The following article explains the key differences between short path and wiped film distillation equipment and techniques. We discuss the operation of the equipment and also compare and contrast some key distillation operating parameters.

For years, the hemp extraction industry has used two common distillation processes known in the market as short path distillation (SPD) and wiped film distillation (WFD). To create a quality hemp distillate, short path and WFD equipment have become standard practice in the hemp industry and are both essential to the manufacturing process. But, what are the differences between the two and what advantages does each method have to offer producers?

Short Path Distillation and Other Distillation Processes

Distillation is a significant component of any hemp or CBD processing business. The process of distillation varies, depending on the type. The general definition involves an application of heat, changing the hemp substance from a vaporized to a liquid state, and elements separating. In terms of CBD distillation, purifying a thicker substance by way of solvent or other degradation means it produces a potent hemp product.

There are two primary distillation processes in the CBD industry that are commonly known in the market as short path distillation (SPD) and wiped film distillation (WFD). To create a quality hemp distillate, short path and wiped film equipment have become standard practice in the hemp industry and are both essential to the manufacturing process.

Short Path Distillation Process

The short path distillation definition is a technique that encompasses a distillate (an already separated product by way of chemical application) traveling a short distance at a greatly reduced pressure.

The short path distillation procedure does not use solvents like other methods, as it instead uses a built-in heating system to melt cannabinoid elements for separation purposes. Utilizing its compact system, following the short path distillation guide will involve gradually increasing the heat of a flask.

While this heat rises, hemp material is being added in and a vacuum reduces the vapors to extract the necessary biomass. Then, a fractionating tube links up with a condensing tube to separate elements, while shaping them into the proper matter and form for that particular product.

The amount of weight and initial hemp material added will affect how much the short path distillation yields.

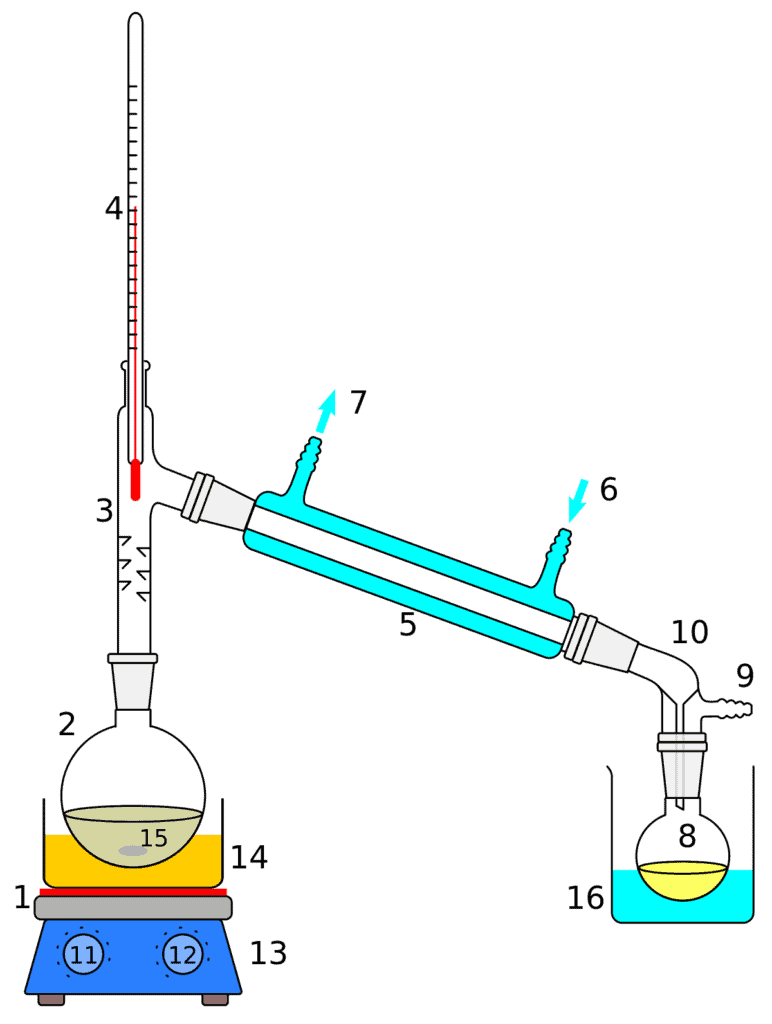

To achieve the desired distilled CBD oil product, a typical short path distillation setup uses a round bottom flask, heating mantle, and chilled condenser to evaporate and collect volatile fluids as shown in Figure 1.

