Supercritical CO2 Extractors

Highest Throughput – Lowest Operating Cost

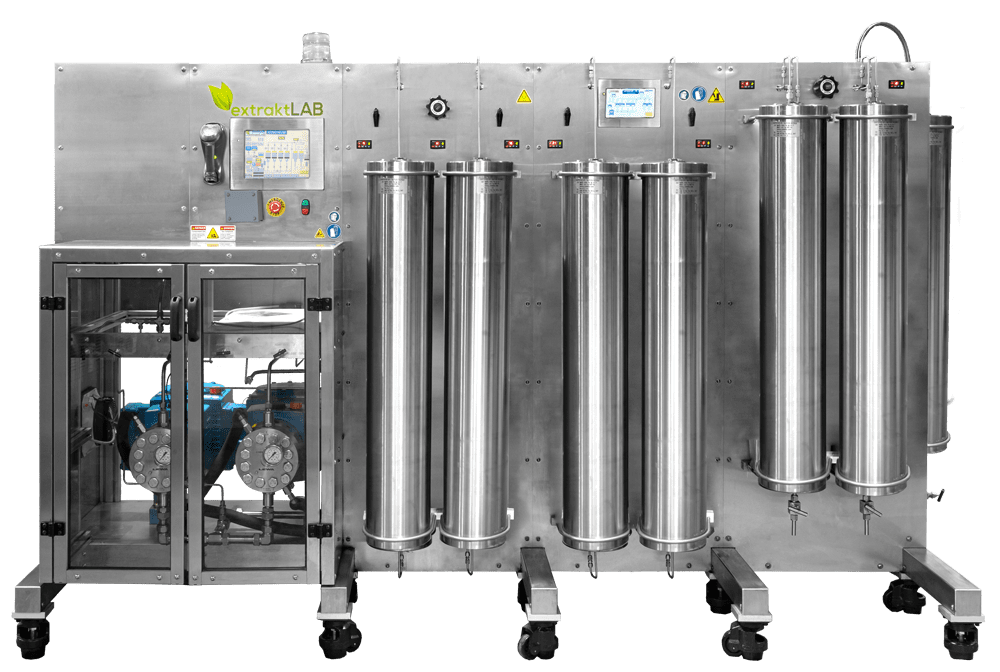

extraktLAB’s supercritical CO2 extractors deliver the highest daily throughput of biomass processing in the industry, while also delivering the lowest processing costs of output oil.

Supercritical CO2 extraction is recognized as the safest, cleanest, and most efficient way to extract botanical oils and waxes. Extraction machine throughput and efficiency are the fundamental contributors to revenue potential of botanical extraction and hemp manufacturing lines.

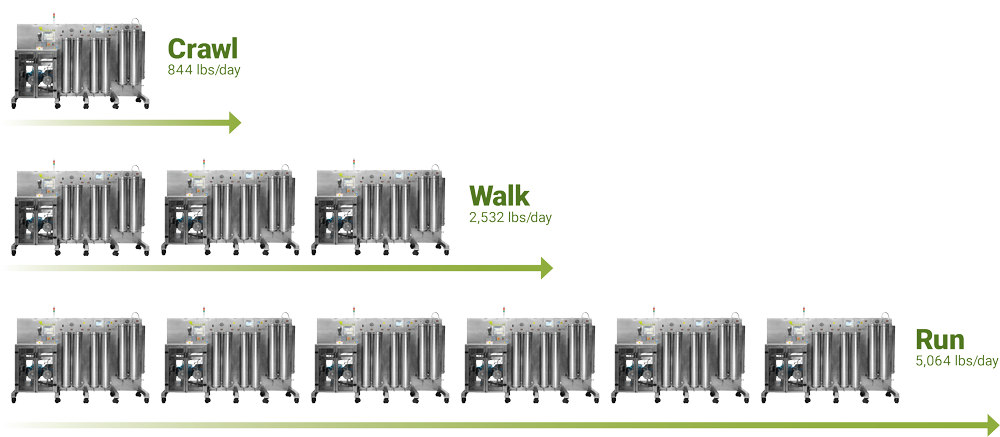

Scale Up Your Capacity One Step At A Time – We Can Show You How

Benefits of extraktLAB supercritical CO2 Extractors

extraktLAB’s supercritical CO2 extraction equipment delivers the highest throughput and efficiency for CO2 extractors in the industry. Our extractors also offer:

- The lowest operating cost

- The smallest footprint

- Low power consumption

- Low labor requirements

- Unlimited scalability

extraktLAB extractors provide a solid foundation for manufacturing businesses of any size. We make it easy to scale up to match customer demand.

