pure99-x Preparative Chromatography

Preparative Chromatography for Cannabinoid Separation in Hemp Extract

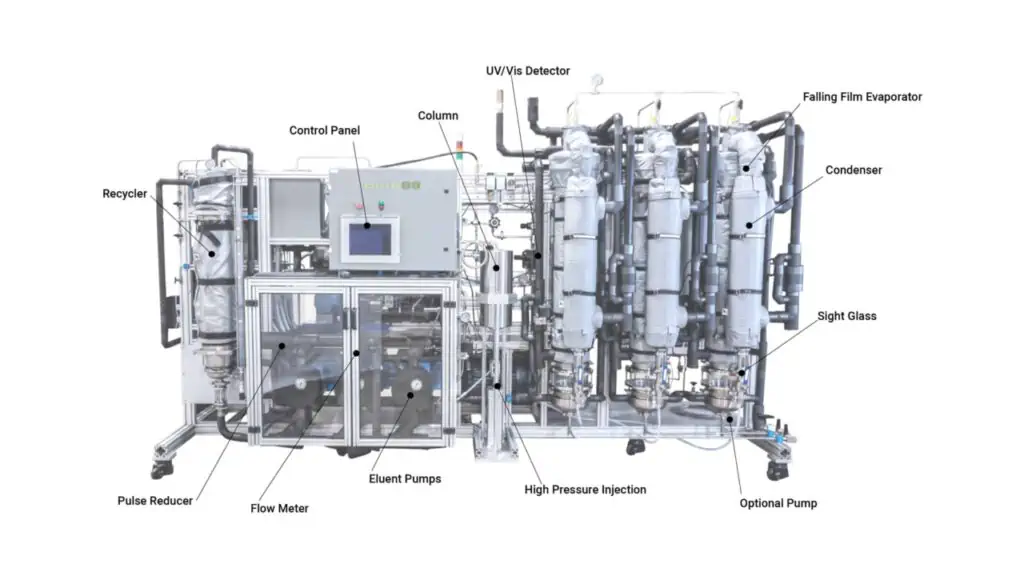

extraktLAB’s pure99 HPLC chromatography system is an automated, high-pressure liquid chromatography machine for the separation and purification of botanicals and active pharmaceutical ingredients. The chromatography machine is used to separate cannabinoids in the complex botanical matrix.

KEY APPLICATIONS

- Separation of Minor Cannabinoids

- Separation of Nutraceutical or Pharmaceutical API from Botanical Extract

- THC/CBD Remediation

- THC Isolation

Advanced Chromatography For Industrial Hemp and Cannabis Extraction

CBD Isolation

Types of Chromatography

Mobile Phase vs. Stationary Phase

Flash Chromatography

Advanced Chromatography for Botanical Separations

We have created the premier chromatography machine and method for high performance cannabinoid separations from hemp extract and the best CBD chromatography machine for separation of cannabinoids for engineered and tailored formulations.

Why pure99 for Chromatography?

- High recovery depending on cannabinoid ratios.

- Configurable production per hour (be sure to watch our video and read FAQs on production rate)

- Built in solvent recovery system enables solvent recycling on board.

- Fully automated chromatography methods enable stack injections for higher throughput.

- 21 CFR Part 11 data integrity compliance.

- Selectivity for separation of cannabinoids.

- Stable stationary phases that are low-cost.

- High pressure injection.

- GMP compliant and engineering standard compliant including C1D2 compliant, Atex II compliant, PED, ASME Section VIII DIV 2.

Read Our Other Chromatography Publications

Download Chromatography Guide

HPLC Applications

Online Product Tour

High-Performance Liquid Chromatography vs. Flash Chromatography

Water-Free Separations

One of the key issues associated with liquid-liquid extraction (CPC, CCC, LLE) is the use of water and alcohol as one of the polar phases. Simply put, water is a huge pain to remove from the resulting product. Due to the fact that water has such a high boiling point and also promotes the production of an emulsified product, water is to be avoided at all costs. Our proprietary methods enable the chromatography paper to completely avoid water in the separation thereby saving time, money, and avoiding a whole lot of hassle.

Chromatography Columns You Can Pack

The chromatography columns that we sell can be packed by the customer in less than 10 minutes. The packing material itself is a low-cost compared other proprietary packing materials such as molecularly imprinted polymeric materials.

Unlike polymeric packing materials, our stationary phase is also mechanically stable so that the column can be run at high pressure.

