Solvent delivery is an often overlooked aspect to the extraction process. When using a solvent like supercritical CO2, an efficient CO2 system capable of supplying your extractors at the correct pressure and temperature all while maintaining a safe and efficient supply. In this article, we discuss three CO2 systems, bulk tanks, cylinders, and microbulk tanks, and how they measure up to the extraktLAB’s CO2 system with the CO2Cage and CO2 Pump solution.

Reviewing Common CO2 System Methods

Unfortunately, most companies in this industry make the CO2 supply your problem. In other words, it’s “out of scope.” This is not the case with extraktLAB. We have seen customers struggle with the detailed requirements of CO2 conditioning for their extractors. We have the perfect CO2 supply solutions for any CO2 extractor.

There are essentially four options that can be utilized for CO2 supply: 1. Delivery of cylinders. 2. Bulk tank feed, 3. Microbulk tanks or 4. extraktLAB’s CO2 cage. We have found that because gas companies are not familiar with certain extraction applications, they confidently say that they can deliver a CO2 supply solution, but you may come to learn over a period of weeks or months that they will need to learn the application and details. This essentially means that they will miss the key requirements and fail to apply those to the solution. We have seen it happen many times.

In order to understand the benefits and drawbacks of these certain applications, we need to go through them each in detail:

Cylinder CO2 Systems

Let’s talk about cylinders first: Running a CO2 system off of cylinders is incredibly inefficient because you never know when your tanks are empty so you will need to keep a stock of CO2 cylinders on hand. Secondly, you can typically only get 65-75% of CO2 out of the cylinder because it will lose pressure as the CO2 is depleted. Third, cylinders are quite heavy and essentially dangerous to move around. However, the most important factor is the pressure coming from the tanks will depend on the temperature. If the temp is too low, the reliability of the extractor’s overall performance is compromised. Tanks are often filled the same day they are delivered. So, the inlet pressure is too low because the temperature is too low.

Bulk Tank CO2 System

Secondly, Bulk CO2 tanks. Bulk CO2 sources such as 25 ton tanks have the same issues that microbulk tanks have. You will need to step up the pressure to keep the fluid liquid so it can be pumped. If you want to have a gas company provide you a bulk CO2 tank, not just any tank is appropriate. Chances are very high that they will inadvertently sell you the wrong unit that will not work properly for CO2 extraction.

Microbulk CO2 Systems

Finally, microbulk tanks: Running a system off of a microbulk tank also does not work very well because the inlet pressure must be higher than 300 psi. You would also need a step up pressure pump or recirculating system to make that work. However, because microbulk tanks are not refrigerated, the CO2 will warm up upon recirculation, and this leads to a very high CO2 waste as the pressure builds to over 300 psi in the microbulk tank.

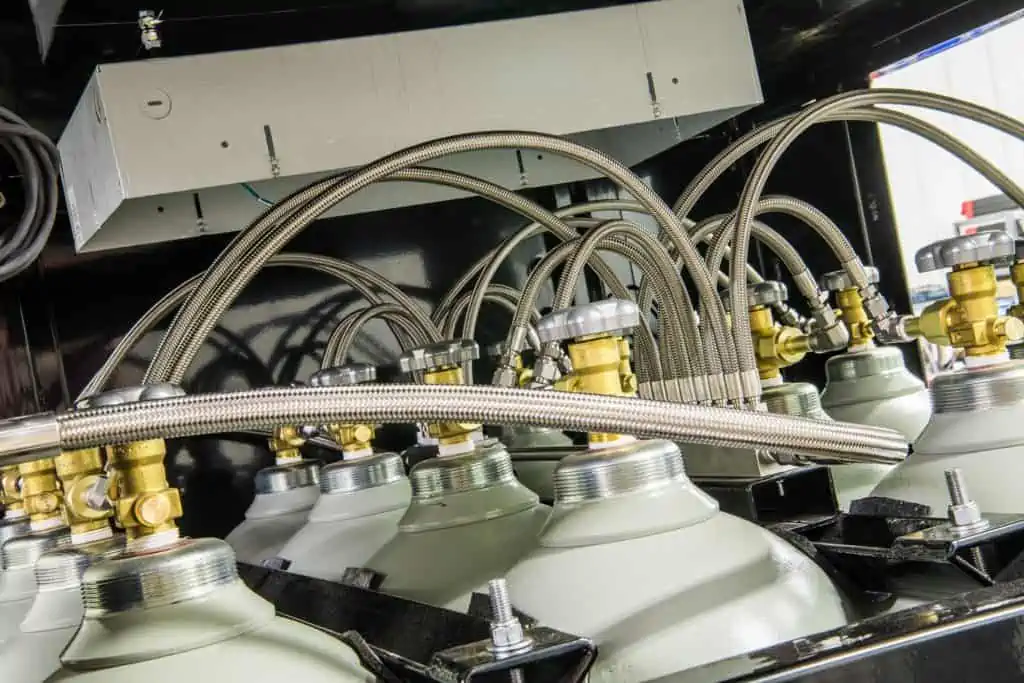

The CO2Cage CO2 System

Finally, we have the extraktLAB CO2Cage solution. Our microbulk CO2Cage and CO2 pump solution solves all of these problems by conditioning the CO2 supply to deliver 800 psi+ CO2 every time. Whatever system you are running, you need a reliable CO2 system that monitors the CO2 usage, gives an alarm when CO2 is running low, maintains the inlet pressure, tracks the lot of CO2 delivered to the extractors, maintains the CO2 fluid pressure, monitors for leaks and automatically vents and alarms in the event of a leak, and is compliant with CGA and fire code requirements for venting. All of these are accomplished when implementing the CO2Cage solution to your process.

In terms of filling the CO2 cage, you can fill it using our CO2 pump from a beverage CO2 service truck source, a microbulk, or a large bulk tank. We also provide complete cryogenic fluid piping and engineering solutions for your facility in the event you need to have your bulk tank located in a different area than your extractors.

If you are operating your extraction business using CO2, it is essential that you supply your extractors with CO2 at exactly the right temperature and pressure, use it as efficiently as possible, and do this all as safely as possible.