Get in touch with our team to request a quote, learn more about our training or get help with your business plan.

We are dedicated to providing you with the best advice, quality and service in the industry.

Models

exraktLAB's e-110

For smaller producers or research labs that need a small footprint.

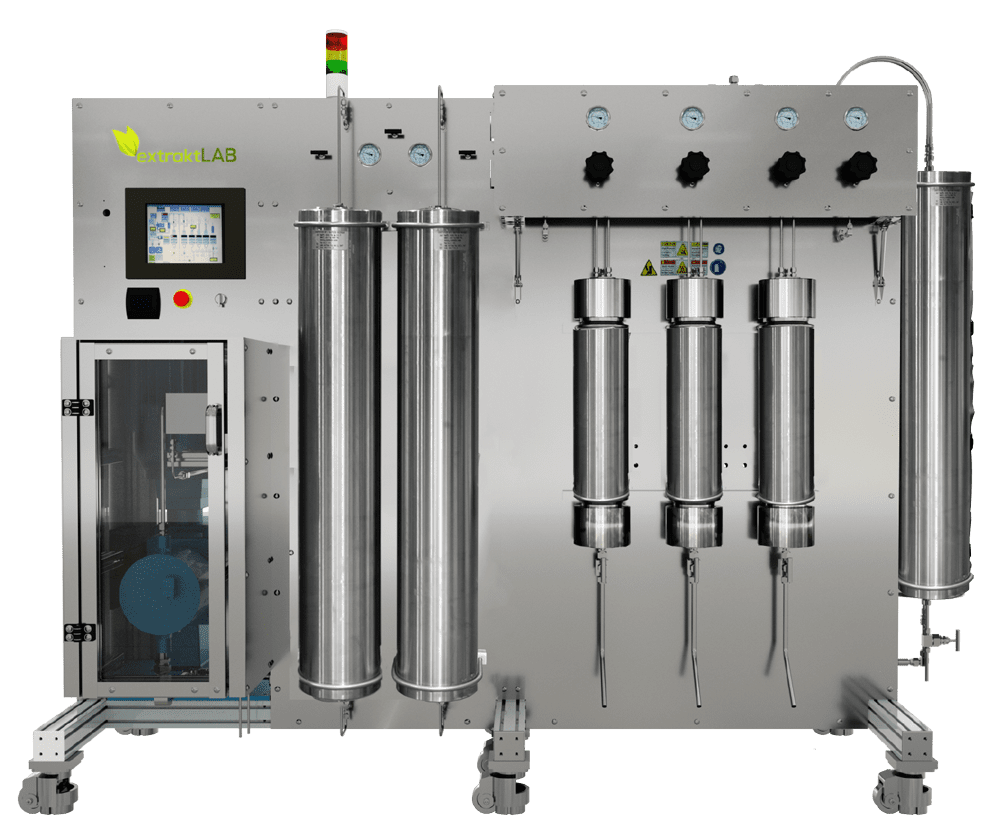

extraktLAB's e-140

For larger producers who want to scale up capacity.

