Cold Trap Terpene Collector

The terpTRAP terpene recovery module from extraktLAB is the most versatile cold trap available for terpene and vapor recovery in pre-extraction decarboxylation processes. The heat exchanger is capable of 20 tons of heat exchange capacity and process connections to support chilling, vacuum, and condensates produced by the largest decarboxylation processes. Food grade contact surfaces allow for recovery of terpenes for use in downstream formulations prior to coming in contact with ethanol or other extraction solvents.

terpTRAP: The Leading Cold Trap Terpene Recovery System

extraktLAB’s terpTRAP has innovated terpene recovery to the highest possible efficiency. This cold trap system contains a four gallon standard collection pot, 21.64 square feet of heat exchange area and can be scaled up to handle a staggering 10 ton per day processing throughput depending on biomass moisture content. These capabilities are far higher than other cold trap systems developed by competing extraction companies in the hemp and cannabis extraction industry.

How a Short Path Cold Trap Works

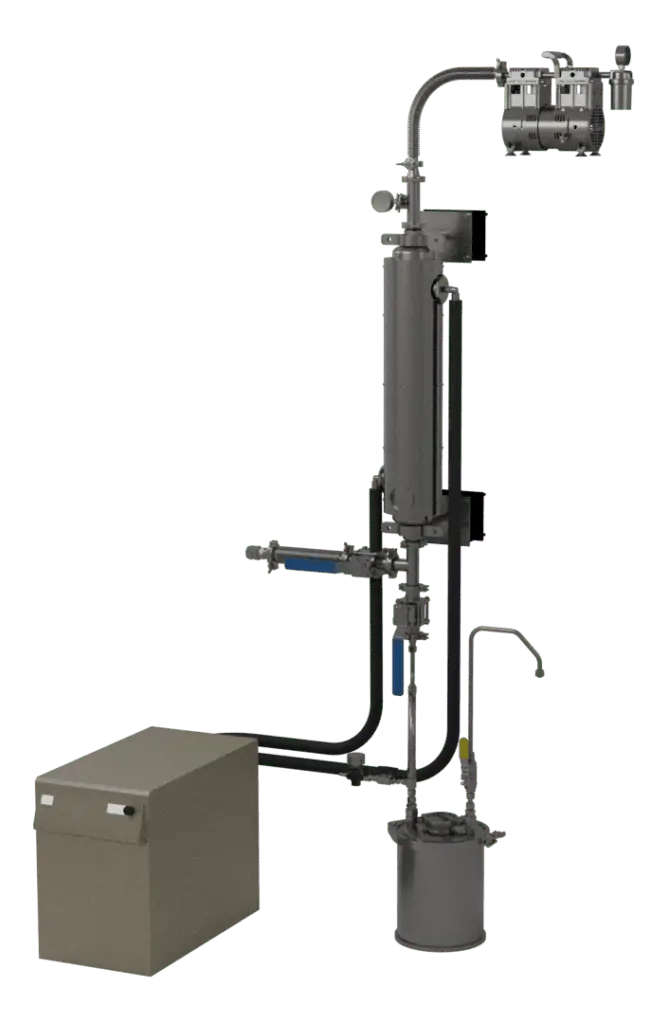

When the extraktLAB extraction method is used, decarboxylation of the biomass using vacuum ovens is performed before CO2 extraction. Not only is this a critical way to increase the efficiency of an extraction process, but it is also the key time to capture terpenes via fractional vacuum distillation. Terpenes are a very volatile compound in the hemp plant, meaning the temperature needed to evaporate them into vapor is relatively low. Because the decarboxylation process involves the use of heat and vacuum pressure, that evaporation point is low enough that valuable terpenes will be removed from the biomass. This is where the cold trap comes into play. As the terpenes evaporate from the biomass, the cold trap’s chilled collection vessel will capture the evaporated terpenes as they condense to liquid into a four gallon, food grade collection pot. These terpenes are pure, high quality, and free of any chlorophylls, waxes or other unwanted plant materials that can result from terpene collection during the extraction process. These are the best terpenes available for products formulation.

Other Terpene Related Publications

Pure Hemp Terpenes for Flavor and Aroma

The Best Methods for Extracting Hemp Terpenes

Five Hemp Compounds You Need To Know

Capture Your Own Full Spectrum Terpenes

terpTRAP’s advanced cold trap technology can provide high quality, full spectrum terpenes with little labor cost. It’s time to complete the upgrade of your terpene recovery equipment.

