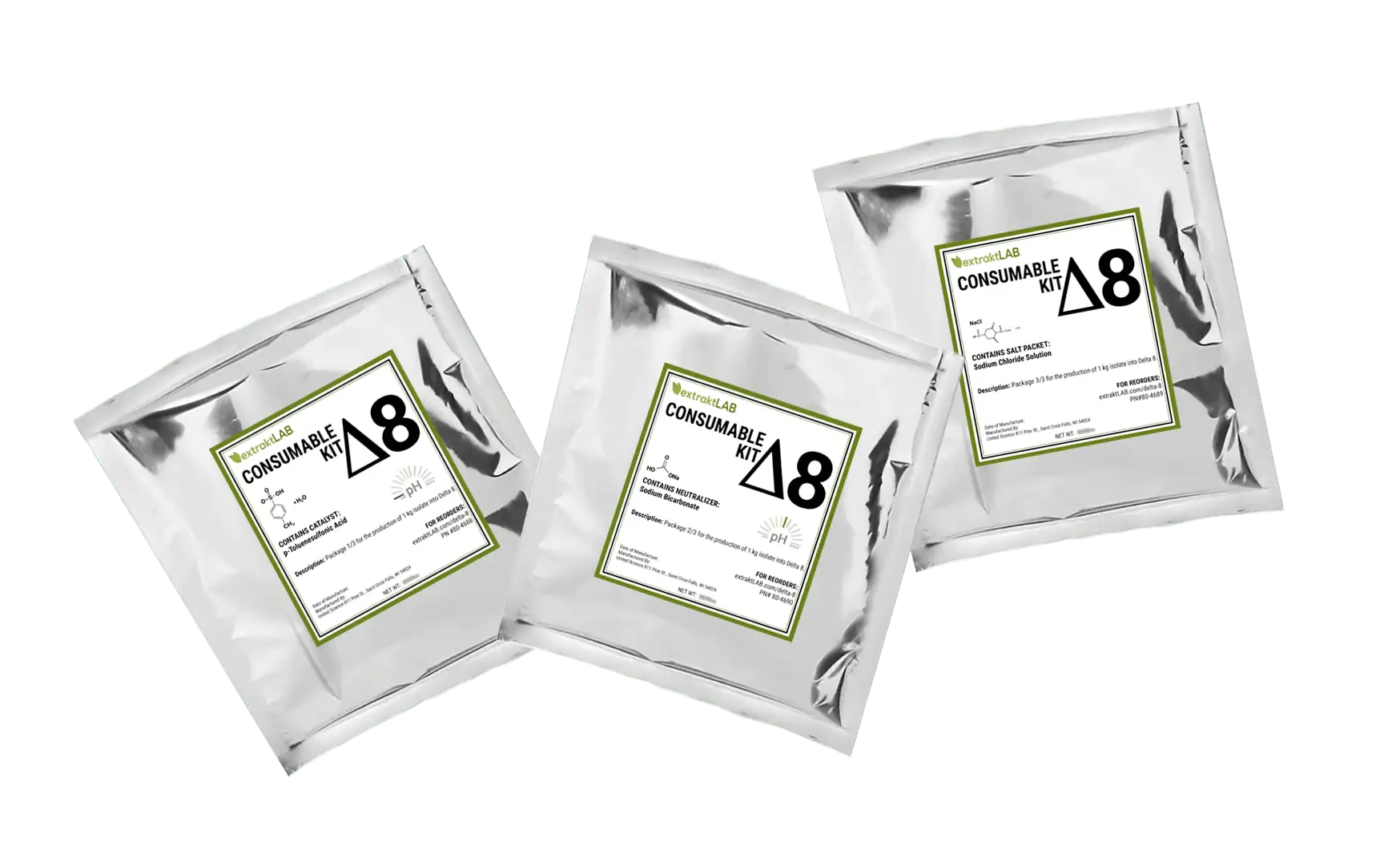

Delta 8 THC consumables are also available on the market. Some Delta 8 consumables kits include all necessary materials to convert isolate material into Delta 8 oil: purified salt, catalyst, and neutralizer. When choosing Delta 8 consumables check if all of the reagents are ACS Grade or better. It will ensure the highest quality of Delta 8 conversion in your process.

