Operating Costs of Starting A Cannabis Extraction Business

Thinking of starting an extraction business?You’re not alone. Check this article for CBD extraction machine cost that you need to know. With the passing of the 2018 Farm Bill legalizing hemp production, the extraction industry has seen a boom in the last six months. There’s never been a more exciting or lucrative time to work in extraction, but there are a few things you need to keep in mind before jumping in feet first.

In this article, we will cover hemp processing starting from farming and harvesting to producing end products. You will learn what CBD processing equipment is needed for effective CBD processing in each step.

We will also explain how CBD oil is extracted and what CBD oil extraction machine is best to complete the process.

We will share a list of the important features and factors to help you choose the right CBD extraction equipment for your hemp extraction business, and highlight extraktLAB’s leading-edge, supercritical CO2 CBD oil extraction machine.

By the end of this article you’ll discover how extraktLAB’s equipment has the lowest operating costs, fastest throughput, smallest footprint, and most scalable design in the CBD oil extraction industry.

Introduction

Over the last several years, there is no doubt that there has been a boom in the CBD oil extraction machine industry.

According to the latest reports, we should expect substantial market growth of hemp and CBD production by 2023. As the demand for hemp and CBD productions increases we see the incredible variety of products and services stemming from it.

Hemp is a particular species of plant grown for industrial use. The process of harvesting and using this plant has existed for tens of thousands of years and is continuing to grow exponentially. This includes the production of clothing, paper, paints, food products, biodegradable plastics, and more.

Hemp has a low amount of psychoactive cannabinoids (what is traditionally known to cause a “high”) in the plant. The plant also contains a common cannabinoid, cannabidiol (CBD), which has many reported health benefits.

Recently, producers have discovered how to make CBD oil in full-scale production, opening a new profitable industry.

The growing list of uses of the hemp plant makes it a virtually limitless plant. However, to access its benefits, hemp has to be processed into usable materials, like textiles or CBD oils. For this purpose you will need to use specialized CBD processing equipment to harvest, dry, extract, and process hemp.

As you read further, you will learn how the CBD oil extraction process works to extract CBD oil and the purpose behind CBD extraction. We will also highlight the right type of CBD extraction and the best CBD extraction method you can use in your CBD processing startup.

It is important to note that there are key features and factors to consider when choosing CBD extraction equipment for your CBD or hemp extraction business.

CBD Oil Extraction Machine: How to Extract CBD Oil

CBD is a compound that has a variety of potential medical applications such as relief from anxiety and pain. CBD is different from Tetrahydrocannabinol (THC), a compound that makes users high.Therefore, it is considered safe for most people.

There are several practical ways to extract CBD oil from hemp. Some CBD extraction systems used CO2 as a solvent in the process of oil extraction. Using CO2 as a solvent is a pure and clean form of CBD oil extraction as there is no residue after extraction.

The extracted CBD oil has to be refined after extraction in order to isolate CBD and other individual compounds. This is achieved with the help of three processes conducted one after another. They are called winterization, solvent removal and distillation.

To perform effective CBD oil extraction, a suitable solvent is very important. Effective CBD oil extraction depends on the capability of the solvent to strip the CBD from the hemp biomass.The column containing the ground hemp biomass is injected with the solvent of choice which will then act on the CBD in order to remove it from the plant material where it can be collected and refined downstream.

There are few practical methods of CBD extraction; however, the best method for CBD oil extraction is supercritical CO2 extraction. CO2 extraction is the most environmentally friendly extraction method as well as the most consumer safe extraction method.

CO2 CBD extraction is also much less expensive than other extraction methods in terms of long-term operational costs. In terms of solvent loss, solvent cost, and operational costs, it is a proven profitable extraction method when compared to other extraction methods over just one year.

extraktLAB manufactures cutting-edge, supercritical CO2 extraction equipment for hemp and botanical extraction industries.

Our CBD oil extraction machine has the fastest throughput, lowest operation costs, smallest footprint, and most scalable design in the CBD oil extraction industry.

We operate a 10-ton/day processing facility within our 38,000 sq ft manufacturing and demo facility in Wisconsin.

Contact extraktLAB today to learn more about leading-edge hemp oil extraction machines.

