How to Remove Dark Color from Ethanol Extracts

The Issue of Dark Color in Ethanol Extracts

A common concern for ethanol extract producers is the dark color often resulting from the extraction process. One such customer inquired about ways to improve the appearance of their extracts, which were coming out dark due to the ethanol extraction method.

This dark coloration is typically caused by chlorophyll and xanthophyll being extracted from the biomass during the process. These compounds contribute to the deep green color seen in ethanol-based extracts, as opposed to the lighter appearance of oils produced by other methods, such as supercritical CO2 extraction.

Removing Chlorophyll from Ethanol Extracts

When it comes to extracts, chlorophyll is an undesirable plant compound, to say the least. The issue for ethanol extractors is that chlorophyll is highly soluble in ethanol and will likely find its way into an extract at some level. This makes it very difficult for ethanol extractors to produce a distillate that does not contain chlorophyll and other phytochemicals.

In terms of extract, residual chlorophyll can create a dark, undesirable color and potentially lesser flavor and aroma in an end product. So, removing chlorophyll from ethanol extracts is a crucial part of creating a desirable product, and there are many ways to do this.

One of the most common methods of removing chlorophyll from an extract is activated charcoal; however, this method has some drawbacks, and alternatives could prove more desirable for extractors.

Activated Carbon and Its Drawbacks

Activated carbon (or activated charcoal) is one of the most popular options for removing chlorophyll and other unwanted non-active pigments in ethanol extracts. While activated carbon is quite effective at pigment removal, it is also very effective at removing active compounds. The large pore diameter distribution and particle friability of activated carbon also result in a much smaller yield.

Another problem with activated carbon is its natural origin and the contamination it carries. Activated carbon is typically derived from coconut shells, bitumen, or wood. These products have significant ash content and heavy metals. When the carbon breaks up under use, these metals distribute throughout the oil as very small particles. They become very hard, if not impossible, to remove via filtration. Thus, they end up in your extracts.

However, the most overlooked aspect of using activated carbon is the solvation and dissolution of benzopyrenes into the extract. Benzopyrenes are harmful because they form carcinogenic and mutagenic metabolites which intercalate into DNA, interfering with transcription. They are considered pollutants and carcinogens.

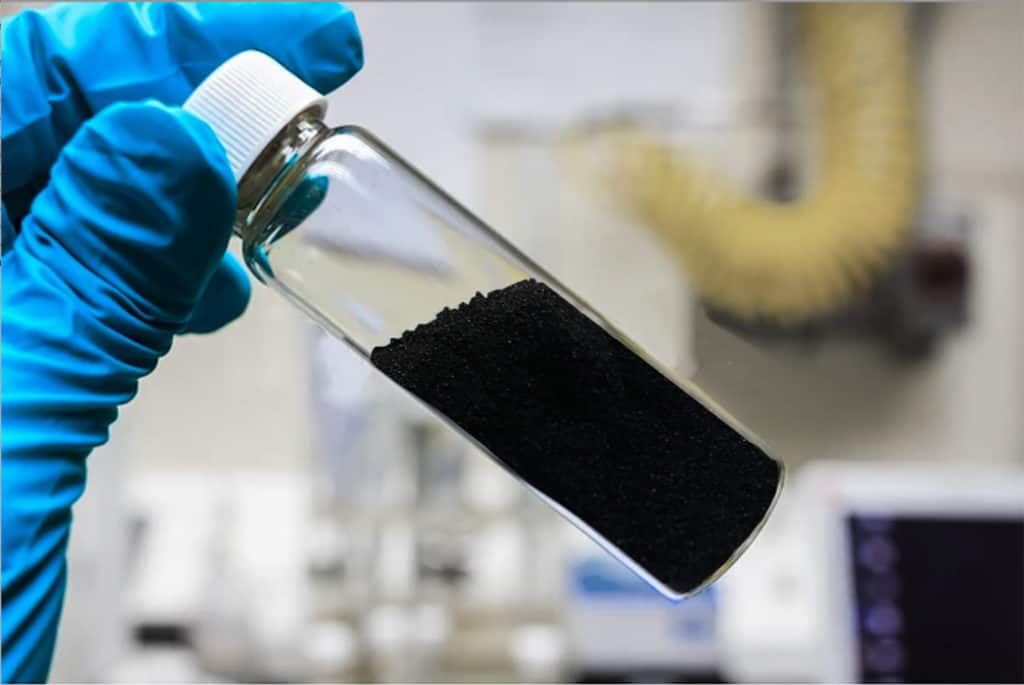

How to Remove Chlorophyll With carbonX

carbonX offers an effective solution for removing chlorophyll from extracts. Unlike natural products, carbonX is engineered by depositing carbon onto a porous substrate, ensuring reliable performance.