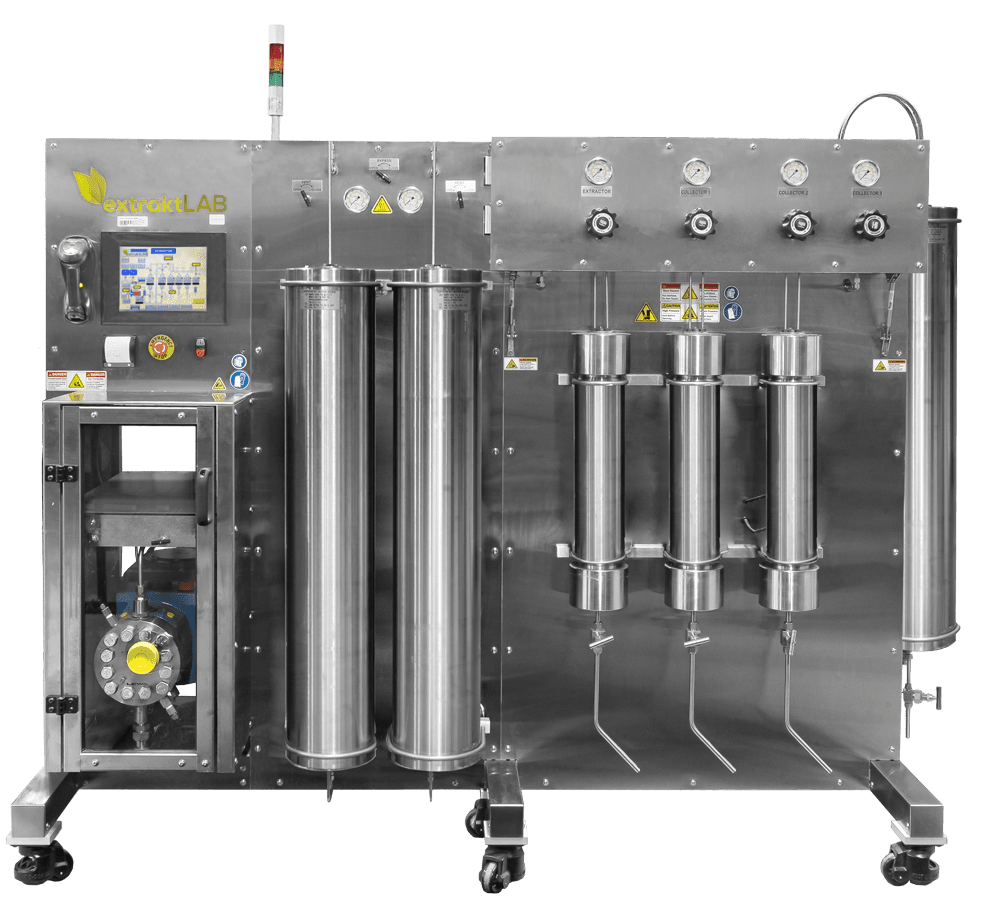

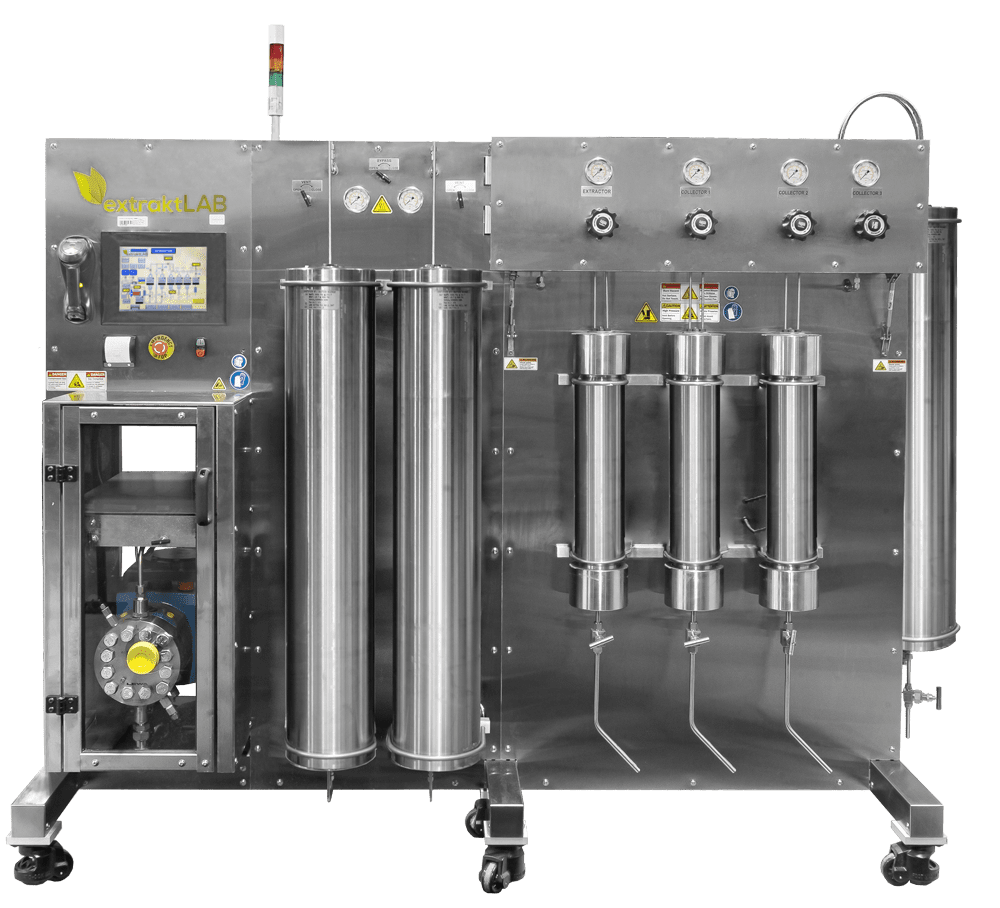

extraktLAB's e-180

For larger producers who want to scale up capacity.

Certifications

Testimonials

Technicians were super supportive and provided valuable tips. Equipment works great!