CBD Processing Equipment for Effective CBD Processing

As mentioned previously, there are numerous products that come from hemp processing. These products are all derived from the cultivation of the plant that involves hemp farming – planting, harvesting, shucking, separating, formulating, and creating final products.

Harvest and use of hemp include the production of clothing, paper, paints, biodegradable plastics, food products, and more through the processing of hemp. Recent uses of hemp include the practice of extraction and use of cannabidiol (CBD).

Recent research claims that high-quality CBD oils may have numerous health benefits. Today, you can find anything from skincare products, to edibles, to vaporizers that contain CBD.

In order to create CBD products, hemp has to be processed into usable materials with the help of specialized equipment for harvest, drying, extracting, and processing hemp.

Let us have a quick look at hemp processing equipment, such as combines, CBD hemp harvesters, and decorticator.

Hemp farmers use the combines to collect bulk hemp stalks for industrial use. However, this machinery drastically reduces the capability to create quality CBD oils by compromising the quality of the hemp flower.

One more piece of equipment used in CBD processing is a CBD hemp harvester. This machinery cuts the hemp flower at the stalk more carefully and loads the crop together, reducing any damage to the CBD flower.

Lastly, is the decorticator. This is used to create any kind of industrial bulk hemp crop product. Decorticators are used by the processor to separate the fibrous internal material from the stem of the hemp.

After the hemp plant is carefully harvested, it is run through the shucking procedure. At this stage, special equipment is used to separate the flower from the rest of the plant material.

This separation is crucial as the hemp flower has a much higher CBD content than the other parts of the plant.

Once the separated CBD flower and seeds have been tested for any unwanted materials, they are to be prepared for CBD extraction.

CBD extraction equipment can differ greatly depending on the end result needed. It could be a simple food-grade alcohol extraction done in a home setting or a large-scale CO2 extraction.

Supercritical CO2 extractors are considered to be the most advanced, efficient, and powerful extraction equipment in the hemp and botanical extraction industry today.

extraktLAB’s extractors are powerful, efficient, and practical for those producers who want the highest possible quality while achieving efficient productivity.

You will need to have at least four different employees in order to run a CBD processing or CBD extraction facility, this includes:

- quality assurance manager

- shift manager

- operator

- analytical operator

A quality assurance manager will help you comply with GMP requirements and produce a quality CBD product.

It is crucial to have a quality assurance manager at your CBD processing or extraction facility who is aware of the requirements and can implement those in your business.

A shift manager will organize and schedule operators at each station and track the production output. The manager will also be responsible for operator training, yields, workforce management, meeting quality requirements of the end product.

Operators are needed to execute the production plan following standard operating procedures. They should be trained on how to use the equipment and how to move materials in and out of the process.

The operators are responsible for recording the data for the quality management system and basic equipment maintenance.

Analytical operators, or quality control technicians, are typically chemists and have a laboratory background. They are important to provide yield and in-process testing to the manufacturing facility.

An analytical operator works with quality assurance to ensure that incoming raw hemp biomass conforms to purchasing and quality specifications.

At extraktLAB, we manufacture leading-edge, supercritical CO2 extraction machines primarily used by the hemp and botanical extraction industries. Our equipment is renowned for having the fastest throughput, smallest footprint, lowest operating costs, and most scalable design in the CBD oil extraction and processing industry.

Contact extraktLAB to learn more about the exciting and most cost-effective CBD oil extraction opportunities available in the industry today. You can call us at 651-600-0036 or submit an online form for more information.

How Does CBD Extraction Work?

Whether you’re considering buying CBD extraction equipment or already own some, you should be aware of how it works.

Let’s find out how to use a CBD extraction machine, how it works, and its purpose in the extraction process.

How to use a CBD Extraction Machine

Before you jump straight into its working principle, some considerations are important. To perform effective extraction, a suitable solvent like ethanol or butane is very important. That’s because effective extraction depends on the capability of the solution to act on the plant.

The solution goes from the operating tank to the extraction cylinder. The solvent acts on the plant to extract much desired plant components.

How it Works

The underlying principle of CBD extraction is pretty much the same in all CBD extraction machines. The typical process in CBD extraction equipment runs in a cycle. Let’s see how it works:

- First of all, the solvent goes into the operating tank where plant material is present already. The solvent is injected into the operating tank.

- The next step is the movement of solvent from the operating tank to the extraction cylinder.

