There is little doubt that the hemp and cannabis industry is linked to increased environmental awareness. An indication of that connection is the increased emphasis on environmentally sustainable practices that focuses on the environmental impacts of hemp and cannabis extraction. But, some extraction methods are far more detrimental than others.

This article will show you which extraction methods have the largest environmental impact, how supercritical CO2 is the most cost efficient and environmentally friendly method you can use in your operation.

Environmental Sustainability is Growing in the Extraction Industry

While the hemp and cannabis industries have always had a place in environmental consciousness, increased awareness surrounding these issues has only grown. The demand from consumers for the production of “green” products in the hemp and cannabis industry is exploding. This is why many extraction operations are doing what they can to increase their sustainable practices.

It’s true that most consumers of hemp and cannabis extract products are focused primarily on whether the end product is sustainable, but more and more of them are paying attention to the methods used to make those products. Customers will often look for organic labels, environmentally friendly certifications, and even greenhouse gas emissions (GHG) of various companies.

Not only are customers paying attention to the sustainable practices of extraction operations, government entities and investors are also paying close attention to GHG emissions and unsustainable practices in a number of processing industries. By openly integrating sustainable business practices into your operation, you are likely to open doors that will provide opportunity for investment in a multi-trillion dollar category that is increasingly popular with younger investors who are looking for these principles.

For these reasons, most extractors are keen on the way they run their operation and doing so sustainably but even the best practices can fall flat when using the wrong extraction methods. The fact of the matter is that some extraction methods are simply more detrimental to the environment than others. Some in particular are so detrimental that we feel it necessary to educate and deter processors away from them.

Now, we’ll focus on the two primary extraction methods in terms of environmental sustainability: ethanol and supercritical CO2. While one of these methods is cost efficient and environmentally friendly, the other is demonstrably damaging to the environment. On top of this, both range wildly in their operational costs. Let’s compare the costs and sustainability of these two popular extraction methods.

Ethanol vs. CO2: Which is More Sustainable?

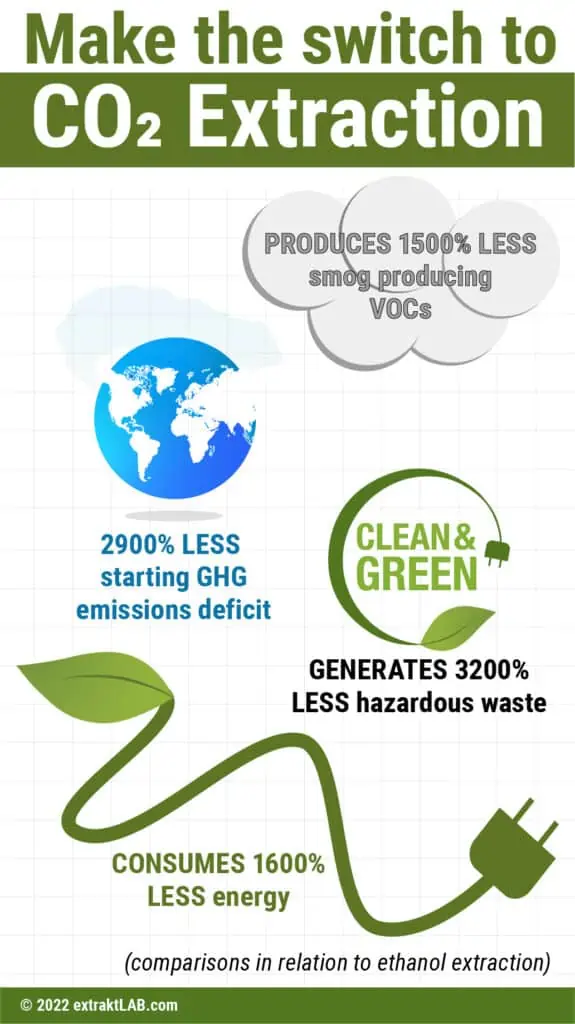

As mentioned above, environmental sustainability in this business is industry wide, but there are niches that implement these practices more efficiently. Supercritical CO2 extraction, for example, is on the forefront of environmentally sustainable practices as opposed to other extraction methods. In terms of impact, methods of extraction like ethanol and hydrocarbon are exponentially more detrimental in terms of CO2 emissions, energy use and customer health.

For example, customer interest in organic goods has drastically increased within the last decade. The ability to create safe, organic products from supercritical CO2 extraction is far more reliable than methods used to create ethanol extracted products. Denatured ethanol is a large contributor to this issue.

Chemical denaturants added to ethanol for the intention of avoiding excise tax are added intentionally to deter human consumption. But, denatured ethanol is commonly used in the extraction industry. This leads to the question of customer health after long term consumption of hemp and cannabis extracts that could otherwise be avoided using more sustainable extraction methods like supercritical CO2.

