CBD distillate is the key to making quality CBD based products. The following article dives into several prominent trends in the world of hemp distillation and the key to making quality CBD distillate including GMP compliance, reduced maintenance, full automation and more. It highlights extrakLAB’s latest distillation technology in the fracTron 1000 and clearSTILL 400.

Distillation is not a new technology by any means, but advances in the industrial hemp extraction industry are appearing in strides. From essential oils, to spirits, to making CBD distillate, the distillation process is critical to create a pure, refined product. So, what developments have been made in hemp oil processing equipment, and how do those developments affect the hemp extraction industry?

What Is CBD Distillate?

CBD distillate is a viscous, fluid-like product that is extracted from the hemp plant. The term “distillate” is used because the product is made via the distillation process. This process uses heat, vacuum pressure and thin film evaporation to remove all other impurities, water, etc. to leave a distillate that is in the 90%+ CBD purity range.

CBD distillate can have many variations. For example, a full spectrum distillate may have a full range of cannabinoids, including legal levels of THC, along with terpenes, flavonoids and other plant compounds. Another form of CBD distillate is broad spectrum. While very similar to full spectrum, broad spectrum CBD distillate will have a broad range of cannabinoids and other plant compounds, but will specifically have the delta 9 THC removed.

Then, there is isolate, or THC-ND CBD distillate. This distillate is intentionally processed so that it is nearly 100% pure CBD with no other cannabinoids or plant compounds. The process to make this kind of distillate is more refined, and is specially formulated and tested to ensure that it is as pure and safe as possible.

All forms of CBD distillate have their place in the market. Depending on the customers desires, full spectrum, broad spectrum and isolate can be important to them where other products are not usable for them. Therefore, it is important to incorporate all of them in your process.

The reason for this is that delta 9 THC is not federally legal and has psychoactive properties. Both of these properties give reason for some users of CBD distillate to use one product over another. For example, if a customer has an issue with psychoactive products and doesn’t want to risk any form of adverse effects, they may find that a broad spectrum or isolate product is best for them.

On the other hand, the full range of cannabinoids in a full spectrum distillate may have beneficial effects for someone who can take delta 9 THC without issue. This is referred to as The entourage effect. This effect means that cannabinoids, terpenes and other plant compounds work better in conjunction with one another than separately. If a customer has no problem taking THC in small amounts, then a full spectrum product may be the best option for them.

CBD Distillation: Equipment, Processes and Output

CBD distillation is a fascinating process that makes the products that users of CBD and THC products know and love. This includes vaporizers, tinctures, edibles, dabs and more. Let’s quickly review the distillation process, then we can discuss the common equipment used for this process.

Distillation is essentially removing the remaining compounds of a mixture in order to create a nearly pure product containing only CBD, THC or other desired compounds. The process uses heat and vacuum pressure to remove the other materials in the mixture without damaging the cannabinoids and other materials that are intended to be in the product.

A very important part of this process is thin film technology. While the vacuum pressure and heat will remove water, solvents and other molecules in the extract on its own, the process is much more efficient when a thin film of oil is created on an evaporative surface. Let’s go into this in a little more detail.

A thin film of oil is intentionally made on the inside surface of a distillation machine in order to purify more efficiently. This is because less heat is required to volatilize, or boil the solvents in the extract when it is spread out. An easy way to remember this is to think of water. If water is in a bucket, it will take a long time to evaporate, but if that same amount of water is poured across the floor, it will evaporate much more quickly.

There are a couple of common pieces of distillation equipment that are used to create this thin film needed for proper distillation. One is a rotary evaporator, commonly called a rotovap. This equipment uses a large, glass vessel that is continually rotated. This allows a thin film of oil to form on the inside of the glass vessel. Coupled with heat and vacuum pressure, the solvent evaporates and the distillate is collected in a separate vessel.

Another common piece of equipment for thin film distillation is a wiped film evaporator. While the principle remains the same, this piece of equipment uses a mechanical wiper that spreads the oil across the inside of a column which is heated under vacuum pressure to perform the distillation process. The use of WFE technology is helpful as the distillate is increasingly purified, the viscosity increases as well making the mechanical wiper more efficient than gravity like the rotovap.

How to Make Cannabis Distillate

Above, we’ve highlighted the methods of making CBD distillate from extraction, to winterization to distillation itself. This process will yield hemp based extracts that are incredibly pure that are used for a variety of popular CBD products on the store shelves today. But, what about the process of how to make cannabis distillate? What do you have to do in the distillation process to make THC extracts?