Winterized and decarboxylated CBD oil is introduced to the round bottom flask which is then heated by the heating mantle to vaporize volatile components from the remaining liquids. Once evaporated, the vaporized components are collected on the chilled condenser.

“In the case of fractional distillation, no film is made by the apparatus and ‘starve feeding’ the short path can greatly improve efficiency with the tradeoff of reduced throughput.” – Dr. Jon Thompson

The residence time that the oil spends exposed to high heat is on the order of 10-60 minutes. This makes short path equipment best for samples that do not degrade easily or for low viscosity mixtures that are capable of boiling at a lower overall temperature.

This equipment can also be used for short path fractional distillation when multiple receivers are used.

The short path distillation diagram reveals that this method will allow for the extraction and separation into different factions of cannabinoids, terpenes, and solvents. If you are having difficulties with the machine or have trouble following the short path distillation process explained above, ask for a live demo.

Benefits of Short Path Distillation

The advantages of short path distillation are numerous for both consumers and producers.

Short path distillation has a valuable feature called “continuous feed” that other distillation processes may not be able to offer.

Essentially, the component involves a highly accurate evaporation system that requires fewer high temperatures to extract the same amount of quality hemp product.

Thus, more material can be extracted so more biomass may be produced.“Continuous-feed” also allows for potent hemp and CBD products to be produced without the archaic use of a heated beaker or solvents. Without the use of solvents, a purer hemp extract will be generated.

The THC is at a 99% potency rate for CBD products created using the short path distillation method.

Short path distillation is also fairly compact when compared to other distillation processes. It has an automated processing system, making it user-friendly and accessible.

Components of Short Path Distillation

Chiller

The temperature can vary from anywhere between 212F to 482F when using short path distillation. The chiller component of this process is not necessarily used for freezing or cooling for solidification purposes, but to keep the overall temperature of the entire process at 122F. The specific temperature of 122F will prevent hemp elements from getting clogged during short path distillation, as it will allow for more vapors to become compacted.

Cold Trap and Vacuum Pump

The cold trap works with the chiller to prevent vapors from dispersing and escaping. If the vapors leave the condensing chamber, they may cause damage to the vacuuming system. Utilize this component to extend the lifespan and reduce the maintenance cost of your vacuum pump.

The vacuum pump allows for the oil or CBD extraction elements to flow through it.

There are different types of pumps, but the one most recommended is the rotary vane pump. This type of vacuum pump has the most depth and expansion, which lets the producer collect a maximum amount of hemp product. Increased profits are a likely outcome of using the rotary vane pump.

Vacuum pumps go through an excessive amount of wear and tear, due to chemical processing, so be sure to change the oil often.

Short-Path

The short path feature of the short path distillation process includes four glass elements. The heating mantle consists of the following.

- Boiling flask – used to raise temperatures to a boiling point level

- Short path head – connects cooling lines to the vacuum system

- Receiving cow – condensers to catch the distillate

- Receiving flasks – there are three in total (single cow flasks, changeable adapters, and head packing) collects hemp product

The heating mantle is how the extraction coalescence reaches boiling point. The heat will then cause vapors to cling to tiny formations within the mantle. The formations will create a sort of “groove” for future purification purposes.

A condenser is also an integral part of the short path. The condenser is used to solidify the vapors into color. Get machine specifications to obtain your short path distillation processing components today.

Hemp products may run through the short path distillation process multiple times. This is advantageous to producers because the processing time is so short. Thus, a pure, potent product will be yielded in a short amount of time.

Short Path Distillation Vs Wiped Film Distillation

Short path and wiped film are both single-stage, simple distillations. Their methods, processing durations, product yield, and cost differ.