Are You Throwing Away Money?! Terpenes Part 1

Are You Throwing Away Money?! Terpenes Part 2

Why Terpenes Are So Valuable

The overall cost for terpenes for formulation are rather expensive generally speaking. If a producer went out to purchase wholesale terpenes for product formulation in their hemp or cannabis business, natural, full spectrum hemp terpenes would cost roughly $20-30 per gram. Because the cost for these naturally extracted terpenes is so high, many producers turn to using synthetic terpenes running roughly $10-20 per gram. These terpenes do not contain the same level of demand from the consumer as natural products hold more merit in the hemp and cannabis product industry. This makes the need for natural full spectrum terpenes all the more vital to quality product formulation in today’s competitive market. So, in truth, terpenes are highly valuable for their use and for their overall price point, but to buy them wholesale is a far costlier choice. This is why proper terpene extraction is critical for any extraction company to master, making the use of a cold trap equally as vital to collect the highest quality, natural terpenes for product formulation or wholesale.

Calculate The Boiling Point Under Pressure

Are you trying to use the Clausius-Clapeyron Equation? Check out our Calculator to Calculate the Boiling Point Under Vacuum.

Vacuum Distillation During Decarboxylation

Following the extraktLAB method, terpenes are collected in the terpTRAP during the decarboxylation process prior to extraction. This is accomplished by placing your hemp biomass into specialized vacuum ovens. Using internal vacuum pumps and specific temperature control, the terpenes are volatilized into vapor. Those vapors then leave the biomass, travel inside a short path distillation apparatus before recondensing into a liquid inside the cold trap. The method of using these vacuum ovens and temperature control short path distillation accessories result in the highest quality terpenes and terpene formulated products on the market.

While it is not entirely necessary to perform decarboxylation using vacuum ovens prior to extraction, we highly recommend it for collecting the highest quality liquid terpenes. This is where the terpTRAP’s cold trap technology shines. Using that vacuum distillation not only collects terpene vapors for high quality products, but also makes the biomass more liquid soluble, improving overall extraction as well. For this reason, we recommend the necessary accessories we use including the cold trap, vacuum ovens, pumps, temperature control and other products to perform our method properly.