- Once the process in the extraction cylinder is complete, the extract pours into the vessel. Here, the solvent begins to vaporize. The highly pressurized solvent is released into another chamber.

- In the next phase, the solvent travels through an expansion filter. This process can speed up by applying some heat to the expansion filter.

- In the next step, the solvent vapor escapes the expansion filter and moves into the recovery pump.

- In the final phase, the solvent drains into the recovery pump.

The process keeps happening in a cycle until you get crude CBD oil.

What is its purpose?

Considering the benefits of hemp, a CBD extraction machine is extremely important. The prime objective or purpose of CBD extraction equipment is to extract and produce high-quality consumable hemp oil.

How much does a CBD Extraction Machine Cost?

There are a number of factors that contribute to the overall costs of a CBD extraction machine. These include the method of extraction being used, the amount of extract you plan to make, the products you intend to put on the market, the size of the extractor, the operating system of the extractor, etc.

The truth is a CBD extraction machine can range anywhere from a few thousand dollars to half a million dollars or more depending on the technology itself. A smaller extraction system for R&D purposes can be considered a “desktop” extractor and can use a number of solvents in order to extract CBD. This can be hydrocarbon, ethanol or CO2.

For any size extractor, hydrocarbon and ethanol extraction equipment is generally much less expensive than supercritical CO2 extraction equipment. This is because CO2 equipment is highly specialized to handle the operating pressures necessary for CO2 to reach its supercritical state that makes it efficient for extraction.

So, where an ethanol extractor may cost $5000, a comparable CO2 extractor could cost potentially $10,000. Again, there are a variety of factors that play into this pricing, but it can be reasonably expected for a CO2 extractor to be nearly double that of ethanol or hydrocarbon equipment.

Then there is the operating system of an extractor. There are extractors that are entirely operated manually, and some extractors that are fully automated. The difference between these systems can be thousands of dollars which makes inexperienced operators lean towards a manual operating system. However, full automation can even itself out in terms of cost efficiency in a short period of time by reducing labor costs and fully optimizing an extraction operation so that its efficiency is at the highest possible level.

Of course, the size of an extractor no matter the extraction method used is directly proportional to the cost of the machine. While some extractors are designed to process 10 to 80 pounds per day and can cost tens of thousands of dollars, other extractors can be designed for industrial levels of hemp processing that can cost hundreds of thousands.

How CBD Is Extracted From Hemp

There are several methods that can be used to extract CBD from hemp. While they are different in their methods, the general principle remains the same. This involves stripping the CBD from the plant material, and then refining the extracted oil into a product that is a pure and potent form of CBD extract. Let’s take a look at the steps of extraction and the various methods used to extract CBD from hemp.

Step 1. Bucking and Grinding

In order to get the best yield from the process, it’s important to get the steps before the actual extraction process is optimized. This is why shucking and grinding are important. Shucking involves removing the high CBD containing flowers from the rest of the plant. Once they’ve been removed, they can be grinded into a consistency that allows the solvent to best strip the CBD from the biomass and get the best possible yield.

Step 2. Decarboxylation

While this is an optional step before the extraction process, we find that it is the best process for obtaining terpenes and improving extraction efficiency. This involves placing the plant biomass in a vacuum oven and heating the material until the CBD-A converts to the active CBD through the decarboxylation process. By connecting a cold trap collector to the vacuum oven, the terpenes from the plant can also be collected.

Step 3. Extraction

This step is the true extraction process. The plant material is placed into an extraction column where a solvent is introduced that is capable of stripping the CBD from the biomass so that it can be collected as a crude oil. This is most often accomplished using CO2, ethanol or hydrocarbons.

Step 4. Winterization & Filtration

This process is specific to CO2 extraction. It takes the winterized oil and introduces it to small amounts of food grade ethanol and sub-zero temperatures. This solidifies the fats and waxes from the crude oil so that they can be filtered and removed.

Step 5. Solvent Removal

This step is necessary to remove the remaining solvents from the extraction and winterization process. By applying heat and vacuum pressure, the solvents can be volatilized which evaporates them so that they can be removed from the extract. This is often accomplished by using a rotary evaporator or a falling film evaporator.

Step 6. Distillation

The final step uses the same principles as solvent removal, but with a more refined process. This removes any trace materials like solvents, terpenes, and other plant materials that will lower the purity or potency of a distillate. After this process is done, you will be left with a high quality distillate.