High Production Output

The throughput of this chromatography system depends on the column. Our largest column is 13L and will produce multiple kg of broad spectrum hemp extract per hour. The production rate depends on many different factors and your column, your method, and your sample will determine the ultimate throughput. And the throughput will vary depending on your goals. The great thing about the pure99 is that production rate also includes the solvent recovery time for the eluent that is recoverable by the chromatography system. Any solvent left in the sample will need to be recovered separately.

Chromatography Methods, Training, SOPs Included

pure99 chromatography equipment comes with built in methods that are selected for the separation of cannabinoids. As a user, you will decide how pure your extract will be and you will also decide on the recovery that you wish to obtain with this chromatography equipment. These selections and components will impact the overall throughput. You will also decide how many shifts you will have.

Stationary phase is low cost and can be packed by the customer. The material is also highly mechanically stable so the column won’t degrade or collapse at high pressure during the chromatography process.

Integrated Solvent Recycling

As with any chromatography technique that uses solvents, a huge barrier to adoption and use is dealing with all of the solvent generated as the technique is scaled up. One of the key benefits of the pure99 chromatography system is that it automatically recycles and recovers the solvent for reuse.

Solvent loss can be a key contributor to high operating costs if the solvent becomes entrained with the product during the chromatography process, however, this is not the case with the pure99. The pure99 chromatography system incorporates a falling film solvent recovery system, to avoid the hassle of having to do an extremely large amount of solvent recovery.

High Yield

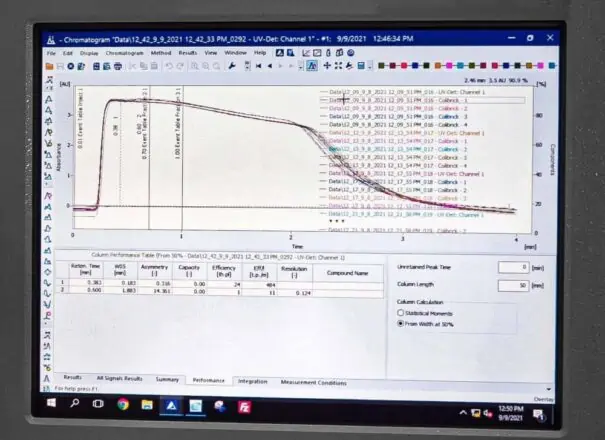

As with any chromatography method, there are always trade-offs between throughput, purity, and selectivity.

Preparative chromatography yields a very high recovery rate compared other competing chromatography techniques. For example, it is not uncommon to recover up to 99% of the target cannabinoid. Liquid-liquid techniques typically have much lower recoveries.

High recovery during chromatography depends primarily on the selectivity of separation. But it can also depend on the peak shape and operational parameters such as where the chromatographer decides to make the cuts.

Recovery largely depends on what is known in chromatography as selectivity. The greater the separation distance between cannabinoids, the greater the selectivity of the chromatography.

The separation of cannabinoids through chromatography is never perfect. In other words, recovery can also depend upon how the chromatography operator selects the psychoactive cannabinoid.

Feature Packed Chromatography for High Performance Chromatography

Equipment Specifications of the pure99 Chromatography System

- 13.6 cm high pressure liquid separation chromatography column

- Up to 24 cm column length

- High pressure gradient forming system.

- Integrated closed loop solvent falling film recovery system for ease of solvent recovery.

- Flow meter and pulse dampener for precise flow control.

- High pressure pumping system up to 2500 psi.

- Full software control, automation, chromatography methods automation, and run reporting.

- Pre pump eluent conditioner for high vapor pressure solvents.

- Reloadable media column.

| Attribute | Value |

| Separation Column Diameter | 13.6 cm |

| Separator Flow Rate Max (LPM) | 0-8 |

| Column Dynamic Axial Pressure (max psi) | 2500 |

| Eluent Inlet Lines | 2 |

| User Interface | Touch Screen 15″ |

| Automated Changeover and Sequences | Yes |

| Barcode Tracking | Yes |

| UV-Vis Detector Variable Wavelength | 210-600 nm |

pure99 Column Upgrades

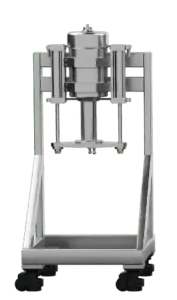

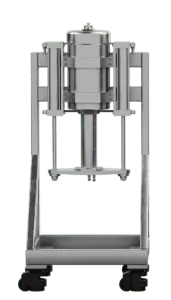

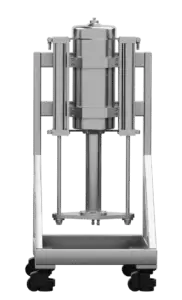

pure99 Stand Alone Columns provide separation flexibility that is required for every operation. The high maximum pressure and the variable column length allow optimization of the plate number and retention time. The unit comes as a complete assembly on casters that interfaces with the pure99 to control packed bed compression and provide eluent flow and sample injection.

