The Future of Extraction Automation is Here

Continuous Automation Solution

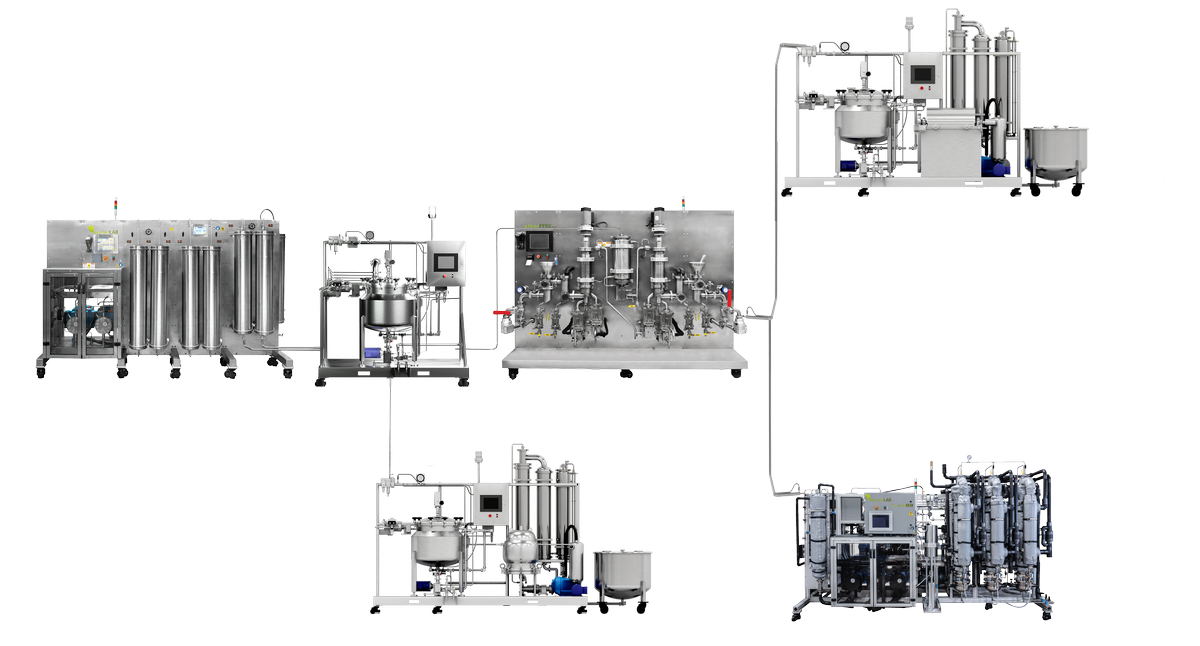

Say goodbye to tedious manual extraction and lengthy material handling processes! With Continuous Automation Solution, you can revolutionize your extraction process with the latest in automation technology. Our solution allows you to seamlessly manage from biomass to distillate and beyond; saving precious time otherwise spent on management, paperwork, or inventory.

Our innovative solution eliminates winterization, reducing labor costs, expensive solvent costs, and increasing yields of cannabinoids. With our fully automated system, you can enjoy total containment, ensuring safety and reliability – all in one simple package.

Upgrade today with The Continuous Automation Solution: where exceptional productivity meets maximum cost efficiency!

Automate Your Process, Unlock Your Potential.

Take your extraction process to the next level with the Continuous Automation solution from extraktLAB! This fully automated total containment system eliminates winterization and lowers labor costs, giving you more time to focus on what matters most–Running your business. Don’t wait, get started today!

Unlock the potential of automation for your business. Get an exclusive 1-on-1 meeting with our subject matter experts, plus resources and exclusive updates from extraktLAB when you sign up now.

Calculate Your Solution

Features

Automation

From improved efficiency and accuracy to cost savings and labor reduction, our cutting-edge technology can help you streamline the botanical extraction process.

Automation provides less variations, decreases labor, reduces downtime and increases your yield.

High Cannabinoid Recovery

Boost Processing Efficiency and Yields with our Continuous Solution. Our solution offers improved efficiency, increased yields, and higher cannabinoid recovery – delivering the ultimate competitive advantage.

Containment System

No contact, less variation, reduced contamination and completely GMP compliant. Make extraction better than ever with our fully contained extraction!

Reduced Infrastructure Requirements

Our solution gives you the opportunity to reduce hazardous solvent storage costs and free yourself from stringent regulations. Enjoy the benefits of a safe, cost-effective alternative.

Sustainable CO2 Extraction

You get a pure product without the use of expensive and toxic solvents. You’ll also save money and reduce your carbon footprint. Help us make a difference and join us in saving the planet!

Reduced Down Time and Speed to End Product

Our automated solution can help you reduce machine downtime, labor requirements, and speed up production of higher quality end products. Leveraging our advanced technology ensures you remain competitive in the marketplace.

GMP COMPLIANCE

Trust us to provide you with the most reliable and secure solution for your extraction operations. Our sophisticated technology, combined with certified components, ensures that safety is never compromised and that compliance is strictly adhered to. With this system, you can trust that you will have the highest quality extraction output every single time.

The E2Di is an interface allowing for a pharmaceutical manufacturing solution within a continuous automation solution process. These are contained systems utilizing automation of high pressure CO2 extraction through wiped film distillation. This continuous flow system promotes increased yield with a reduced cycle time. The uniquely designed interface provides oil transfer, CO2 venting, and oil metering.

This automation process eliminates ethanol and winterization, while sustaining reduced variations, contamination risk, human error, labor cost, and overhead.

Features:

Streamlined Extraction Process

No Winterization

No Ethanol

Value:

Reduced Cycle Time

Reduced Labor Costs

Benefits:

Faster Production

No Mess, Less Contact, Less Potential for Loss

Better Yield

Support

Our passionate customer service team is here for you when you need it most. Whether technical know-how or advice on which plans to choose, our experts guide you each step of the way.

Training

We understand the effort you’ve put into building your business. Let our experienced team take out the guesswork. With on-site comprehensive trainings, our experts can help your team reach success quickly and efficiently.

Get in touch with our team to request a quote and learn more about our Continuous Solution

We are dedicated to providing you with the best advice, quality and service in the industry.

Meet Our CEO and Founder Dr. Jon Thompson, Ph.D

Dr. Thompson is a separations scientist, entrepreneur, and inventor. As a scientist, he has a strong technical background and industry experience in analytical instrumentation, in-vitro diagnostics, biotech, mining, and homeland security markets. During his extraction industry career, Dr. Thompson has earned a strong track record of setting up successful startups in well-regulated industries. Dr. Thompson has assisted numerous companies to attain their goals in essential oils manufacturing, as well as market development, strategic marketing, and worldwide business-to-business alliance formation (including international markets).

He received a Bachelor of Science degree in Biochemistry, Master of Science degree in Chemistry and a Doctor of Chemistry degree–all from the University of Minnesota.