There are also DIY consumable starter packs that will enable you to start producing Delta 8 right away. A set of low-cost equipment is required in the process of CBD conversion into Delta 8 THC.

Recommended equipment includes insulation, glass reactor vessel, heating mantle, controller, condenser, stir bar, dryer, thermometer, adaptor, chiller, separatory funnel, ring stand, short path, rotovap, and hood. Some additional equipment may be needed based on your needs.

Process to Make Delta 8 Products

The science and process to make Delta 8 products from a hemp extract is easy to learn and easy to execute with the right information like extraktLAB’s course, and the laboratory and consumable kits. The basic process requires quality hemp derived CBD isolate that has a cannabinoid content of greater than 95%.

- Isolate starting material is mixed with an organic solvent and is heated.

- The catalyst is added while stirring.

- After heating and stirring for about an hour, the solution will turn a dark amber and become viscous.

- The solution is allowed to cool and is poured out of the flask into a separatory funnel containing a washing solution.

- The solution is washed repeatedly with water, neutralizer and salt solution.

- The solvent is removed from the oil by boiling or roto-vaping.

- The oil is improved in appearance and quality with a short path (wiped film or glass ware) apparatus.

This process will produce Delta 8 oils that are approximately 80-85% potent. The oil is then diluted to remove any excess Delta 9 cannabinoids or is diluted to keep the Delta 9 below 0.3%.

What Makes a Good Delta 8 Manufacturer?

When it comes to a quality product, you have to be able to determine a reputable delta 8 manufacturer. Because of the legal status of delta 8 THC, a delta 8 manufacturer that is not adhering to the rigid laws and regulations necessary to create a safe and legal product should not be viewed as a trustworthy business. Here are some things that should be considered when assessing a reputable manufacturer of delta 8:

Legal Practices

The legality of Delta 8 products has been questioned since its popularity began to spike. Although it is psychoactive, as a hemp derived product that is not delta 9 THC, it is technically legal under the 2018 Farm Bill.

But, any delta 8 manufacturer is likely to be under close watch to ensure that they are operating legally. Making sure that a company has clear and dedicated legal guidelines that they follow is essential to determining a reputable company making delta 8. A good example of this is making sure that they have a clear age restriction on the sale of their products and ensuring that nobody under that age limit is capable of buying delta 8 products.

Ensuring legal levels of delta 9

Looking back to the 2018 Farm Bill, a legal hemp derived product must not contain more than 0.3% of delta 9 THC. Because of the process of making the product, a delta 8 manufacturer has to make sure that the levels of delta 9 THC in any given product are below that 0.3% threshold. This comes through proper processes and rigorous testing.

The issue with many delta 8 manufacturers is that many of them do not uphold the delta 9 threshold and ship their products to their customers anyway. In fact, we have analyzed a number of delta 8 manufacturers and tested their products in our podcast episode. Take a look for yourself and keep this in mind when deciding a reputable delta 8 producer.

Quality control (testing for residuals)

Not only is the quantity of delta 9 THC a vital consideration for a quality delta 8 product, but testing for residuals and unknowns is equally important. A quality delta 8 manufacturer will be transparent about third-party testing and will openly display batch records and test results for all of their products.

If a manufacturer of delta 8 products is not clear about their testing efforts and batch records, it is always best to steer clear of that brand. Take a look at the same podcast episode mentioned above to see what we came up with when we tested a few different delta 8 brands.

Reputable Delta 8 Manufacturers

Of course, there are plenty of delta 8 manufacturers that are following these practices and making a safe and quality product. Here are a few noteworthy options of delta 8 companies that are reputable:

Exhale

- Utilizes CO2 extraction

- Organic & vegan ingredients

- Full production transparency

BudPop

- All natural ingredients

- No additives: PEG, VG, Vitamin E, PG free

- Encourages healthy lifestyle choices

Delta Extrax

- Utilizes CO2 Extraction

- Full production transparency

- Highly effective according to user reviews

Is Delta 8 Safe?