Wiped Film Distillation

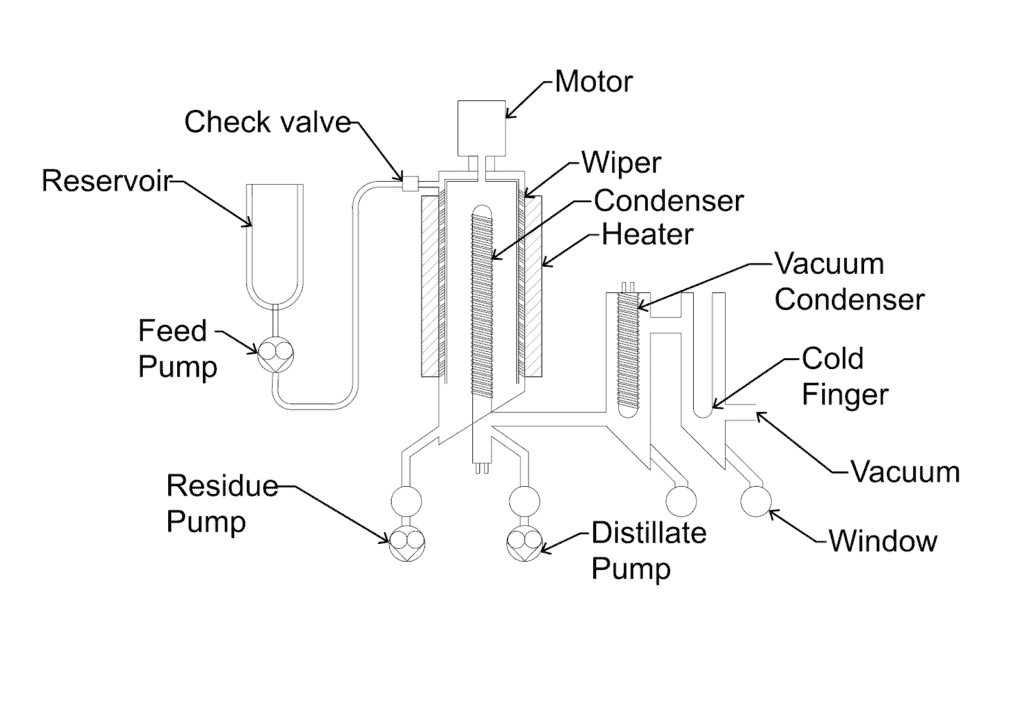

In the case of wiped film distillation, the distillation machine produces a film of oil on a hot surface with wiper blades as seen in Figure 2. WFD equipment uses mechanical wipers within the machinery to produce the film. This allows for liquids with a higher viscosity and higher boiling points to be distilled and reduce the time spent on a heat source before evaporation.

Components in the oil evaporate and travel to a nearby condenser and condense on that surface. The wiper is highly engineered to provide a thin film at the evaporator surface that is mixed at the surface as well. This mixing improves mass transfer and the efficiency of the separation.