Your support tech was terrific. He knew the instrument in-and-out, was incredibly knowledgeable about extraction chemistry, and worked tirelessly to give us terrific service. He gave us every insider trick that he had learned in running the instrument for years. I can’t wait to have him back out to my laboratory. Truly exceptional worker! Couldn’t say more positive things!

Specifications

|

EXTRAKT-110 |

EXTRAKT-140 |

EXTRAKT-180 |

|

| Biomass Input / Cycle | 1-1.5kg | 5-8kg | 10-16kg |

| Cycle Time @ 10% pp | 60 min | 60 min | 60 min |

| Biomass Processing / Day | 36 kg / 79 lbs | 192 kg / 422 lbs | 384kg / 844 lbs |

| Efficiency – Oil Recovery | Hemp 90+% | Hemp 90+% | Hemp 90+% |

| Extraction Vessels | 2 × 5L | 2 × 20L | 4 x 20L |

| Collection Vessels | 3 × 2.5L | 3 × 2.5L | 2 × 20L |

| CO2 Recycle Vessel | 20L | 20L | 20L |

| Footprint | 24 sq ft | 24 sq ft | 48 sq ft |

| Shipping Weight | 3,000 lbs | 4,300 lbs | 6,200 lbs |

| Dimensions (w/o light mast) | H 72” × L 99” × W 34” | H 72” × L 99” × W 34” | H 72” × L 129” × W 53” |

| Operating Pressure | 0 to 5,000 psi | 0 to 5000 psi | 0 to 5000 psi |

| Operating Temperature | 25 to 100°C | 25 to 100°C | 25 to 100°C |

| Sound Pressure | 40 db | 50 db | 50 db |

| User Interface | Touch Screen HMI Panel | Touch Screen HMI Panel | Touch Screen HMI Panel |

| Full Load Amps | 57 | 67 | 85 |

| Voltage | 208-240 VAC | 208-240 VAC | 208-240 VAC |

| Phase | 1 | 3 | 3 |

| Frequency | 50-60 Hz | 50-60 Hz | 50-60 Hz |

| Flow Control | Manual or Automatic | Manual or Automatic | Manual or Automatic |

| CO2 Supply | 750-850 psi inlet | 750-850 psi inlet | 750-850 psi inlet |

| Wetted Materials | FDA approved, ASME 304 and 316 Structural Grade Steel | FDA approved, ASME 304 and 316 Structural Grade Steel | FDA approved, ASME 304 and 316 Structural Grade Steel |

| Separation Principle | Cyclonic | Cyclonic | Cyclonic |

| Datasystem | Export data, diagnostics and event logging, data traceability, unlimited working level access, user traceability method, CO2 lot, input lot trace | Export data, diagnostics and event logging, data traceability, unlimited working level access, user traceability method, CO2 lot, input lot trace | Export data, diagnostics and event logging, data traceability, unlimited working level access, user traceability method, CO2 lot, input lot trace |

| Regulatory Compliance | 21 CFR Part 117,211, 177 and Health Canada equivalents, P.E. stamped according to ASME DIV II VII-2 PED compliant, CE marked, notified body Lloyd’s Register, CRN number | 21 CFR Part 117,211, 177 and Health Canada equivalents, P.E. stamped according to ASME DIV II VII-2 PED compliant, CE marked, notified body Lloyd’s Register, CRN number | 21 CFR Part 117,211, 177 and Health Canada equivalents, P.E. stamped according to ASME DIV II VII-2 PED compliant, CE marked, notified body Lloyd’s Register, CRN number |

| Cleaning Methods | Supercritical CO2, alcohol, non-polar solvents | Supercritical CO2, alcohol, non-polar solvents | Supercritical CO2, alcohol, non-polar solvents |

| Calibration / Maintenance | Software tracking built-in | Software tracking built-in | Software tracking built-in |

| Training records | Software tracking built-in | Software tracking built-in | Software tracking built-in |