What to Look for in Hemp Extraction Equipment

Not everyone can do it, but with the right setup and equipment, you can completely optimize the hemp extraction process. The right equipment is highly critical to making the extraction process, cost-efficient, quick, and convenient.

Let’s find out what to look for in CBD Extraction Equipment

You need CBD Extraction Equipment that has the following features:

- Highest Yield and Daily Throughput.

- Smallest Footprint.

- Low Operating Costs.

- Unlimited Scalability.

- GMP Compliance Support.

- Training of Your Labor Force.

- Documented Standard Operating Procedures (SOPs) for All Processing Steps.

All of these features are available in extraktLab’s extractors.

extraktLAB’s line of supercritical CO2 extractors are the most advanced, efficient, and powerful extractors in the hemp and botanical extraction industry today.

With a throughput capacity from 79 to 844 pounds per day depending on the extractor model, the e-110, e-140, and e-180 extractors are powerful, efficient, and practical systems for producers who want the highest possible quality and productivity.

These extractors are designed to provide the highest throughput yield in the shortest period of time while satisfying the traceability requirements for GMP compliance.

extraktLAB’s supercritical CO2 extractor series are of the highest quality and productivity built with safety, efficiency, and overall quality in the extraction industry today.

Best Method for CBD Oil Extraction

When it comes to CBD extraction, there are quite a few methods that are practiced. However, the best method for CBD oil extractions is Supercritical Co2 extraction.

Supercritical CO2 extraction

Supercritical CO2 extraction is practiced to extract the desired substance from plants. One of its major uses is in the extraction of CBD oil from hemp. CO2 extraction offers excellent hemp oil extraction.

Working principle of Co2 Extraction

- Carbon dioxide is used at an elevated temperature and pressure to extract soluble compounds from the plant. Above the critical temperature, CO2 becomes a supercritical fluid, increasing its ability to solve non-polar compounds.

- Under supercritical conditions, carbon dioxide acts much like fluid solvents in terms of its solubility selectivity. It results in excellent extraction. By raising the temperature and pressure of the carbon dioxide, the process speeds up.

- When it moves through the biomass, the non-polar compounds get dissolved because the supercritical fluid breaks it down. Once this has happened, the liquid carbon dioxide reverts back to the gaseous state and leaves behind a “crude oil” that contains CBD.

Benefits of CO2 Extractions

So, we have seen how CO2 extraction occurs and why it’s effective for CBD oil extraction. Let’s look at its benefits to find out why it’s the preferred method for CBD oil extraction.

- The CO2 extraction system is the most environmentally-friendly extraction method. Because CO2 is considered a natural solvent, a producer can more readily become a certified organic manufacturer. With other extraction methods, there are risks of chemical residuals, which is not the case with the CO2 extraction method.

- It’s much less expensive than other extraction systems. If your preference is to obtain less expensive products, then CO2 extraction is the best choice.

- Since there are no chemical denaturants leftover because of this extraction method, it creates the safest products for customers.

Consider the Operating Costs First

However ripe a business opportunity extraction may be, building and maintaining momentum must involve a firm grasp and accurate calculation of operating costs and cannabis extraction equipment cost. For example, let’s say that a home brewer makes a new stout beer in his garage, and after selling a few batches to friends, decides to use his passion to launch a formal business.

After calculating his operating expenses, he determines that his operating cost to produce a pint of beer is about $2. This is a powerful piece of knowledge, as it can be used to calculate margin, project future revenue, and build a plan to scale up operations. Realistic calculations of operating expenses can mean the difference between expanding or closing your doors in the first six months.

Thinking of starting an extraction business? You’re not alone. Check this article for CBD extraction machine cost that you need to know. With the passing of the 2018 Farm Bill legalizing hemp production, the extraction industry has seen a boom in the last six months. There’s never been a more exciting or lucrative time to work in extraction, but there are a few things you need to keep in mind before jumping in feet first.

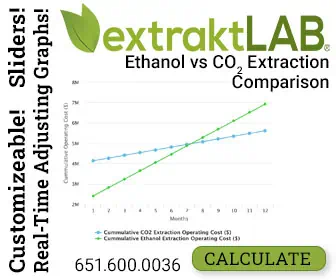

Calculate Your Cannabis Business Operating Cost

Starting a Cannabis Business? Check out our Calculators and to analyse costs, estimated revenue, yield, initial investments and important metrics for your extraction business.