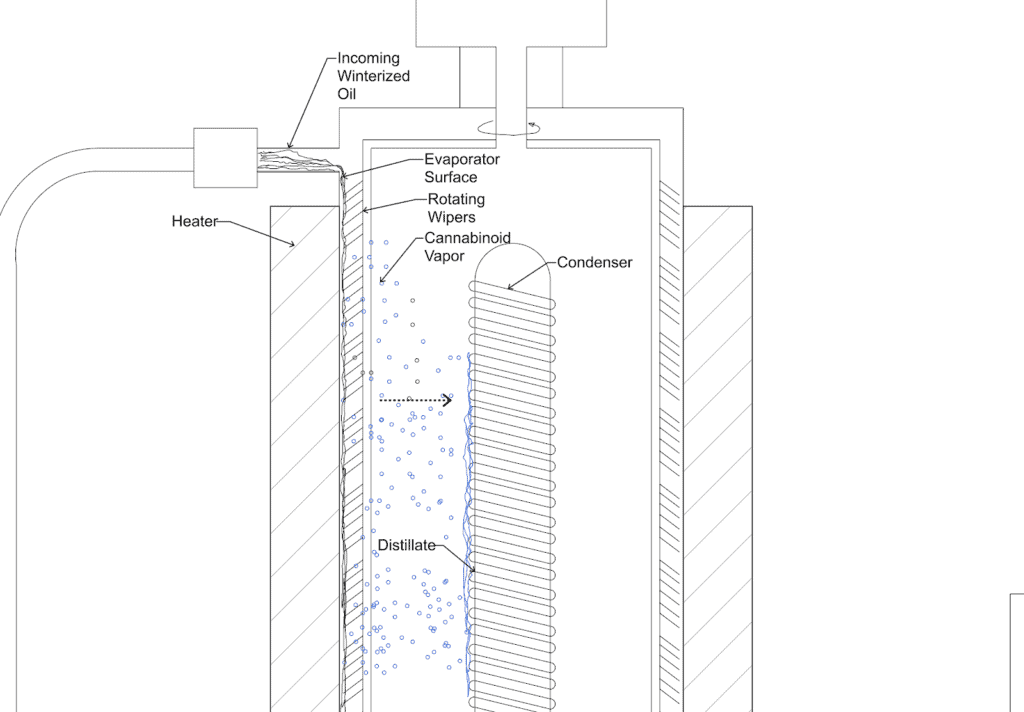

As seen in Figure 3., the heated reservoir holds the winterized decarboxylated oil that feeds the still. The feed is pumped through the feed pump and enters the still under high vacuum pressure.

Conditioned vacuum pressure is provided by a mix of roughing vacuum pumps and optional turbo molecular pumps. Cold fingers and vacuum condensers are typically installed in between the vacuum and the still to condense volatile molecules in the vacuum so that a high vacuum gradient exists between the still and the vacuum source.

As the wipers rotate, the oil is spread onto the evaporator wall. The wipers continue to mix the fluid as it moves down the column.

The operator may desire either the residue or the condensate (distillate). So, different methods can be run to optimize the recovery of either. Some of those compounds will not condense on the condenser and therefore will diffuse through the vacuum and condense on the “cold finger” that is installed just before the vacuum.

When there is an excessive amount of solvent in the oil to be distilled, a pre-processing step may be required.

Short Path Distillation vs Wiped Film Distillation – Drawbacks and Advantages Compared

The residence time that the oil spends exposed to high heat for short path distillation is on the order of 10-60 minutes compared to wiped film distillation at 1-3 minutes. This means that the terpenes, solvents, and cannabinoids can be separated into different fractions using this equipment. This is something that cannot be done on a WFD apparatus.

So, although the duration of the short path is longer when compared to wiped film, the product yielded will be of much higher quality. Therefore, more profit may be generated from a single process.

Some short path vacuum distillation equipment relies on mechanical means to create a film for efficient evaporation. For example, a rotary evaporator uses a rotating round bottom flask to create a film on the glass walls. A falling film evaporator performs a similar function that uses gravity to create an evaporative film that runs down the heated column.

The cost of wiped film distillation parts can run from anywhere between $5,000-$40,000. While the price of short path distillation components typically ranges from $3,000-$10,000, depending on capacity levels.

Producers may find a short path fractional distillation kit to be simpler, have a smaller footprint, and the equipment certainly comes with a smaller price tag. For these reasons, many producers turn to a short path as a standard route for distilling hemp extraction solvents.

Short path distillation is a more cost-effective method that generates a higher quality CBD product. Table 1. summarizes the discussion and will help guide your decision as to when to deploy each method but talk to an expert to fully comprehend the wide variety of benefits to the short path distillation kit from extraktLab.

How Does Short Path Distillation Work?

In order to achieve the desired distilled CBD oil product, a typical short path distillation machine uses a round bottom flask, heating mantle, and chilled condenser to evaporate and collect volatile fluids as shown in Figure 1. Winterized and decarboxylated CBD oil is introduced to the round bottom flask which is then heated by the heating mantle to vaporize volatile components from the remaining liquids. Once evaporated, the vaporized components are collected on the chilled condenser.

