This article illustrates the numerous features and benefits of extraktLAB’s igwLAB- a Manufacturing Execution and Quality Tracking System (MES) tailor made for the hemp manufacturing industry

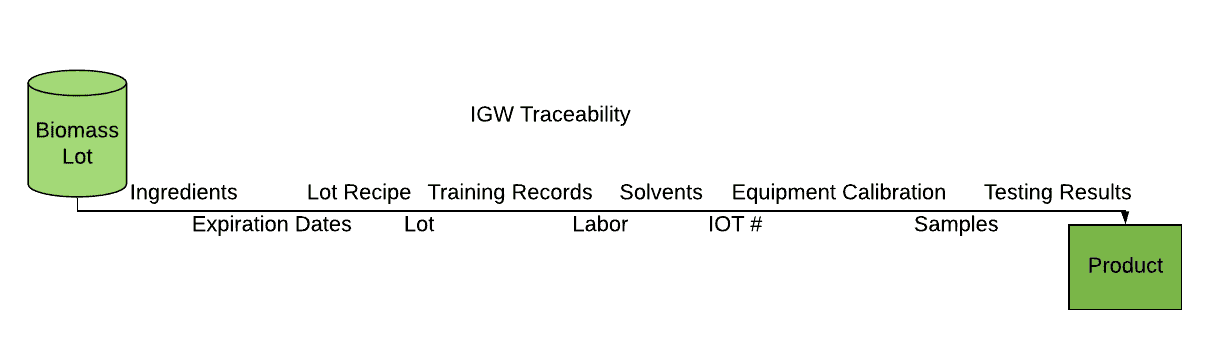

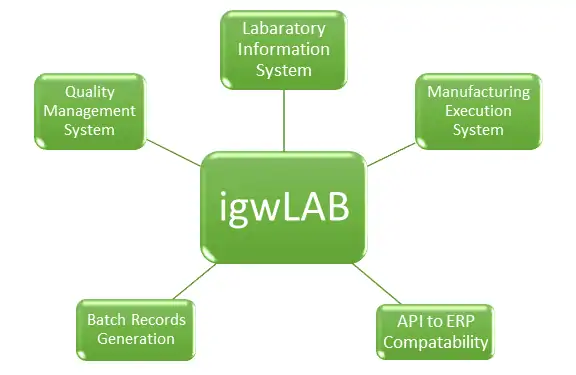

From receiving and extracting biomass to packaging a final product, a hemp processing company’s execution, quality management system and biomass tracking system must be streamlined. Enterprise Resource Planning software (ERP) is typically employed in a manufacturing setting to record and track hemp and CBD oil inventory. However, ERP systems often rely on the Internet of Things (IOT). extrakLAB saw the gaps related to integration and management of these manufacturing systems and created the igwLAB – a specialized tracking and manufacturing execution system (MES) designed for the botanical extraction industry. The software is designed to aid managers, cost accountants and to work seamlessly with a company’s ERP systems.

To discuss the benefits of igwLAB, we sat down with extraktLAB’s Applications Chemist, Cole Holstrom, and asked how this system can be used, who can use it, and why it streamlines a hemp extraction process through an entire production.

“igwLAB is for anybody who wants to monitor a complex manufacturing process and keep visibility on key processes,” says Holstrom. “IGW is a manufacturing execution software that interfaces with an existing ERP. With a traditional ERP system, however, you are capable of managing inventory and issuing work orders, but you would not have visibility of how those orders are actually executed. So, what the igwLAB will do is monitor the changes in the product throughout each step of the production process to provide critical business data to management.”

13 Hemp Processing Control Modules

In order to monitor the production process step by step, igwLAB has 13 process control modules that include:

The igwLAB is a hardware/software combination containing: Stainless steel workbench, computer, adjustable arm mounted display, bar code scanner and printer, arm mounted scale reader, scale and IGW software.

- Receiving of raw material

- Bucking and grinding hemp

- Sampling for contaminants

- Extraction

- Decarboxylation

- Dewaxing

- Isolation

- Distillation of CBD plant extracts

- Formulation of extracts

- Filing and packaging of products

- Product shipping

- Overall analysis.