Why Your Operating Costs Matter

Louis Mosca writes in Forbes, “Understanding your true operating costs will allow you to set realistic pricing in your bids/estimates/quotes. Without it, you could be seriously underbidding your products and services, with disastrous results.” It is powerful knowledge precisely because there is so much promise in doing it right, and so much risk in doing it wrong. Guesstimates aren’t going to cut it.

As the cannabis industry grows, the margins are going to become thinner. It is inevitable that large multinational corporations are going to enter the cannabis economy and try to claim a piece of it. When big players compete in the marketplace and consumers have real choices, the players with the lowest operating expenses can offer their products at more competitive prices, while still making a profit.

Comparing Costs: Supercritical CO2 Extraction vs. Ethanol Extraction

What factors contribute to a cannabis extraction lab’s operating expenses? There are several extraction methods that are popular, and some of the larger businesses use more than one method, depending on what they are manufacturing. But here we will consider only two: ethanol extraction systems and supercritical CO2 extraction. When formulating your operating costs which includes CBD extraction equipment cost, this list is a good place to start. Remember you want to calculate the cost to produce, for example, a gram of winterized crude CBD oil.

Input Biomass (Plant Material)

Unless you have a grow contract with a cannabis cultivator, surprisingly, this may be the most difficult thing to predict, as the fluctuation in prices could be caused by anything from government regulation to the weather. If you don’t purchase biomass, you’ll probably be looking to set up toll processing (flat fee for a set amount of processing) or split contracts (whatever product is produced is divided up) with the grower of the biomass. This is basically the same whether you are extracting with ethanol or CO2.

Outside Testing

Both extraction methods require testing by independent laboratories to ensure THC level compliance in CBD oil, and to ensure purity and consistency of product.

Packaging Materials

This list will vary based on the products you offer, but may include materials such as vape pens, cartridges, bottles, boxes, labels, packaging supplies, etc.

Maintenance

Supercritical CO2 and ethanol extraction both require the cleaning and maintenance of extraction machines and all participatory equipment, Buchner funnels, etc.

Differences Between the Two Extraction Methods

Labor costs

Wages, benefits, taxes, workman’s comp, insurance, training, and turnover are calculations found in any business’s operating expense calculation, regardless of extraction method. However, you should consider how many employees you’ll need to run the type of extraction equipment you utilize in your facility–as well as the education level required for operation.

Supercritical Extraction Machine

We have the perfect machine for small, medium and large producers. Our model line makes it easy for you to scale your operations while keeping your operating costs at a minimum.

CBD Extraction Equipment and Utilities

Costs vary greatly based on CBD extraction equipment and methods. Supercritical CO2 extraction is vastly more efficient than ethanol, requiring a single cycle to achieve efficiencies of 99%. This means CO2 extraction consumes less power, using only 67 amps to run an extraction cycle.

Both the extraction method and the CBD extraction equipment used will have a cost impact on overall production.

While ethanolic CBD extraction equipment tends to be generally cheaper in immediate costs, Supercritical CO2 CBD extraction equipment is often more cost effective long-term due to the drastically reduced processing cost of CO2.

That being said, not all CO2 extractors are frugal in their power consumption. Our extraktLAB 140 model optimizes output and minimizes cost and considered as top performing CBD extraction equipment in the industry.

Rent/Lease Space

The cost of the facility will vary greatly depending on extraction method. Supercritical CO2 extraction machines have a very small footprint and are easy to scale up, as they need no special infrastructure. However, ethanol extraction requires storing large amounts of ethanol. As it is highly combustible, special licensing and infrastructure are required in the form of a blast-proof, C1D1 storage facility.

It is common for scaling up considerations to include discussion of trading in a machine for another with a larger extraction vessel capacity, but this doesn’t apply to extraktLAB extractors. If you want to move from a single 140 model extractor to a facility that processes one ton of hemp per day, we recommend you buy 5 more units–all of which roll in on casters. Scaling up extraktLAB extractors is modular, easy, and maintains a small footprint.