Components of A Typical Short Path Distillation Equipment

Figure 1

The components of a Short path distillation machine in Figure 1 are:

- Heat source,

- Round bottom flask,

- Still head,

- Thermometer,

- Condenser,

- Cooling water in,

- Cooling water out,

- Receiving flask,

- Vacuum Inlet,

- Still receiver,

- Heat control,

- Stirrer speed control,

- Heat source,

- Heating bath,

- Stirrer,

- Cooling bath

“In the case of fractional distillation, no film is made by the apparatus and ‘starve feeding’ the short path can greatly improve efficiency with the tradeoff of reduced throughput.” – Dr. Jon Thompson

The residence time the oil spends exposed to high heat is on the order of 10-60 minutes compared to WFD at 1-3 minutes. This makes short path equipment best for samples that do not degrade easily or for low viscosity mixtures that are capable of boiling at a lower overall temperature.

This equipment can also be used for short path fractional distillation when multiple receivers are used. This means that the terpenes, solvents, and cannabinoids can be separated into different fractions using this equipment. This is something that can not be done on a WFD apparatus. Even though fractionation may sound good in theory, it is difficult to achieve due to overlap of boiling points and eutectics in practice.

Producers may find a short path distillation kit to be simpler, have a smaller footprint, and the equipment certainly comes with a smaller price tag. For these reasons, many producers turn to a short path as a standard route for distilling hemp extraction solvents.

Short Path Distillation Benefits

A short path distillation process is crucial to create a distillate that is highly potent and flavorful for the end user. While unrefined hemp products are undoubtedly popular, the purity of distillates as high as 99% are only increasing in demand making them and short path distillation, a necessity for any hemp extraction business to include in their product lineup.

In terms of benefitting the producer, there are many short path distillation solutions that contribute to scalability and overall throughput increase. Fully automated short path distillation equipment that is capable of continuous feed processing allows for high quantity distillate production while maintaining purity, potency and consistency that is ideal for ideal distillate products in a competitive industry.

Basic Description of Wiped Film Distillation

Some short path vacuum distillation equipment relies on mechanical means to create a film for efficient evaporation. For example, a rotary evaporator uses a rotating round bottom flask to create a film on the glass walls. A falling film evaporator performs a similar function that uses gravity to create an evaporative film that runs down the heated column.

WFD equipment on the other hand uses mechanical wipers within the machinery to produce the film. This allows for liquids with a higher viscosity and higher boiling points to be distilled and reduce the time spent on a heat source before evaporation.

In the case of WFD, the distillation machine produces a film of oil on a hot surface with wiper blades as seen in Figure 2. Components in the oil evaporate and travel to a nearby condenser and condense on that surface. The wiper is highly engineered to provide a thin film at the evaporator surface that is mixed at the surface as well. This mixing improves mass transfer and efficiency of the separation.

Figure 2.

Components of the Wiped Film Distillation Machine

- Check Valve

- Reservoir

- Feed Pump

- Residue Pump

- Motor

- Wiper

- Condenser

- Heater

- Vacuum Condenser

- Cold Finger

- Vacuum

- Window

- Distillate Pump

Separation in this format makes for a much more efficient way to achieve a higher evaporation rate of the desired product. The thinner the film gets, the more efficiently cannabinoids and terpenes can be evaporated and collected on a chilled condensation surface.

WFD is often done in two passes per cycle. One pass removes trace components like remaining terpenes, chlorophyll and other plant materials. The remaining mixture would then be re-run through with minor changes in temperature and pressure in the second pass to refine desired cannabinoids like CBD.

Because of this, the WFD process generally creates a higher resolution, increases potency, and creates a consistent distillate for production. Let’s take an even closer look at how a WFD apparatus works.

A Deeper Look at Wiped Film Distillation

As seen in Figure 3., the heated reservoir holds the winterized decarboxylated oil that feeds the still. The feed is pumped through the feed pump and enters the still under high vacuum pressure.

Conditioned vacuum pressure is provided by a mix of roughing vacuum pumps and optional turbo molecular pumps. Cold fingers and vacuum condensers are typically installed in between the vacuum and the still to condense volatile molecules in the vacuum so that a high vacuum gradient exists between the still and the vacuum source.

As the wipers rotate, the oil is spread onto the evaporator wall. The wipers continue to mix the fluid as it moves down the column.

