Distillation Equipment Buyer’s Guide

Have you considered the differences in equipment used for thin film distillation? In this article, we compare the benefits and detriments of wiped film distillation to short path distillation equipment for CBD oil processing.

Clarity and potency are important to consumers in search of products made from pure CBD distillates and isolates. However, businesses who produce these products have many additional factors to consider in the hemp extraction process. Throughput, cost, scalability, quality of the product, maintenance, automation, GMP compliance and overall efficiency are just a few of the things that producers need to scrutinize when considering equipment for molecular distillation.

In this article, we compare and contrast the different thin film distillation techniques that are in widespread use to produce CBD distillate and show how wiped film distillation is a clear winner for scalable, GMP operations.

Comparison of Wiped Film, Short Path and Thin Film Distillation Equipment

The following table is a summary of the results from this review. It compares desirable features for short path distillation SPD, thin film short path distillation, and our clearSTILL 400 wiped film evaporator distillation technology and rates each technique accordingly.

Table 1. Comparison of review rating for short path distillation, thin film distillation, and clearSTILL distillation equipment.

|

Desirable Characteristic |

Short Path Distillation |

Thin Film Distillation |

clearSTILL Wiped Film Distillation |

|---|---|---|---|

|

More Automation |

+ |

++ |

+++++ |

|

Continuous Operation |

+ |

+++ |

+++ |

|

Data & Batch Logging |

+ |

+ |

+++++ |

|

Reduced Maintenance |

++ |

+ |

+++++ |

|

High Robustness (1) |

+ |

+ or +++++ |

+++++ |

|

Reduced Contamination |

+ |

+++++ |

+++++ |

|

Better Scalability |

+ |

+++ |

+++++ |

|

Easier Cleanability |

+++ |

++ |

++ |

|

Continuous Vacuum |

+ |

+++++ |

+++++ |

|

High Throughput |

+ |

+++ |

+++++ |

|

Reduced Product Reactions (2) |

+ |

+++++ |

+++++ |

|

Light Yellow Distillate |

+++++ |

+++ |

+++ |

|

Product Potency Consistency |

+ |

++++ |

+++++ |

|

Built-in GMP Compliance |

+ |

+ |

+++++ |

- Wiped film distillation and SPD can both be glass and therefore have the same robustness. Stainless versions of either will obtain a better rating.

- Isomerization or degradation reactions.

As the table shows, the key advantages of wiped film technology is because it preserves the product, is more efficient, is continuous, and is also scalable. Short path distillation on the other hand is a batch process, does not scale very well because it is slow, and is known to degrade the product within the still.

The clearSTILL 400 distillation machine is an innovative wiped film molecular distillation technology that is built on the foundation of a wiped film still but adds many of the features that operators and manufacturers need to make their systems compliant, more efficient, and more automated.

Let’s get into more details. The following discussion seeks to explain the basis of the comparison and provide insight as to when a short path apparatus shines and when wiped film equipment is more desirable. We will first examine the similarities of the two techniques.

Wiped Film and Short Path Distillation are Similar In Their Overall Goal

Distillation techniques have been used for years in botanical extraction and commercial industries. In fact, the essential oil industry has been using this technology for many years before the 2018 Farm Bill allowed for the legal extraction and distillation of CBD from hemp. In both industries, the process is very much the same.

First, a word about terminology. Most laboratory glass based “short” path apparatus that are on the market today are mislabeled. Since the condenser is external to these units, they fall out of the definition of what is considered a short path. Since the entire extraction industry uses this vernacular, we will too; however, outside of the industry, the term “short path” may mean something different.

Short path and thin film distillation equipment operate in a similar fashion to separate liquid mixtures through differences in boiling points. Though their methods are different, both wiped film and short path equipment both will produce clear, light yellow distillate with potencies ranging from 60-90%.

To decrease boiling point temperatures, both equipment styles utilize vacuum. By decreasing pressure, vacuum distillation lowers boiling points and avoids prolonged exposure to the heat source. This prevents the chance of damage to desired materials during the evaporation process and avoids the production of degradation or isomerization byproducts. Coupled with the creation of a thin film, molecular distillation allows producers to create a potent, clear distillate that is rid of extraction solvents.

Pros and Cons of Wiped Film Distillation and “Short Path” Distillation Equipment

Though both of these processes are essential for a quality extract product, and are similar in concept, short path and wiped film both have different advantages and disadvantages. The following table is an annotated comparison of the features, pros, and cons of the techniques and equipment.

Table 2. Annotated comparison of the pros and cons of short path distillation and wiped film distillation (clearSTILL).

|

Short Path Distillation |

clearSTILL Wiped Film Distillation | |

|---|---|---|

|

Automation |

Manual methods, Manual changeover. |

Method automation, Fill automation. |

|

Operation |

Discontinuous, batch feed. |

Continuous feed. |

|

Data Logging |

N/A |

Method type, Operator, Batch, Mass flow, Vacuum, Temperatures, Reservoir level, Maintenance, Calibration, Optional detection. |

|

Maintenance |

Need to change vacuum pump oil daily, vacuum grease. |

Maintenance free vacuum pumps, replaceable seals. |

|

Robustness of Equipment |

Glass breakage is common. |

Stainless construction reduces or eliminates glass breakage. |

|

Contamination |

Vacuum grease contamination is common but can be mitigated or reduced with proper technique |

Stainless steel, PEEK and PTFE wetted materials do not leach and produce no contaminants. |

|

Scalability |

Requires many apparatus to scale. Practical limit of 5L vessels even though 20L vessels are available. |