Choice of Solvent

CO2 is an extremely effective and inexpensive solvent, and you’ll only spend about $1.32 to complete a full cycle of extraction. Ethanol extraction requires a large supply of food-grade ethanol – and again, stored on site in a blast-proof, C1D1 storage space. Running a full cycle of food-grade ethanol extraction will run you around $83.15.

Waste Removal

Both extraction methods may require proper disposal of raffinate and fats and waxes from the dewaxing process to stay compliant with state regulations. That said, you need to consider the additional (high) costs for ethanol recycling/waste removal.

While many new investors are drawn to the relatively low start-up costs of ethanol extraction, the costs of facilities, utilities, choice of solvent, and licensing all lead up to ethanol having significantly higher operating expenses. The increased cost of ethanol extraction is especially pronounced as you scale up.

How To Choose the Right CBD Extraction Equipment

In this section, we will discuss the important features and factors in choosing CBD extraction equipment for your hemp extraction business. The right CBD oil extraction equipment and setup are essential for optimizing CBD oil extraction.

The right CBD extraction equipment is critical for making the CBD oil extraction process quick, cost-efficient, and convenient.

Let us guide you on how to choose the right CBD extraction equipment.

When choosing the CBD Extraction equipment, you need to look for the following features:

- High yield and daily throughput

- Small occupied area

- Unlimited scalability

- GMP compliance support

- Ease of training for labor force

- Documented standard operating procedures (SOPs) for all processing steps

extraktLAB’s CBD extraction equipment has all of these features. Our line of supercritical CO2 extractors is the most advanced, efficient, and powerful in the hemp and botanical extraction industry today.

extraktLAB’s extractors have different capacities varying from 422 to 844 pounds per day depending on the extractor models e-140, and e-180.

These extractors are powerful, efficient, and practical systems for those producers who want the highest possible quality and productivity.

Our CBD oil extraction equipment is designed to provide the highest throughput yield in the shortest period of time. They satisfy all the traceability requirements for GMP compliance and have the highest quality and productivity in the extraction industry today.

extraktLAB’s supercritical CO2 extractor increases overall extraction yield thanks to its high efficiency automation and on-board methods. Other benefits include decreasing your yearly operating costs and options for scale-up opportunities.

Our customers produce award-winning CBD oils with extraktLAB’s supercritical CO2 extraction systems. extraktLAB’s extractors have gained the reputation of solid performers among processors and extraction experts.

Our equipment was designed by staff engineers who hold expertise and solid experience in building CBD oil extractors. Our systems efficiently and safely extract pure, high-quality essential CBD oils.

Once your extraction system is installed, you will receive proprietary training with one of our highly-qualified service engineers. We come to your facility and train you onsite, explaining and demonstrating how the machine works.

extraktLAB’s CBD Extraction Equipment Features, Cost and Scale Up Opportunities.

extraktLAB has everything you need to start and be successful in the extraction industry. Whether it’s equipment, information, certification or more, we are here to help. Starting out can be daunting, especially if you plan to scale up your business with no clear path, but our scale up systems are designed to help you succeed.

After years of research, we firmly believe that supercritical CO2 extraction is the best operationally, financially and environmentally and our equipment is designed for success in SCCO2 extraction.

We have a range of extractors that can handle anywhere from R&D levels of extract production up to 844 pounds of biomass processing power per day with a single extractor. All of our extraction solutions are fully scalable and can be tailored all the way up to a 5-ton per day extraction facility.

If you are planning to startup your first extraction facility, our full turnkey solution is designed to help you hit the ground running.

This solution covers the entire extraction process including bucking, decarboxylation, extraction, winterization and filtration, solvent removal, distillation, chromatography and product formulation.

We couple our equipment with onboard training and certifications if desired to ensure that your facility is up to code and optimized for full scale hemp extraction.

If you are interested in building a successful extraction business, or expanding your current operations to be more successful in the industry, we would be happy to work with you to find out where we can be of help.

Take a look at the rest of our website and you’ll find guides, courses, calculators and plenty of other resources that may help you get an idea of what you’ll need to get started, or what you could use to take your business to the next level. Then, contact one of our extraction experts to see where we can help in terms of equipment, services or training.

Questions? Contact extraktLAB Today

We’d love to help you pursue the exciting and most cost-effective opportunities available in cannabis extraction today! Please call us at 651-600-0036 or submit an online form for more information. Interested in learning how to master the extraction lab startup? Read more here! Check information here about how to make CBD distillate.

