Are you a hemp cultivator harvesting your hemp crop this fall? Are you increasing your overall worth of your crop by bucking your hemp?

Hemp bucking is a crucial factor in finding a potent, valuable extract down the manufacturing line, and you will need the ideal equipment to do it right. In this article, we explain the significance of hemp bucking, how it makes your crop more profitable and how the shuckNbuck is the best method to get the job done right.

What is Hemp Bucking?

Bucking of hemp is an important part of hemp extraction and processing. A hemp bucking machine can reduce the labor needed to remove the bud from the stems. This procedure is frequently called “de-budding” or “de-stemming.” Removing the high cannabinoid containing hemp buds from the lesser needed stalks and stems is important down the line in your extraction procedure.

Reasons For Hemp Bucking

Reducing the weight of waste in your biomass like stems, sticks and seeds drastically affects the overall potency of your biomass and extract down the line.

If you are not “cleaning” your own biomass by eliminating the stalks and stems which do not contain large CBD percentages, then you are diluting the overall percentage of CBD in your extracted oils.

To put it simply: The lower the CBD percentage point of your hemp crop, the lower your profits.

The flower or “bud” of the hemp plant contains the majority of cannabinoids making it important to remove them from the stem using hemp bucking

And of course, before anyone will buy your hemp they’ll need to sample it. While incorporating the bulk of stalks, stems and fan leaves to boost raw material weight may seem like a practical idea, it will automatically reduce your CBD percentage points and cause a much less profitable product in the end.

Depending upon your hemp bucking machine, it can grind your biomass as well, expediting your pre-extraction process and efficiently optimizing your valued biomass to pull high quantities of CBD. Grind size becomes a critical factor for producers who want to make the best CBD extracts they can.

Why Grind Size is Important for Efficient Extraction

Grind size is a significant consideration during the extraction process for many reasons based on the extraction method. Here are some key details for that are important to consider for grind size:

The preferred grind size is small with CO2 extraction in order that the more materials can be packed to the pillar. A little particle size wheel packs efficiently into the column and thereby prevents channeling within the pillar.

Increased mass transport is the second reason a small grind size is desirable. The larger the particle size, the more the cannabinoid will take to diffuse out of this particle and to the flowing stream.

The smaller the particle size the greater the mass transfer will be and also the shorter time the cannabinoid will require to diffuse from this particle. This can be true for both ethanol and CO2 extraction.

One important facet of grind size is particle size distribution. For particles of all of the same size, extraction is more uniform. But for a combination of tiny particles and large particles, the smaller particle will be extracted before the larger particles.

This further illustrates that grind size is critical for the most optimal particle distribution that will yield the best extraction efficiency.

Process Your Harvest Using a Hemp Bucking Machine Designed for Efficiency

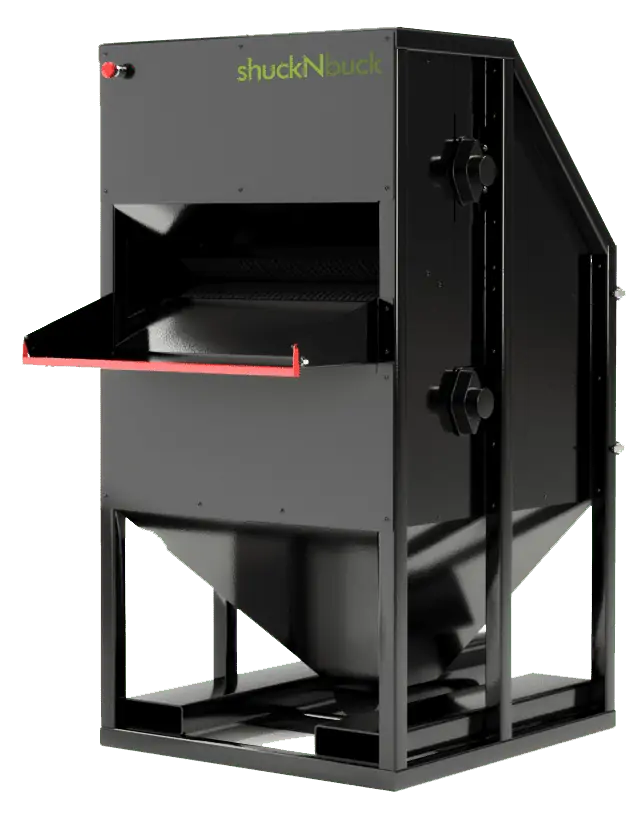

extraktLAB’s answer to hemp bucking, the shuckNbuck, is a high-speed hemp bucking machine designed for indoor or outdoor use. It delivers the capacity to

The biomass is deposited neatly in your container of choice for storage or shipment. The shuckNBuck is by far the fastest machine for hemp bucking on the market. Capable of processing more than 1 acre of dry industrial plants in around three hours, the shuckNbuck generates processor-ready ground material.

The powder-coated carbon steel construction and 1 HP motors allow quick bucking with little to no effort. The shuckNbuck includes detachable polypropylene food-grade brushes. The flexible brushes are capable of creating ground hemp for with a perfect grind size for extraction. The unit works best at low moisture content of 15% moisture or less.

How the shuckNbuck Works in Five Easy Steps

1. Harvest the whole hemp plant.

2. Dry the hemp to less than 13% water weight.

3. Feed every plant into the shuckNbuck while holding onto the stem.

4. Pull stem out of the machine.

5. Collect the bucked material in a storage or shipment container.

Advantages of shuckNbuck Hemp Bucking Machine

- 5 Second Processing Speed

- 2000 plant processing per hour

- One-man operation

- Immediate Fill of “Super Sack” Containers for quick extraction

- Optimized for indoor and outdoor Use

- Lowest processing cost on the market.

- The shuckNbuck can be trailer mounted and run from a generator to get in field hemp bucking.

Easy Loading

The bucking machine is designed for ease of use including simple loading of the hemp biomass, easy removal of CBD rich hemp buds, and automated separation of waste weight like stems and stalks. This eliminates the need for secondary conveyors to manage the remaining stalks, stems and hemp flower.

Easy Maintenance

Designed specifically for hemp processing, the brushes are food quality. The brushes can easily be maintained by the operator and adjust easily so that plants with varying weights may be shucked, destemmed, or debudded.

Extremely Fast

The ShuckNBuck hemp bucking machine has a high power motor that permits high throughput hemp bucking with just one operator needed to process 1 acre per hour.

Safety First

The shuckNbuck has three safety measures installed: a bump bar on the front below the loading zone, an e-stop button on the front top over the loading zone, and a kill button that is activated if the back door is opened.

Take Hemp Bucking to a New Level with shuckNbuck

Interested in adding the shuckNbuck to your hemp processing solution? We’re here to help. Give us a call at: 651-464-2822 to find out how you can optimize this important step in hemp processing and extraction.