Easy to scale and feed directly with fracTRON. |

|

Cleanability |

Easy to disassemble, cleaning of glass more difficult than steel. |

Automated cleaning methods, 304 SS, surfaces. More difficult to disassemble. |

|

Vacuum |

Break in vacuum between runs or when taking different fractions. |

Continuous. |

|

Throughput |

Low compared to wiped film. Multi passes are sometimes required. |

Higher throughput than short path. Single pass. |

|

Fractionation |

Can fractionate low boiling solvents from cannabinoids. Can’t separate cannabinoids. |

Can not fractionate. Can’t separate cannabinoids. |

|

Product |

Degrades product due to long time exposure to high heat. |

Short residence time does not isomerize or convert or degrade cannabinoids. |

|

Product Consistency |

High potencies can be achieved, highly variable and hard to maintain batch-to-batch potency consistency. |

Consistent batch-to-batch potency achievable. |

|

Color |

Yellow color. |

Yellow-amber color. |

|

Off line records & tracking. |

On board tracking and certification of: Calibration of sensors, Maintenance records, Printing & data storage, Run Methods, Method change log, User level traceability, Data traceability, Data integrity, Batch record traceability, Materials traceability, Cleaning methods, Surface finishes. |

As is shown in the table, wiped film distillation has many key advantages but short path equipment is not without its unique characteristics. As with any production technique, there are always trade-offs.

The clearSTILL 400 distillation machine is an innovative wiped film molecular distillation technology that is built on the foundation of a wiped film still but adds many of the features that operators and manufacturers need to make their systems compliant, more efficient, and more automated.

“Short path distillation equipment is laboratory glassware apparatus whereas wiped film equipment is made for an industrial setting and can be deployed in manufacturing operations.” – Dr. Jon Thompson

An advantage SPD has over WFD is it can do a better job at creating a clear distillate with a lighter yellow color. It also has the ability to fractionate whereas WFD is not really set up to do that. The other key advantage is one of cost. A SPD unit can range from $200 – $20,000 USD whereas WFD units start around $100,000 USD.

The key advantages that WFD has over SPD are scalability, product consistency, throughput, automation, GMP compliance and continuous operation. This is why many manufacturers choose this kind of equipment to deploy in their operations.

clearSTILL 400 is Game Changing Wiped Film Distillation Technology

As is shown in Table 1., clearSTILL 400 wiped film technology is highly advanced compared to state of the art wiped film distillation equipment. The technology employs automated methods, maintenance free vacuum systems, data logging and mass flow monitoring for better consistency and control of the end product. However, there are many other advantages.

First, clearSTILL 400 gives hemp producers the opportunity to perform two independent distillation passes in a single contained cycle. Traditional WFD distillation equipment requires each distillation pass to be performed in a separate cycle.This creates a bottleneck in production and risks contamination, or product waste between transfers. With dual stills capable of a continuous process throughput of 4-6 L per hour, the clearSTILL 400 is capable of doubling throughput and halving labor costs compared to single stage systems.

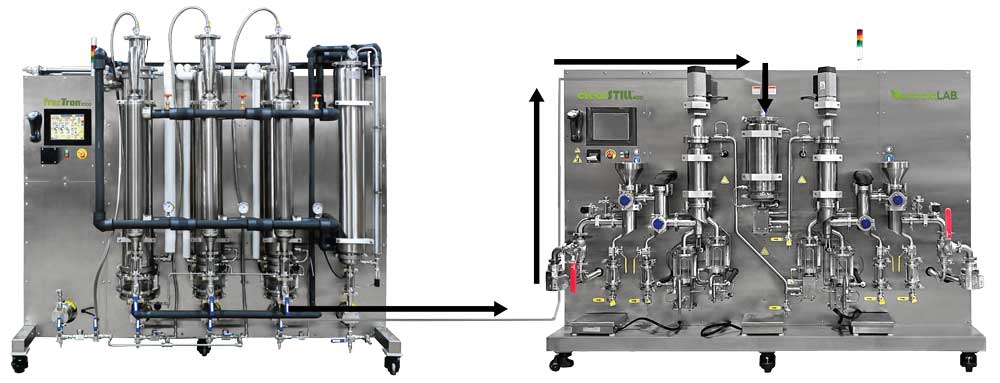

Second, when integrated with our fracTron 1000, one can continuously feed extracts obtained from ethanol extraction or winterization into the fracTron 1000 to remove the ethanol and then continuously feed material into the clearSTILL 400 according to the following diagram:

The clearSTILL 400 also addresses the standard issue of cleaning downtime compared to standard wiped film equipment. A programmable cleaning protocol can be scheduled directly into the machine. This negates the opportunity for missed cleaning cycles or contamination that could potentially create wasted material due to contamination.

There is a clear maintenance advantage for the clearSTILL 400. The equipment uses vacuum pumps that do not require oil for operation. Most vacuum pumps typically use an oil ring to produce a proper seal.This allows for volatile components that don’t condense during degassing to follow vapor flow and contaminate the lubrication needed for the pump. This would require additional cleaning and maintenance – meaning more down time. Utilizing dry pumps, the clearSTILL 400 avoids that issue entirely.

The clearSTILL 400 is also designed with the GMP manufacturing operation in mind. On-board tracking of user, method, lot, batch, calibration and maintenance streamlines quality reporting. On skid barcode-enabled entry of meta data including batch and user data enable paper and electronic trails that preserve data integrity. GAMP and 21 CFR Part 11 compliant, the integrated data logging and archiving system puts the clearSTILL 400 a cut above its competitors.

Contact Us To Get Started Today