Safety Consumptions and Considerations

We have already listed above the criteria of what makes a Delta 8 THC product safe. The reputation of the brand and product, transparent lab testing, high-quality ingredients, and Delta 8 THC potency make Delta 8 THC products consumption safe.

Among major safety considerations for the use of Delta 8 THC products should be mentioned irresponsible production, lack of regulatory oversight, and limited laboratory testing.

When manufacturers make errors in the Delta 8 THC creating process, they typically use low-grade materials and do not perform proper testing, and thus the sample can become contaminated.

Some of the Delta 8 THC byproducts and impurities can actually be harmful and toxic. In many cases, nothing is known about the health effects of Delta 8 THC impurities.

Therefore, CBD material and the solvents, and acids used in the process of Delta 8 THC creation should be pure. Otherwise, there is a high risk of contaminants and byproducts that are nearly impossible to determine.

Another potential safety risk is inaccurate Delta 8 THC conversion process. If the conversion process is not 100% accurate, the product will be not a pure Delta 8 THC but a mixture of Delta 8 THC, Delta 9 THC, and other cannabinoids. Without proper THC remediation, a product will contain illegal concentrations of Delta 9 THC.

Some manufacturers use strong bases such as metal catalysts for neutralization of Delta 8 THC. Even though they may claim that their products do not include any harmful reactants, nobody is measuring the pH of such Delta 8 products or testing them for strong acids and residual metals that are left behind.

Delta 8 THC production requires chemistry experience, access to adequate safety and laboratory equipment, and taking all the precautions involved with safety.

Therefore, when choosing Delta 8 THC for safe consumption, check if the brand is a responsible Delta 8 THC manufacturer who uses high-quality and pure ingredients, follows 100% accurate conversion process and safety precautions, as well as conducts transparent third-party lab testing for purity and safety.

Delta 8 Remediation

Removal of Delta 9 from Delta 8 is very difficult due to the fact that both cannabinoids are isomers, but not impossible!

Delta 8 THC Effects

Like all hemp compounds, delta 8 has its own unique effects. Many of the reported effects by those who have used both delta 8 products and delta 9 products claim a similar psychoactive response from both cannabinoids. While the effects of delta 9 products include euphoria, relaxation, and appetite stimulation among others, the effects of delta 8 products tend to be the same as reported from users, but at a more mild level. For this reason, many have turned to delta 8 as opposed to delta 9 because its effects are more mild, and manageable for those sensitive to psychoactive products.

Legal Status of Hemp Derived Delta 8

Delta 8 is a cannabinoid found in the cannabis plant in lower levels. The delta 9 cannabinoid is illegal in most states under the Controlled Substances Act. Hemp, on the other hand, was made legal federally by the 2018 Farm Bill. Industrial hemp is monitored to have no more than 0.3 percent Delta 9. All products that are extracted and used from cannabinoids in this legal plant must end with no more than the standard 0.3% Delta 9. Delta 8 is one of over 100 legal cannabinoids in hemp, meaning it is a legal substance within the United States.

Consumables

Included with the Delta 8 Startup Package is a Delta 8 Consumables Kit. This includes the necessary materials to convert 1kg of isolate material into Delta 8 oil. Included in the kit are:

- 1 package of purified salt

- 1 packet of catalyst

- 1 packet of neutralizer

All of the reagents included in the Delta 8 Consumables Kit are ACS Grade or better to ensure the highest quality Delta 8 conversion in your process.

Delta 8 Consumables and DIY

This package includes a consumable starter pack that will enable you to start producing on your very first day. This process requires a low cost set of equipment . The recommended equipment list includes the following:

- Glass reactor vessel

- Insulation

- Heating mantle + controller.

- Stir bar

- Condenser

- Dryer

- Thermometer plus adaptor

- Chiller

- Separatory Funnel + Ring Stand

- Short Path

- Rotovap

- Hood

You may need additional equipment based on your needs.