One key advantage is that carbonX’s substrate doesn’t break apart, which means it won’t introduce any ash or particles that are difficult to filter out. Additionally, carbonX is pre-washed to prevent any unwanted substances from contaminating your extracts.

There are two main ways to use carbonX:

As a filter cake: Use carbonX with a DrainDroyd system to dewax up to 5 liters of oil in just 5 minutes.

Dispersively: Simply mix carbonX into your extract, allow it to work, and then use the DrainDroyd to filter it out.

The Ethanol Extraction Conundrum

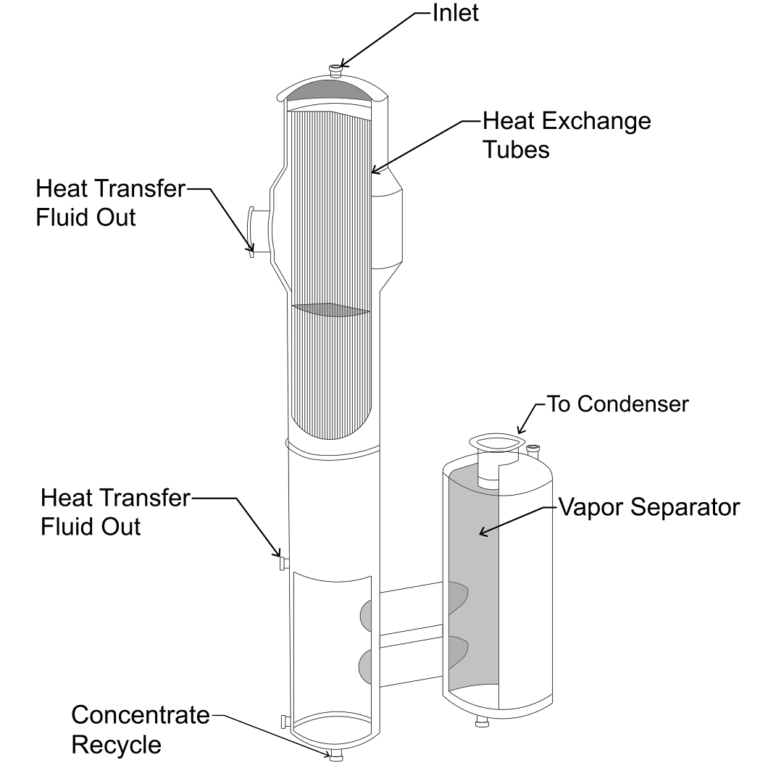

If you extract hemp plant material with warm ethanol, pigments, and waxes will be co-extracted. These pigments typically taste bad and give the oil a poor-quality appearance. Rotary evaporators (rotovaps) or stills are typically used to remove the ethanol, but the pigments, waxes, and poor-quality elements remain in the extract.

QWET Method

To minimize the extraction of non-active compounds, some people use extremely cold ethanol chilled to below -20°C. The quick-wash ethanol method, the QWET method, is the most common cold ethanol extraction. Chilling the ethanol lessens the solvent’s hydrophilic properties, thus minimizing the extracted waxes and pigments.

However, as with any other chemical process, friction factors increase exponentially as the process gets colder. At the same time, diffusion coefficients of the actives in the ethanol plummet. While chlorophyll extraction and plant waxes are reduced, the absolute amount of active compounds extracted (cannabinoids, terpenes, etc.) also decreases significantly. In short, you get to choose: low recovery or high pigments.

Ethanol Is a Flammable Solvent

Another important aspect of ethanol is its high degree of flammability. Before attempting to build a process based on large amounts of flammable liquid, familiarize yourself with the regulations around storage and use of ethanol. You should always consider the infrastructure requirements and permit barriers to using large volumes of ethanol.

If you’re planning a large-scale ethanol extraction operation, read our post about things to consider when scaling up ethanol production.

The National Fire Protection Association has published NFPA 30 guidelines for required explosion-proof fixtures and infrastructure. OSHA regulations are also available here.

Contact Us To Get Started Today