In terms of energy use, ethanol is drastically more impactful than CO2. To illustrate this, let’s take a look at a standard one-ton per day extraction facility using ethanol. This is the example size we will use throughout this article.

It is standard practice for ethanol extraction operations to use roughly one gallon of ethanol per pound of biomass extracted. At 2000 pounds, you are looking at an equivalent amount of ethanol used to extract that amount of biomass each day. Without looking further into the facts, that is already a large amount of solvent used for extraction, but it gets worse.

According to Cornell professor of Agriculture and Life Sciences, David Pimentel, it takes roughly 131,000 BTUs to make one gallon of ethanol when the energy costs of corn production and conversion to ethanol is added up. But, one gallon of ethanol is only worth about 77,000 BTU of energy value according to Pimentel’s research. This equates to 54,000 BTU lost with every gallon of ethanol made. With ethanol extraction using roughly a gallon of ethanol per pound of biomass, the energy consumed by any sizable operation is substantial.

Comparing the Environmental Footprint and Costs of CO2 and Ethanol Extraction Operations

Energy Costs of Ethanol and CO2

On top of solvent costs, ethanol is demonstrably more expensive than CO2 in terms of energy usage. The amount of energy used by ethanol extraction methods is directly associated with the method itself. This is because of the amount of solvent used during ethanol extraction and the process of heating the solvent to the point of evaporation and cooling it back down to roughly -30 degrees during each and every cycle.

For example, let’s take a look at the energy usage and costs associated with ethanol extraction against CO2 extraction. If there are 114 liters of ethanol to be evaporated each extraction cycle, it will take roughly 0.24 kwh per liter to accomplish this. At an estimated cost of $0.094, it will cost roughly $2.56 per cycle. For an average extraction operation, this equates roughly to $423.22 in energy costs every day for an ethanol extraction method.

In comparison, CO2 extraction is capable of processing around 20kg of biomass with 8.6 kwh hr. This translates to roughly 3.44 kwh per extraction cycle. At $0.094 per kwh, you’re looking at $0.32 per cycle. This means that your energy costs are just $77.61 per day under these circumstances using CO2 as your extraction method.

This also translates back into the environmental equation as well. With ethanol extraction, every 2000 lbs of biomass processed at this rate of energy usage will consume 1824 kwh which doesn’t take into account the 4408 kwh needed to cool the ethanol. With both of those figures combined, ethanol extraction takes 6232 kwh per 2000 lbs of biomass processed.

According to the U.S. Energy Information Administration, around 0.91 pounds of CO2 emissions are produced every kwh. This equates to 5671 pounds of CO2 emissions every ton of biomass processed with ethanol extraction. It’s clear that the greenhouse gas emissions from ethanol extraction are far more impactful than CO2 extraction overall.