Courses

Consumables package: purified salt, catalyst and neutralizer

For information, tips and instructions for use we recommend you sign up for two of our free exraktUniversity Courses:

- Delta 8 Mini Course

- What is Delta 8 THC

- Delta 8 vs. Delta 9

- How to make Delta 8

- Formulation Mini Course

- Dilution calculators

- How to read your analytical results

- Ingredients

Delta 8 50L Industrial Startup Package

This 50L reactor is tailored for Delta 8 production. Equipment features air pumps, heater, solvent reservoirs, manual valves, helium fluid transfer, and overhead stirrer with air motor

- Manual System

- 50L Stirred Reactor

- Air Motor

- Heat Exchanger Coupling

- High Temperature Ultra Fast Oil Recirculating Heater

- Delta 8 Consumables

In addition, you will need to provide compressed air, connections, helium, solvents and code compliant room.

- Heater Power Requirements: 18 kw, 208V, 3 phase

- Heater Location: Heater to be located outside of room

- Compressed Air: Dry, 80 psi, 10 scfm

- Footprint: 48x48x60 in

- Gas Pumps: 50 lb cylinder industrial grade helium + regulator

Features

Industrial Delta 8 Package

Includes information, tips and instructions for use

Production Training Videos

- Production Training Videos

- Step by step instructions

- Safety tips

- SOPs

- Formulation Mini Course

- Dilution calculators

- How to read your analytical results

- Ingredients

THROUGHPUT: 3L Per Hour

Frequently Asked Questions

How long is the post contract lead time for installation, setup and training?

Our lead time for the Lab is 5 Weeks. After signature, we will need this time to put the package together. We cater these contracts specifically to our customers and until we have a signature and finalization we do not start on putting the package together due to how often we are changing our contracts. The sooner the signature and finalization, the sooner we can get everything out to you.

You advise to test all raw material and to test after each stage of production. Can you clarify what tests can be performed in house and what needs to be sent out?

Yes, you need to do testing on your product frequently. There are many factors that dictate how frequently testing is required. For example, we recommend testing a batch every 10 kilos made to ensure consistent IF that product is from the same crop. If it is from different crops, this will likely increase the amount of testing you will need to ensure consistency. This kind of testing is performed in house to measure purity and potency so that production can continue. Third-Party testing is necessary for approval of a final product.

The package states we must provide adequate ventilation. Can you please clarify this? Are we going to need a ventilation system with exhaust motors and air filters and scrubbers?

No, you will not need a ventilation system with exhaust motors. Adequate ventilation here means if you are in an enclosed room that you have some sort of venting/fan to circulate and not trap everything in that enclosed room.

How much helium use can we anticipate if we are operating at 300 Liters of production per week?

You will spend roughly $150/Week for industrial grade helium at a production rate of 300L per week.

Is equipment maintenance something we can perform, or do your techs provide maintenance as part of the package and contract?

The equipment that comes with the Delta 8 Conversion Package does not require consistent maintenance. This equipment requires cleaning regularly after use and between batches. This knowledge and training is part of the package that we will share with you during setup.

Do we have the ability to adjust the frequency of the chemical shipping schedule?

Yes

After the initial set up and installation, what does extraktLAB support consist of?

There will be tech support/help available to you at no cost whenever you need it! Additional fees are associated with further on-site support.

Will extraktLAB identify and ensure that we will meet all federal, state, and local requirements and regulations for this lab and production?

As part of the consulting and set up commitment extraktLAB can help to maintain GMP Compliances, State Regulations or other URS that you are looking for.

What is the cost of raw materials to convert 1kg of isolate to delta 8?

It will cost $125 US in reagents per Kg of Iso converted.

Do I need to lab test after every liter created to make sure it is good?

Not every liter but you will want to test every batch.

Will the equipment that is included create a final sellable product at the end?

Yes, Delta 8 is ready to go as an oil ingredient product with this lab setup.

Is there more work required after isolate is converted?

Once it is converted you will still need to remove the solvent using a RotoVap or some sort of Falling Film Evaporator. (This does not change the yields)