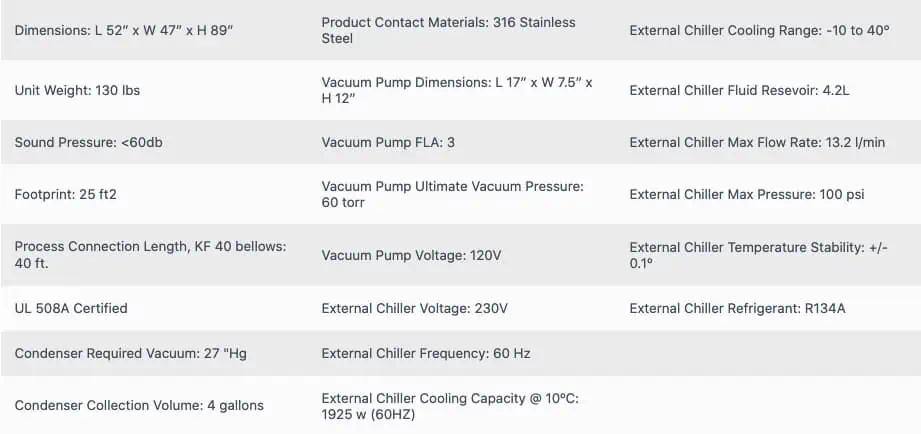

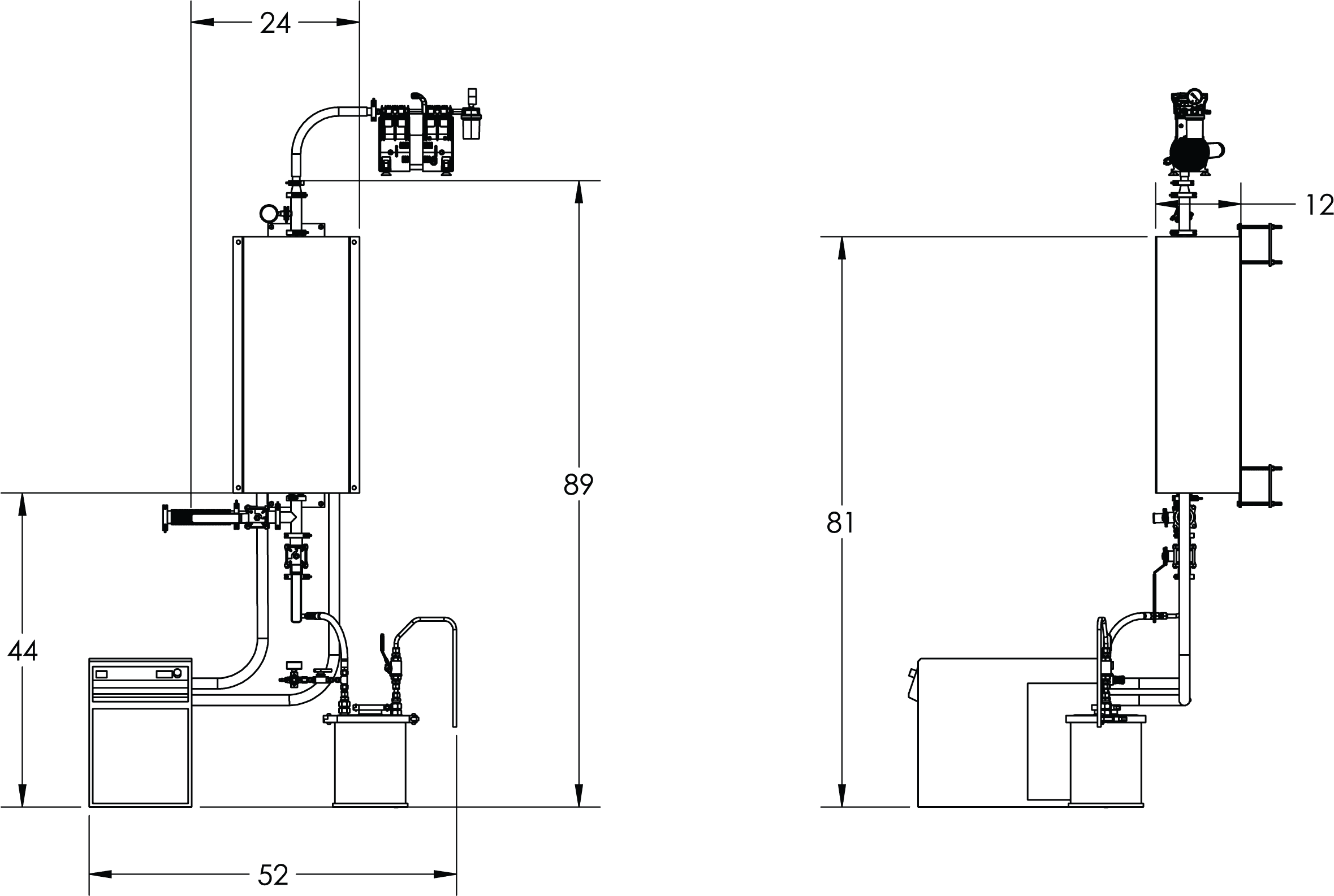

terpTRAP Specifications

Cold Trap Features and Advantages

- Designed for optimal vacuum pump protection

- Full-Spectrum terpene recovery

- GMP Compliant Product Contact Surfaces

- Scalable up to 10 tons/day (depending on biomass moisture content)

- Maximized throughput of any decarboxylation system

Testimonials

Frequently Asked Questions

How much are terpenes worth?

Synthetic terpenes are typically sold for $10-20 per gram. Full spectrum natural terpenes sell for $20-30 per gram.

What happens to the terpene profiles in CO2 extraction vs ethanol extraction?

Terpenes are extracted by both ethanol and CO2. Here are the key differences in the terpene profiles of a CO2 extracted oil versus ethanol extraction.

- Ethanol will extract most of the terpenes that are in the biomass.

- Ethanol will extract most all of the biomass cellular material, fats, waxes, and contaminants.

- In order to get the ethanol out of the extract, a falling film evaporator is used.

- Terpenes that make up the aroma (low boiling point molecules) evaporate with the ethanol.

- Terpenes that remain in the oil typically break down easily but many terpene profiles are left in the remaining oil.

- This oil is not potent, is pitch black, and really does not smell good. Distillation is typically required as a secondary purification step..

Meet Our CEO and Founder in Service Dr. Jon Thompson, Ph.D

Dr. Thompson is a separations scientist, entrepreneur, and inventor. As a scientist, he has a strong technical background and industry experience in analytical instrumentation, in-vitro diagnostics, biotech, mining, and homeland security markets. During his career, Dr. Thompson has earned a strong track record of winning and implementing medical licenses in well-regulated, medically-modeled states. Dr. Thompson has assisted numerous companies to attain their goals in and hemp manufacturing, as well as market development, strategic marketing, and worldwide business-to-business alliance formation (including international markets).

He received a Bachelor of Science degree in Biochemistry, Master of Science degree in Chemistry and a Doctor of Chemistry degree–all from the University of Minnesota.