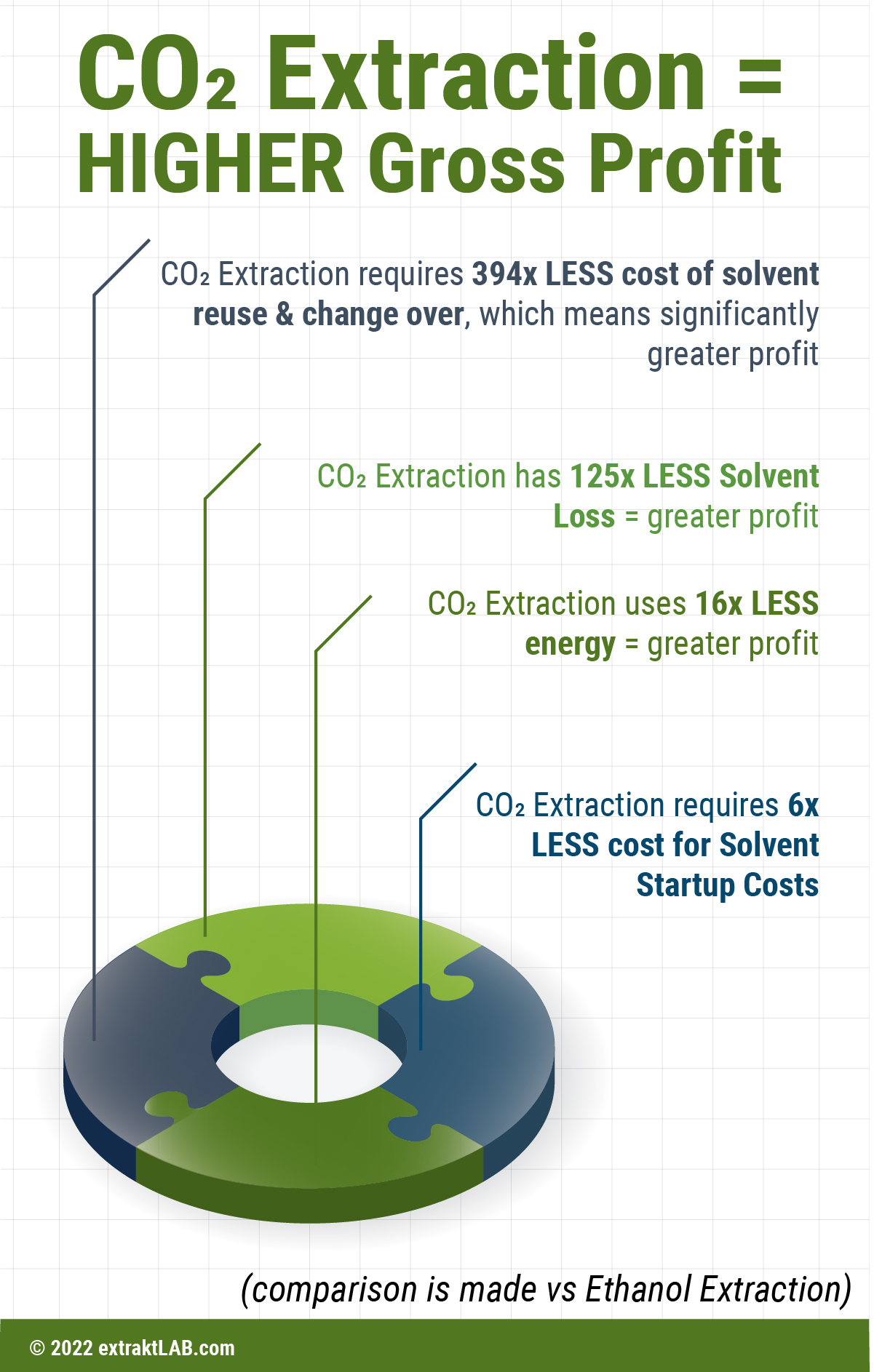

There are a number of considerations that come into play when comparing ethanol and CO2 extraction in terms of overall costs. What often stands out most to those looking to enter the extraction industry is the upfront equipment costs for each method. However, operating cost must also be considered when taking into account total cost. If you compare operating cost plus capital cost for 24 months for both co2 and ethanol, you will come to a radically different conclusion than if you just considered capital costs.

For example, Using our full-turnkey, 1-ton per day extraction system as a baseline example, the cost for CO2 equipment can be ⅓ more costly than that of ethanol due to the fact that CO2 equipment is highly specialized to handle the high pressures required to convert CO2 into the supercritical state needed for extraction. So, that must mean game over for CO2, right? Not even close.

Comparing Ethanol and CO2 Solvent Costs

Now let’s take a look at the costs associated with the solvents themselves. CO2 can be purchased for roughly $.50 to $75 per cylinder, or as low as $.04 per pound when purchased in bulk. In comparison, food grade ethanol can cost as much as $16 per gallon. Many operators try to lower this cost by using denatured ethanol. However, this is also costly and adds chemical residuals other than ethanol to the extract. So, any facility that is looking to use either of these solvent options will have drastically different startup costs right out of the gate.

Then, the issue of solvent loss comes into play. Because ethanol tends to stick to the biomass, you can never fully recover all of the initial solvent used after each extraction cycle. You can typically recover about 90% – 95% of the ethanol used where nearly all of the CO2 used during extraction can be recovered.

Because of the difference in solvent cost, the costs associated with solvent loss are drastically different with ethanol loss costing thousands per day, and CO2 in the hundreds. For example, to process 2000 lbs at $0.04 per pound of CO2 with winterization, the per day comes out to roughly $211. The same number of pounds extracted with ethanol leads to daily ethanol loss cost of 3000-8000 USD per day at 90% recovery.

Over the course of just a few years at that rate, the long-term solvent loss costs for ethanol will reach into the millions while solvent loss from CO2 will be two to three times less expensive. This is the primary operating cost factor that makes ethanol much more costly than CO2.

Environmental Sustainability Calculator

Use this calculator to find some of the main components contributing to your carbon footprint.

Final Thoughts on the Benefits of CO2 Extraction

It’s clear that a focus on sustainability is ramping up in the extraction industry. So, it’s important to implement environmentally sustainable practices into your process while maintaining a profitable business. Hopefully this clarifies both the cost effectiveness and the environmental impact of supercritical CO2 when compared to ethanol extraction.

It is common for new or aspiring extractors to look at the lower startup equipment cost, ease of use and availability of ethanol extraction and jump on it as the best option for them. But, as we’ve illustrated, CO2 extraction is much more beneficial in the long run both in environmental impact and reduced operational costs when optimized correctly.

If you take these factors into account, you can make the right moves to remain profitable and sustainable in a fast growing industry that is leaning towards all things sustainability. If you are looking to enter the business of extraction, or improve your craft toward the trend of sustainability, be sure to reach out to an industry expert who has your interests in mind, and do your research to find the best solution for you. These trends are soon to be cemented into the world of hemp and cannabis extraction. Don’t get left behind by missing out on the opportunities of CO2 extraction