Well, we already covered it! CBD distillation and THC distillation are essentially the same process overall. While there may be some minute nuances in order to ensure a quality extract like vacuum pressure and temperature, the process of distillation that removes solvents and other residual compounds remains the same. A thin film of oil is created using one of the methods we mentioned earlier. Then, vacuum pressure and heat are applied in order to volatilize the solvent from the extract.

But, there are important considerations to remember when making this kind of extract. In CBD distillate, delta 9 THC cannot exceed 0.3% in a final extract in order to remain legal. Because these extracts are made from hemp, there are low levels of delta 9 THC in the plant to start with. So, THC is a concern in CBD distillate, but it is a very simple issue that can be solved through methods like chromatography or dilution.

Then there is cannabis distillate itself. Because this form of distillate is made from the cannabis plant, it will be primarily delta 9 THC in the extract itself. This is because delta 9 THC is the most prevalent cannabinoid in the cannabis plant that can be extracted. So, after distillation, you can expect a cannabis distillate to have a delta 9 THC content of 95% – 99% purity.

The most important thing to remember about cannabis distillate is its legality. In all but 12 of the United States, cannabis is legal in either medical or recreational use. So, in those states in which it’s legal, the manufacture of cannabis distillate is permissible to be made for recreational or medical use. In those states where it is not legal, a distillate must not contain more than 0.3% in order to be federally legal.

Calculate Your Cannabis Business Operating Cost

Starting a Cannabis Business? Check out our Calculators and to analyse costs, estimated revenue, yield, initial investments and important metrics for your extraction business.

Distillation Trends That Make the Best CBD Distillate

To create a pure CBD distillate that is up to the current standard of quality and safety, high quality distillation equipment and the latest technology must be implemented. This is where extrakLAB continues to shine as one of the leading producers of hemp processing equipment in the industry today.

The latest trends include:

- GMP compliance

- Reduced maintenance

- Automation

- Integrated continuous solvent recovery and distillation

What is the Process to make CBD Distillate?

The process of distillation in the simplest of terms is the separation of two substances based on their different boiling points. A typical distillation machine will consist of some form of heated evaporator, and a chilled condenser to collect the desired product after evaporation.

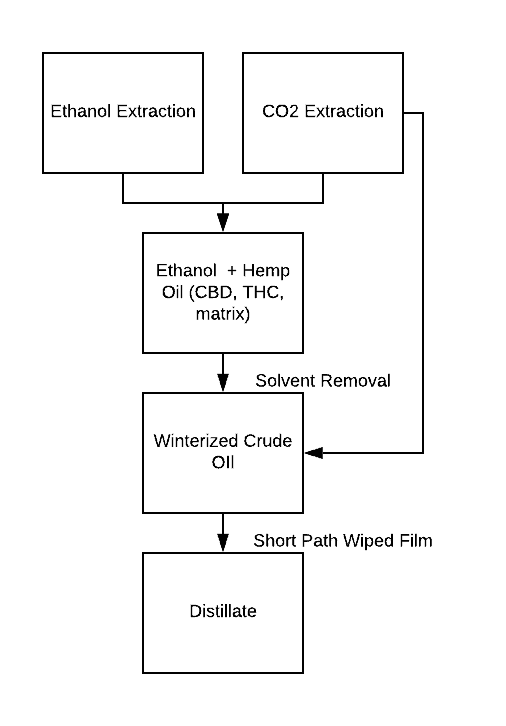

As is shown in the adjacent figure, this process uses CBD oil that is dissolved in ethanol from an ethanol extraction or from supercritical CO2 extraction.

Before the process of distillation begins, we’ll highlight the equally important steps prior to short path distillation.

Step 1. Winterization

In order to remove waxes, the oil and ethanol are chilled down to typically less than -20℃. The waxes precipitate as a solid because they are no longer soluble.

Step 2. Filtration

Filtration of the waxes and separation from the cold ethanol oil is the next step. This can be quickly and easily accomplished with a DrainDroyd. The DrainDroyd

extraktLAB’s DrainDroyd is the leading filtration technology for dewaxing winterized crude oil.

is a simple, high throughput filter system that separates waxes from the oil.

