After grinding, decarboxylating and extracting hemp the next important step is to filter and winterizing wax. In this article, we explain why this step is crucial to supercritical CO2 extraction.

Grow, harvest, test, grind, decarboxylate, test again, extract… What’s next? Depending on your extraction method of choice, it is very likely that the next step in creating your hemp concentrate will involve winterizing wax and filtering your mixture to begin the distillation process.

Because the crude oil that is created with methods like supercritical CO2 extraction will often contain waxes and lipids, it becomes important to remove them to create a quality final product for the consumer.

So, let’s take a look at this important process and why supercritical CO2 extraction benefits from it.

What is Winterization?

Winterization is the process of removing fats and waxes from the hemp extract. The process involves dissolving the CBD oil coming out of the CO2 extractor in food grade ethanol and subsequently chilling the ethanol oil mixture down to -20 degrees Celsius. The fats and waxes are less soluble at those temperatures and they will precipitate while the cannabinoids remain in solution. The fats and waxes are then filtered before solvent removal.

Why Winterizing Wax is Important

Because extraction will also take out plant waxes and fats with the desired cannabinoids, winterizing wax is critical to create a product that is desirable to the end user.

Winterizing wax and then filtering oil is important to remove the fats and waxes that would otherwise cause flavor and consistency issues. In vape products, for example, fats and waxes can cause a harsh flavor and can even cause irritation of the throat as well. This can all be mitigated by winterizing wax and filtering it out.

By winterizing wax, you solidify the plant fats and waxes at frigid cold temperatures while the desired components remain in a liquid form. This allows for a vacuum filtration method to be used that pulls the oil through a filtration medium that traps the waxes, fats and chlorophylls while allowing the desired cannabinoids and terpenes to be collected. This results in a higher quality product that is desirable and profitable to the end customer.

Why Winterize and Filter Your Oil?

Depending on the product that is being created, remaining waxes and lipids can cause a number of issues for both producers and consumers:

For the producer, remaining waxes and lipids can dilute product potency, and cause a lesser quality distillate overall. Quality and clarity of a hemp extract often go hand-in-hand, and remaining waxes can cause a final distillate to be cloudy or of undesired consistency – not the result a producer wants to see after all the hard work.

For the consumer, waxes and lipids left in an extract can result in a shotty product as well. For example, smokeable hemp extracts or “dabs” as they are often called can come in the form of what is called “shatter” given its translucent clarity and breakable consistency similar to glass.

Both clarity and consistency mean quality shatter and a happy customer, but when residual waxes are left in the product it can cause what is called nucleation making that clear, brittle shatter turn into a soft, sticky opaque consistency.

Furthermore, fats and waxes left in any hemp concentrate can be harsh or have undesirable tastes when smoked or vaporized. Because of this, it is very important to properly winterize and filter those remaining waxes and lipids. And, there are many methods to do this.

As a proud proponent of supercritical CO2 extraction, extraktLAB does not use denatured ethanol for an extraction method for a number of reasons. However, a common method of winterizing wax involves the use of ethanol. So, we often face a recurring question in the dewaxing process…

Why Use CO2 Extraction When You Use Ethanol for Winterization?

Though it is undoubtedly the cleaner extraction solvent, biomass, fatty acids, waxes and resins can be co-extracted along with the cannabidiol and other cannabinoids when CO2 is used to extract hemp. The amount that is extracted depends on the pressure of the CO2 extraction.

In general, the higher the pressure and longer the runtime, the more acids and waxes will be extracted. Low pressure CO2 extraction methods, known as subcritical CO2 extraction, produce extracts that require very little post processing.

Many companies actually skip the winterization process depending on what they are using the oils for. The trade-off for lowering the extraction pressure to subcritical is that the run time increases greatly. The flow rate must be increased to compensate for the lower run time. In the case of our extraction equipment, the flow rate increases as the pressure goes down so those customers desiring runs of critical methods are able to do so with significant efficiency.

In the case of supercritical CO2 extraction, winterizing wax is likely going to be needed. The cannabinoids and CBD oils that remain in the solution are then introduced into a falling film evaporator. The ethanol is removed from the solution and may be recycled once it has been re-conditioned and tested for reuse. The amount of ethanol that is used in the winterization process is very small compared to the amount of ethanol that is used during an ethanol extraction.

For example, one gallon of ethanol is required to fluidize one pound of hemp for ethanol extraction. 1000 lb of hemp by extension requires 1000 gallons of ethanol. In contrast, 1000 lb of hemp at 10% cannabinoid will produce approximately 100 lbs of CBD oil. 100 lb of CBD oil – Approximately 30 gallons Of CBD oil, so 180 gallons of ethanol is needed to winterize 30 gallons of CBD oil.

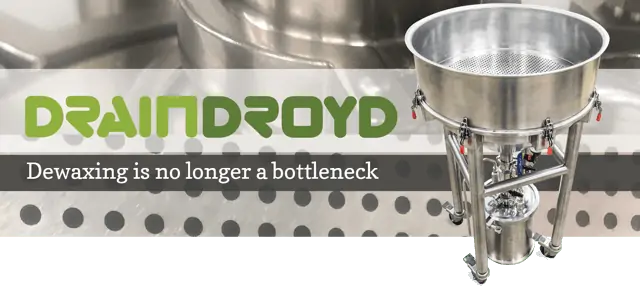

Enter the DrainDroyd filtration system

After winterization is complete, it’s time to filter out the waxes. extraktLAB’s solution to filtration, the DrainDroyd filtration system for dewaxing crude oil is a useful addition to the workflow of any hemp oil production operation.

The device is intended to not just filter solids such as waxes from fluids, but can also be used for eliminating larger solids from smaller solids such as is necessary in isolate creation or in solid phase extractions of any sort.

The basic construction of the DrainDroyd is a funnel that is wider and created from stainless steel. As it is wider and stronger than glass, the DrainDroyd can procedure 4-5 gallons of winterized oil in half an hour or less.

Filtration with traditional equipment with Buchner funnels would take much longer to produce the same result. Unsurprisingly the hemp industry is rapidly going the way of a commodity business, where the least expensive and most efficient way of manufacturing wins in the long run.

Any bottlenecks into the process, or wasted precious product, hinders a fast ROI. Whether your business is using butane, ethanol or CO2 for hemp extraction, the DrainDroyd breaks down all previous filtration barriers and offers a bottleneck solution that can allow you to attain the ROI you’ve been searching for.

When you choose DrainDroyd, you eliminate frustrating bottlenecks such as many hours of labor with small scale Buchner funnels and glass breakage. Our innovative filtration equipment also reduces the number of steps in your overall process and leads to the production of higher quality extracts.