Frequently Asked Questions

Why should I choose extraktLAB equipment?

extraktLAB’s supercritical CO2 extractors are highly efficient and increase overall extraction yield. They are also capable of decreasing your yearly operating costs and leave scale up opportunities.

Does hemp biomass need to cure before extraction?

No, the material does not need to cure. Our methods complete the final drying step in a vacuum oven to bring the water content down from 10% to the 1% – 1.5% range for efficient CO2 extraction.

Can the drying process be accelerated using higher temps/lower humidity?

There are several drying methods used by growers to accelerate drying, but this is outside our scope of solutions. We recommend researching the agricultural methods to find what works best for you.

What are the typical conditions to dry hemp for extraction?

Harvest drying methods are outside the scope of our solutions; however, you want to dry the biomass to roughly 10% water content for quality storage to prevent mold or mildew.

When producing CBD from hemp, which part of the plant is typically used?

Typically flowers and leaves – no stems or stalks. Some producers will sort out the flowers and process them separately, but most processing includes the leaves and flowers.

Can ethanol become contaminated during ethanol extraction?

Yes, ethanol can become contaminated during ethanol extraction. It is important that you address the contamination with testing and reuse protocols. guidance for solvent reviews have been published by the FDA in 2010. Please refer to the many articles in this blog for more information on cross-contamination with extraction.

What is the electrical cost of ethanol extraction vs. CO2 extraction?

Processing a ton of hemp per day into extracts can be an energy-intensive process depending on how the hemp is extracted. The following table compares the energy expense for ethanol extraction versus the energy expense for CO2 extraction:

| Energy cost for Ethanol Extraction for 1 ton per day at 1 gallon ethanol per 1 lb of hemp | |

| 18711 | litres to cool from 25 to -20 |

| 16840 | litres to heat and evaporate after ethanol loss |

| 454 | kwhr to Cool from 25 to -20 |

| 481 | kwhr to heat to boiling point |

| 3105 | kwhr to evaporate |

| 4040 | kwhr total @ 100% Efficiency |

| 75% | Efficiency |

| 5387 | kwhr Total |

| $ 0.09 | per kwhr |

| $ 506.36 | per day |

| Energy cost for CO2 Extraction at 1 ton per day including winterization | |

| 636 | litres to cool from 25 to -20 |

| 636 | litres to heat and evaporate after ethanol loss |

| 15 | kwhr to Cool from 25 to -20 |

| 18 | kwhr to heat to boiling point |

| 117 | kwhr to evaporate |

| 151 | kwhr total @ 100% Efficiency |

| 75% | Efficiency |

| 201 | kwhr Total |

| $ 0.09 | per kwhr |

| $ 18.92 | per day for winterization |

| 43.20 | Kwhr per day for CO2 extractors |

| $ 3.88 | Per day for CO2 extractors |

Would you recommend ethanol extracted oils for Vape products?

Due to the risk of chemical contaminants that are found in 25 to 30% of ethanol extracted oils, we recommend that CO2 oils be used for Vapor Products.

Is it possible to make a solventless extract with CO2?

It is absolutely possible to make a solventless extract with CO2. Solventless extracts are typically made with subcritical CO2 extraction methods.

Does ethanol extraction have a greater throughput than CO2 extraction?

Hemp processing equipment can be scaled for 1 to 5 tons of extracted hemp per day. It’s generally not a fair comparison to compare the throughput on an instrument from two different companies. What is fair is to specify the throughput At the tonnage process per day and then look at the operating cost for that process. You can also look at the equipment and Facilities cost to accommodate that level of Production. after you have all of your costs accounted for including the hidden costs, then you can calculate the net present value for each investment.

What are the most common denaturants in ethanol?

Denatured ethanol is a mixture of denaturants and pure ethanol. Chemical companies add the denaturant to Pure ethanol so that they will not be consumed as a food.

Denatured recipes are published by the ttb that is administered by the National Bureau of Alcohol Tobacco and Firearms. There are many different recipes. one of the most common denaturants used in ethanol extraction is heptane. However there are other substances that may be used including acetone, isopropyl alcohol, methanol and other longer chain alcohols.