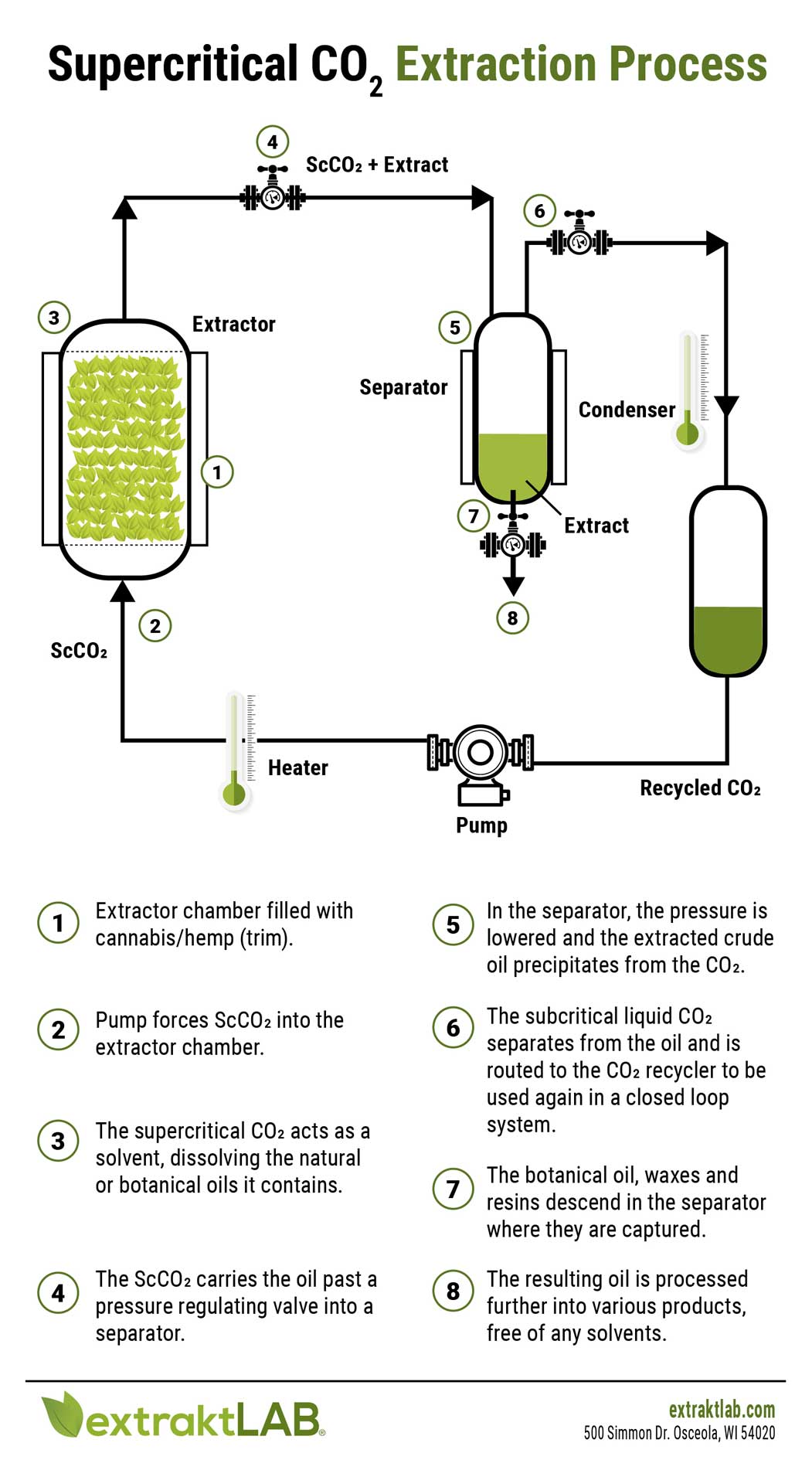

The Science Behind Supercritical CO2 Extraction

Supercritical CO2 (ScCO2) extraction has become the preferred method for extracting THC and CBD oils to serve markets with the most demanding standards for safety, quality, purity and consistency. It is also preferred by consumers for the same reasons, and progressive brands are boldly stating “ScCO2 extraction” on package labels.

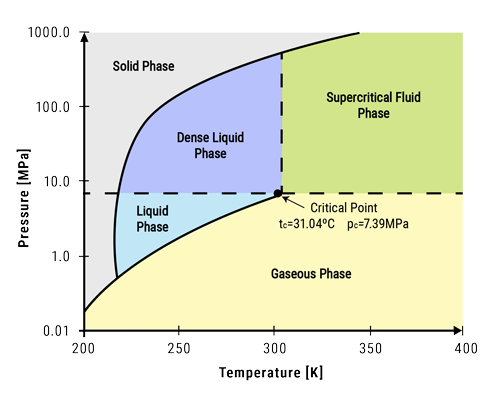

Supercritical CO2 extractors use carbon dioxide (CO2) at an elevated temperature and pressure to extract soluble compounds from natural products. Carbon dioxide above the critical temperature (31ºC) and pressure (1071 psi) becomes a supercritical fluid, which has an increased capacity for solubilizing non-polar compounds. Raising the temperature and pressure of the liquid CO2 even further provides highly efficient extractions of oils in a short period of time.

We are dedicated to providing you with the best advice, quality and service in the industry. Get in touch with our team to request a quote, learn more about our training or get help with your business plan.