Step 3. Solvent Removal

Solvent removal is necessary to recover, or remove solvent from CBD oil after ethanol extraction or winterization. A rotary evaporator, commonly referred to as a “rotovap,” is a common way to accomplish recovery of solvents. The equipment uses a rotating round bottom flask, vacuum pump, heating bath, chilled condensation surface and collecting flask. The vacuum pump is necessary to reduce the boiling point of solvents like ethanol. The ethanol boiling point is roughly 78.2℃¹ compared to a relative boiling point of 160-180℃ for CBD. So, the first step is to remove the solvent before short path molecular distillation.

Final Steps in Making CBD Distillate

Now let’s dive into the distillation process. In order to get a golden clear CBD distillate, residual plant matter, terpenes, some organic compounds need to be separated from the CBD. A short path wiped film distillation machine is the preferred way to get this done.

While standard short path equipment is capable of large quantity solvent removal, creating a CBD distillate that is both potent and safe for customers is reliant on removing as many undesirable compounds from the mixture as possible. These residuals could contain materials that could either reduce potency, or be unsafe for consumers. So, what’s next?

Get To Know the Trendy fracTron 1000 and clearSTILL 400

extraktLAB’s commitment to create the most advanced technology in the hemp extraction industries leads to the latest in distillation equipment: the fracTron 1000, and the clearSTILL 400. Both of these thin film evaporators have raised the bar in efficiency, processing and GMP compliance that leave competitors behind the curve.

fracTron: 3-Stage Falling Film Distillation

The fracTron 1000 incorporates the latest trends in falling film evaporators including GMP compliance, automated methods, reduced handling of oils, and seamless, continuous integration with clearSTILL 400. The falling film evaporator is well equipped to remove solvents from liquid mixtures at a very high throughput by evaporating the more volatile materials.

extraktLAB’s falling film distillation evaporator, the fracTron

The fracTron 1000 is a Fast Machine

The capability of three independent fractional separations contained in one process allows for a 40 gallon/hour throughput with a continuous process flow. This significantly reduces labor costs and completely removes solvents without the need for secondary processing.

The fracTron 1000 is Continuous

Because of the ingenuity of the fracTron 1000’s triple pass system, residual solvent removal is more efficient than ever. With a typical single stage falling film evaporator, a single temperature setpoint is set within the distillation column and the operator has to load batch after batch manually. This batch process is similar to a rotovap. The fracTron 1000 enables temperatures to be adjusted within each stage independently to provide three pass solvent removal in one continuous step. This makes the difficult process of removing final remaining solvents much more effective than single stage thin film evaporators.

The fracTron 1000 reduces Maintenance

The fracTron 1000 is enabled with many advanced maintenance reducing features. The number one feature is the automated cleaning methods and also integration with our clean in place system.