As the liquid is heated, the volatile components begin to evaporate from the evaporator surface (blue bubbles). Once in the gas phase, they randomly migrate through the vacuum to the condenser. Since the condenser is cool, the molecules condense back into a liquid. As the condensate accumulates, it starts to move down the finger by gravity and exits the still via the distillate pump.

Figure 3.

The residue on the other hand does not evaporate and continues to be pushed down the evaporator wall by the wipers. It exits the still via the residue gear pump. Thus, the distillate and residue are separated.

The operator may desire either the residue or the condensate (distillate). So, different methods can be run to optimize the recovery of either.

In the case where there is solvent in the oil or low boiling compounds such as terpenes, the vacuum in the still will be limited by the vapor pressure of components that are being evaporated. Some of those compounds will not condense on the condenser and therefore will diffuse through the vacuum and condense on the “cold finger” that is installed just before the vacuum.

When there is an excessive amount of solvent in the oil to be distilled, a pre-processing step may be required. This is where a wiped film evaporator “WFE” or a falling film evaporator may be most optimal.

Comparison of The Two Distillation Techniques

In summary, short path fractional distillation is quite different from WFD based on the above conversation. Table 1. summarizes the discussion and will help guide you decision as to when to deploy each method.

Table 1.

| Distillation Comparison | Short Path (fractional distillation) | WFD |

| Mean free path¹ | Long-6-10” | Short – 1-2” |

| Mixing | Stir bar | Wiper blades |

| Residence time for distillation² | 5-60 min | Short 1-2 min |

| Changeover Time | 20 min | N/A, continuous |

| Film Thickness | No “thin film” is made | 1-5 mm typically |

| Typical Vacuum Level | 0.1 torr | <0.001 torr |

| Fractionation | Yes | No, unless incorporated with external equipment. |

- The distance a molecule needs to diffuse in the gas phase to reach the condenser.

- Typical residence time for oil to complete a process.

Basic Distillation Setup (Not Recommended)

The short path distillation apparatus is composed of many individual components. As such, the setup can be a bit of a challenge which is why we recommend molecular still or wiped film distillation.

To help you understand this process, here are step-by-step instructions for a simple distillation setup:

- Begin with a round-bottom flask. This is the most crucial piece of glassware because it holds the liquid to be distilled. Because it contains possible dangerous and hazardous chemicals, you’ll want to properly set it up, with a small three-pronged clamp, two ring stands, and a ring clamp.

- Place the ring clamp on the ring stand to hold the heat source. You can use either a steam bath, hot plate, or heating mantle.

- Above the ring clamp, secure the round-bottom flask to the ring stand using a three-pronged clamp. It is important to tightly secure the flask since it will hold the distilled liquid. The next item to be added is the Y-adaptor.

- The Y-adaptor sits on top of the round-bottom flask. Then, a condenser secures the Y-adaptor to the system using a Keck clip and versatile clamp.

- Connect the vacuum adaptor to the condenser using a Keck clip. Secure the condenser to the ring stand with the versatile clamp. Add a couple of boiling chips into the round-bottom flask through the Y-adaptor.

- Place a stemmed funnel on top of the Y-adaptor and pour the liquid you want to distill through it so that it goes into the round-bottom flask with a boiling chip. The flask should be between ½ full and ⅔ full.

- Depending on the type of distillation you are completing, place an Erlenmeyer flask, beaker, vial, or graduated cylinder under the vacuum adaptor. This is the receiving flask.

- At the top of the Y-adaptor, connect a thermometer adapter and thermometer to help measure the boiling point of the liquid. A thermometer is usually added last because it is susceptible to breakage.

- Connect two pieces of Tygon to the condenser. The tubing to the lower connection goes to the water source, while the upper connection goes to the drain.

- Make sure all the glasses and tubing joints are secured before turning on the turning water and steam.

- Begin heating the liquid in the round-bottom flask to start the distillation process.

extrakLAB is an innovator in hemp distillation equipment. The introduction of the clearSTILL 400 changes the world of WFD offering continuous, two-stage distillation and 4-6L/hour throughput capacity that greatly increases production and lowers labor costs. Want to learn more? Contact us at: 651-600-0036