Manufactured in the USA by United Science

| Dimensions | Materials: |

Inside Diameter (cm) |

Max Pressure (bar) |

Maximum Column Volume (L) |

||

130 mm ID Column (1.5L) |

316 Stainless Steel, PTFE | 13 | 172 | 1.5 | ||

140 mm ID Column (3L) |

60.96 cm x60.96 cm x132 cm | 316 Stainless Steel, PTFE, Viton | 140 | 344 | 3 | Stand Alone Column on Casters |

178 mm ID Column (7L) |

60.96 cm x60.96 cm x132 cm | 316 Stainless Steel, PTFE, Viton | 178 | 195 | 7 | Stand Alone Column on Casters |

178 mm ID Column (10L) |

60.96 cm x60.96 cm x132 cm | 316 Stainless Steel, PTFE, Viton | 178 | 195 | 10 | Stand Alone Column on Casters |

203 mm ID Column (13L) |

60.96 cm x60.96 cm x132 cm | 316 Stainless Steel, PTFE, Viton | 203 | 284 | 13 | Stand Alone Column on Casters |

Learn More About Our pure99 Chromatography Machine

Get latest specifications see if our industry leading botanical separations equipment is the best fit for your business.

What is Chromatography?

Chromatography is a separations technique that separates compounds of interest into their individual components. The combined chromatography equipment and technique is ubiquitous and is used to obtain pure compounds in nearly every industry that processes fluids.

There are many different kinds of chromatography including gas chromatography, liquid chromatography, column chromatography and thin layer chromatography. Distinct from liquid-liquid extractions, gas gas or membrane separations, chromatography uses a solid phase or stationary phase and a liquid/gas phase to accomplish the separation.

Learn more about Chromatography

Chromatography is not always the easiest topic to learn, which is why we created a course dedicated to the ins and outs of this important step in the hemp and botanical industries.

Why Use Preparative Chromatography?

Preparative chromatography is a technology used to distinguish the various compounds of a mixture and separating them into their pure components.

In the hemp and cannabis extraction industry, chromatography allows manufacturers to distinguish a list of compounds in the hemp plant and create a specifically formulated product that’s both legal and tailored to the marketplace demands.

Chromatography is also effective at identifying and removing unwanted pesticides, and other residual chemicals. These are essential factors in creating a healthy, safe, desirable product for the end user making High-Pressure Liquid Chromatography an essential part of your production.

Scalable Chromatography Solution

The issue of scalability in preparative chromatography goes hand-in-hand with liquid solvent recovery. One of the things which makes traditional flash chromatography a benchtop or lab scale technique is the quantity of liquid that is consumed. This can drive the costs of production to untenable heights.

The pure99 chromatography machine solves this liquid consumption in chromatography for a scalable solution.

With integrated closed loop technology, this chromatography equipment is designed to automatically recover excess volatile eluent.

Liquid intake is recycled back to the beginning of the chromatography column via built in inert gas counterflow distillation.

The concept of applying a fractional distillation system to chromatography technology enabled the creation of the first scalable chromatography system of its kind in the industry.

Endless Product Formulation Potential

The pure99 High-Pressure Liquid Chromatography (HPLC) system is designed to produce broad spectrum oils and purified isolates. This allows producers to keep desired cannabinoids including CBD, CBG, CBN, while removing psychoactive cannabinoids during the chromatography process.

This cannot be accomplished with a normal isolation manufacturing procedure. A very specific target removal system is required to perform this kind of specialized product formulation which pure99 chromatography is capable of.

Full-Spectrum and Broad Spectrum products have become increasingly valued by consumers in the hemp and botanical extract market, and chromatography is one of the best methods to ensure quality full and broad spectrum products.

Where normally an extraction method would be manipulated to regulate the amount of psychoactive cannabinoids in a final product formulation, pure99 chromatography allows for the producer to selectively manipulate quantities of specific terpenes and cannabinoids for specific indications tailored to the consumer’s desires.

Frequently Asked Questions

Can I separate minor cannabinoids from major cannabinoids using the Pure99 Chromatography System?

We provide methods with the Pure99 system for THC and CBD separation. We also produce selective materials for CBN separation from THC/CBD. For other minor cannabinoids, the separation depends on how it will elute from the column in relation to the other major cannabinoids in the sample. That elution time and order depends on the column separation material known as the stationary phase, and the eluent, also known as the mobile phase. Scientists who are experts at finding unique conditions that will meet the goals of the separation are called chromatographers and they do methods development to find a suitable method.