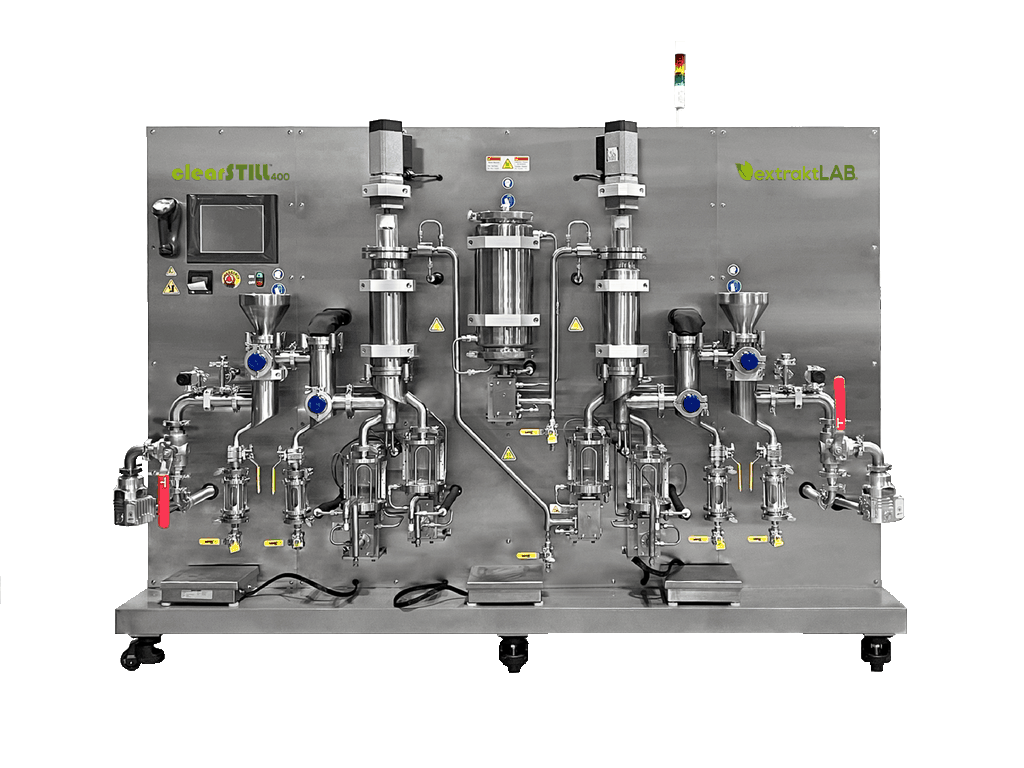

clearSTILL: Two-Stage Short Path Wiped Film Distillation

extraktLAB’s clearSTILL 400 is the most advanced wiped film evaporator on the market. The equipment eliminates the headache of single pass distillation and can be fed directly from the fracTron 1000. By completing two independent distillation passes within a single contained cycle, the clearSTILL 400 is capable of doubling throughput and halving labor costs all while creating a clear gold CBD distillate.

extraktLAB’s wiped film distillation machine, the clearSTILL

clearSTILL 400 is Continuous

Though other wiped film distillation methods have been used within the industry, the vast majority are using single stage wiped film distillation equipment. This creates a bottleneck in the production process that forces producers to transfer hemp oil from one pass to the next. Not only does this increase downtime, it also opens the opportunity for product waste and contamination.

clearSTILL 400 Throughput

The clearSTILL 400 is capable of a throughput capacity of 4-6L per hour and raises the potency of winterized oil from a typical 50-65% to 65-90% in the final distillate. This upgrade in production value and overall quality in distilled hemp products is sure to make an impact in any business in the hemp extraction industry.

clearSTILL 400 has Reduced Maintenance

One of the key advantages of clearSTILL 400 is that it uses vacuum pumps that are oil-less. This means that maintenance of the roughing vacuum pumps is much less compared to other systems on the market.

Common Features on Both the clearSTILL 400 and the fracTron 1000

A distilled marijuana or hemp plant product should reflect the dedication of a company to the quality of their equipment. Like all extraktLAB’s co2 extraction and distillation equipment, the fracTron 1000 and clearSTILL 400 are designed with GMP compliance in mind with stainless steel construction that meet global market requirements.

Batch Record Quality

extraktLAB offers an add on GMP package that will give your quality staff a complete set of physical data needed for compliance. There are also several features built into the unit itself that will greatly aid in automating batch records including: 21CFRpart11², GAMP5³, Annex 11 compliance, paper receipts, barcode input of metadata, tracking of methods run, tracking of maintenance and calibration data, and much more.

Programmable methods that aid in pressure, flow rate, alarms and temperatures are critical in final product quality are available in the fracTron 1000, clearSTILL 400 and all extraktLAB machinery.

The fracTron 1000 and clearSTILL 400 Both Run Automated Methods

The fracTron 1000’s three stills are capable of independent control during a single process, including temperature. In order to accomplish this, the operator loads a desired method that specifies the temperature, pressure, flow rate and time. With a single touch, a different method can be loaded. Further, as we will see below, solvent removal and distillation can be linked together to provide a continuous process.

How to Automate Solvent Removal and Distillation

Connecting solvent evaporation and wiped film distillation Into a single continuous process is a snap as is shown in the figure below. Normally, an operator would do three separate passes to remove the ethanol, then cook the oil in a stirred reactor to decarb or remove terpenes, then distill the oil with several passes. This process is fraught with delays, inventory, lost labor, lost materials and is simply inefficient.

Full automation of solvent recovery and wiped film distillation is possible with fracTron 1000 and clearSTILL 400 integration

Automation of solvent recovery and distillation is probably one of the greatest targets of opportunity to help with efficiency gains. As is shown above, only an insulated connection pipe and ultrasonic level sensors that are incorporated on the unit are needed to make this a reality. Each unit is programmed to enable continuous operation.

Conclusion

When it comes to trending topics in the world of hemp distillation, extraktLAB has led the way in innovation. If you’re ready to join the rest of the winners in the industry, contact us at 651-600-0036 for the best possible efficiency, production value and product quality in the business.