“In any manufacturing process of a complex product, you want to be able to identify throughput yields and efficiency at each stage,” says Holstrom. You also want to be able to see if there is a bottleneck at a certain point so you can allocate more resources, or equipment at that point in production. It’s also important to generate reports after the fact to ensure that you are maintaining a certain level of quality through yields and throughput throughout the process.”

Integrated Reports “Out of the Box”

igwLAB is fully integrated with 11 standardized reports designed to make reporting on the manufacturing processes easy:

- Equipment list by S/N

The igwLAB dashboard is a simple to use tool for streamlined operations reporting for any manufacturer to implement

- Pass/Fail by lot, by vendor

- Lot List

- Expiration Date

- Equipment Actions list

- Equipment Overdue Actions

- Received Lots

- Orders Shipped to Customer

- Lot Progress

- Mass Per Location

- Yield Report

“The last three reports are especially useful to manage your overall process as they tell you how mass is efficiently (or inefficiently) moving through your manufacturing process, tell you where your mass is at any one time, and if your processes are behaving within historic ranges,” says Holstrom. “Furthermore, the database can be integrated by someone with relevant experience. For example, someone who knows Microsoft PowerBI can access the database via the IGW’s API and make whatever custom reports they want.”

Optimizing Hemp Processing Workflow with igwLAB

Not only will igwLAB provide insight into the entire production line, it will also allow for optimization of throughput during the CO2 extraction process, customer and regulatory reporting and even record employee productivity among many other features.

Accuracy and productivity are crucial to optimize production on the factory floor from start to finish. To do that, the MES system focuses on precision tracking and ease of use for operators and producers.

“What’s nice about IGW is that it’s very simple for the operators,” Holstrom says. “If you try to gather data in your process and it’s not simple, your operators are not going to want to use it. Many people complain about endless paperwork, lots of clipboards, and things quickly scribbled down that are illegible. igwLAB eliminates the paper trail and makes ease of use a priority for operators.”

Standard Operating Procedures Included

Anyone involved in any MES or software implementation know that the process is not very pleasant. As mentioned before, extraktLAB has taken the initiative to integrate key management systems with the botanical extraction industry in mind. By doing so, igwLAB is built by hemp producers, for hemp producers. That being said, the software itself is incredibly adaptive and is capable of working with systems outside of extraktLAB’s production line and even outside the industry altogether.

“igwLAB was designed specifically with the hemp industry in mind to provide features that other generic software adapted from that other industries really didn’t cover,” says Holstrom.

“The igwLAB is tailored to take into account extraktLAB’s processes and methodology and seamlessly integrate quality, MES ERP, and laboratory information. We provide all key SOP process documents so that there is a very minimal amount of modification and setup.”

“With only a slight modification, you could apply igwLAB to any type of manufacturing process. Let’s say your company makes sausage for example. You want to have raw inputs, making sure that it’s being ground up at a certain point, that it’s being mixed to a certain degree, that it’s passing through ovens at a consistent temperature, etc. So, you really can apply it to a variety of different industries and processes.”

For any manufacturer, igwLAB is capable tracing the entire production line. This allows producers to access product line records from point A to point B and every step in between. Doing this ensures that productivity of any production process can be monitored, recorded and carefully analyzed for optimization of the entire process.

Simplicity Equals Productivity

What about installation? igwLAB is a specialized software, that must mean a complicated installation to get started. Luckily, nothing could be further from the truth. With a cloud software platform and programmers only a phone call away, getting started with igwLAB is uncomplicated. The software comes prefigured with extraktLAB’s equipment, workflow, work instructions and SOPs.

“Installing the igwLAB is incredibly simple,” says Holstrom. “The software is all cloud based, so in the initial setup, the equipment comes with the software already installed and you simply put it in place. There are some short phone calls with the programmer to set up the account and operators and training consists of showing administrators the flexibility of the settings. After that it’s simply up to the customer to apply it how they wish.”

Interested in streamlining your entire production with igwLAB? Give us a call at 651-600-0036 for more information.

REFERENCES:

- “CFR – Code of Federal Regulations Title 21 – FDA.” CFR – Code of Federal Regulations Title 21. Accessed 17 Mar. 2020.

- “Governance | European Food Safety Authority – EFSA ….” Governance | European Food Safety Authority. Accessed 31 Mar. 2020.

- “European Medicines Agency – Europa EU.” European Medicines Agency |. Accessed 18 Mar. 2020