What is the throughput of the Pure99?

Chromatography throughput for the specific example of the remediation of 1-3% THC in concentrated CBD can range from 1 kg to 6 kg per hour. Similar to distillation where the throughput will depend on the purity of the sample and how aggressive the cut is made, the throughput of a chromatography system is a trade off between purity of the final product and how aggressive the “cut” is made. It really depends on you. The general rule of thumb is that the sample will be more pure as the throughput decreases.

Do you provide SOPs for the Chromatography equipment?

Yes. We provide Standard operating procedures for analytical hplc, preparative hplc, GC headspace, and for sample preparation. We also provide start up kits for each one of these pieces of equipment along with sample management software called the igwLAB

Are the Chromatography Methods Validated for Cannabinoid Separation?

The customer validates the methods according to their company’s validation protocol. Chromatography and cleaning validation protocol for analytical methods are significantly different than production validation protocol and also very significantly from customer to customer.

Do Methods Come with the Pure99?

Yes. We provide the methods for separation of THC and CBD. If the customer desires to separate out other cannabinoids, they are welcome to develop their own methods.

What other Equipment is Required for the Pure99 to Function?

Other equipment and infrastructure besides the Pure99 is required to enable the proper functioning of a separations facility. These items include equipment that is either to measure how the method is doing overtime, equipment that is needed to measure how

HPLC with methods

fracTRON to remove solvents

Headspace GC with methods

Chillers and Heaters

Stainless or Glass Mixing Tanks

Drain Droid filtration

C1D2 Compliant Room

Solvent Storage Control Area

Is Cannabinoid Separation and Chromatography Training Included?

All of our chromatography products come with 2 days of training with optional on-site training at our demo facility in Osceola Wisconsin. Cannabinoid separation methods are also provided. Additional training for HPLC and for headspace GC is typically conducted at our facility in Osceola Wisconsin. On-site training for these items may be purchased by the customer.

Does distillation replace chromatography?

Chromatography and distillation are not analogous. Chromatography utilizes differences in chemical affinity to separate a mixture of components, distillation utilizes differences in boiling points. Wiped film distillation does not separate THC and CBD despite their differences in boiling points. Chromatography will separate THC and CBD into their pure fractions.

How do you remediate psychoactive cannabinoids from CBD oils?

There are several processes for the removal of psychoactive cannabinoids from CBD distillate. These include

1. Precipitation of CBD in a solvent

2. Chromatography separations.

3. Partitioning of cannabinoids in different organic solvents.

4. Degradation of psychoactive cannabinoids with oxidation and light.

In the isolate process, the CBD is precipitated from the oil in a nonpolar solvent blend Leaving the psychoactive cannabinoid in the supernatant to be discarded.

The second process is chromatography. In chromatography, cannabinoids are separated again in a solvent while flowing A packed bed of particles. This process can be frustrating for the end-user because it requires a high level of skill to conduct the separation. Oftentimes the particles can fail and plug up if the sample that is being separated has not been properly prepared. If done correctly, this process has the potential to separate out large amounts of CBD from psychoactive cannabinoids.

The third process involves separation by partitioning between two immiscible solvents. This process is very solvent intensive and is costly from the standpoint of solvent usage. There are also issues with solvent contamination of the final broad spectrum CBD oil. If done correctly, this process has the potential to separate out large amounts of CBD from psychoactive cannabinoids.

Finally, the last process involves degrading the Delta 9 into CBN with oxidation and uv light. The problem with this approach is that the CBD also degrades so the yield for this process is typically less than desirable.

Get in touch with our team to request a quote, learn more about our training or get help with your business plan.

We are dedicated to providing you with the best advice, quality and service in the industry.

Meet Our CEO and Founder Dr. Jon Thompson, Ph.D

Dr. Thompson is a separations scientist, entrepreneur, and inventor. As a scientist, he has a strong technical background and industry experience in analytical instrumentation, in-vitro diagnostics, biotech, mining, and homeland security markets. During his extraction industry career, Dr. Thompson has earned a strong track record of winning and implementing medical licenses in well-regulated, medically-modeled states. Dr. Thompson has assisted numerous companies to attain their goals in hemp manufacturing, as well as market development, strategic marketing, and worldwide business-to-business alliance formation (including international markets).

He received a Bachelor of Science degree in Biochemistry, Master of Science degree in Chemistry and a Doctor of Chemistry degree–all from the University of Minnesota.