Is very limited data on the safety of heptane over the long term exposure. In fact the limit that the FDA has placed on the amount of heptane in a tincture for example was established in the 1990s on the basis of a single study published in 1981. That study the effect of heptane on Sprague dawley rats. That is why there are many disclaimers and the general guidance from the FDA is to limit the amount of solvent in any drug that is consumed.

Doesn’t ethanol extraction equipment remove all the ethanol from the biomass after extraction?

No. Approximately 5 to 10% of the ethanol is left in the biomass and is counted as a solvent loss. These solvent losses add up to operating costs. This is especially true if organic ethanol is used or food grade ethanol is utilized as the extraction solvent.

If you had an ethanol extraction facility, would you ever use CO2 just for stripping terpenes?

Ethanol extraction typically destroys the terpenes when the ethanol is removed from the extract or is distilled from the winterized oil. Many ethanol extractors are seeking a way to preserve the terpene profile of the plant in the output oil. To this end people have tried techniques such as Steam distillation, CO2 stripping, and vacuum distillation.

Certainly, CO2 can be used to strip terpenes from Hemp biomass Prior to ethanol extraction. However, vacuum distillation is by far the most gentle and effective way to harvest the terpene profile prior to ethanol extraction.

How do I model and compare the financial return of ethanol extraction vs CO2 extraction?

There are many inputs that need to be defined when creating a financial model comparing two different extraction methods. The first decision to be made is to decide what the financial metric will be used to make a decision on the superiority of one method over the other.

In this case, we recommend the use of the Net Present Value as the way to model the return of each extraction technique because it accounts for the cash flow associated with the operation. Many ethanol extraction companies try to make the argument that ethanol extraction is lower cost because the equipment cost is less. However, the equipment cost will have very little impact on the overall profitability of the operation at the same throughput.

The best way to compare the two techniques is to fix the throughput so that an apples-to-apples comparison can be made. Comparisons such are payback time and return on investment can mislead someone into making a bad investment decision.

So if we fix the throughput at one ton per day the cost of the hemp is equal between the techniques and operating cost variance is the only contributing factor.

Here are the twelve key questions that need to be defined in order to do a comparison:

- What is the direct labor to process?

- What is the energy to process?

- What are the solvent losses?

- What are the direct material startup costs including solvent startup costs?

- What are the cannabinoid recovery rates?

- How much solvent do I use, reuse, and when do I need to replace the solvent with fresh solvent? and at what interval?

- What is the insurance cost for each option?

- What is the cost of hazardous waste disposal?

- What is the cost of solvent removal?

- What is the cost of reuse of the solvent?

- What is the cost of HAP emissions?

- What is the depreciation for each option including building costs for H2 vs F2 occupancy?

Once these questions are answered you will be able to build a pro forma income statement.

Revenue

- Standard labor

- Standard materials

- Overhead

Gross margin

- SGA

- R&D

Net Margin

You can then hold SG&A and R&D constant for both techniques and account for the difference in depreciation to get to a net margin number.

A cash flow statement can then be generated from net margin. One thing to note is that depreciation must be added back to net margin as it is a non-cash expense on the income statement.

Cash flows are then added up for 5 consecutive periods (years) including the initial outlay of cash for startup working capital. Those cash flows are then discounted at a discount rate (Weighted average cost of capital estimate at 13-17%).

If you do this analysis, you will find that CO2 extraction will absolutely crush ethanol extraction in terms of net present value.

Does it cost less to process hemp with Co2 compared with Ethanol?

Yes.

In fact the operating cost for CO2 extraction is dramatically less than the operating costs associated with ethanol.

Extraction with Ethanol is a process that is typically run at low temperatures. First the ethanol is cooled to below -20oC before it is introduced to the hemp. Cooling the ethanol reduces the amount of extracted chlorophyll and waxes. If you account for the energy required to chill the ethanol down to those low temperatures and then also evaporate after use, the energy bill for extracting ethanol is approximately 3-6x the cost of extracting with CO2. However, the energy cost is really not the key driver in the overall operating costs.

Ethanol extraction requires a significant amount of ethanol to be used per pound of hemp. In fact, about 1 to 1.5 gallons of ethanol must be used per pound of dry hemp in order to extract. Hemp is a very absorbent biomass material and the ethanol must fully saturate the hemp plant before any extraction can take place. For this reason a large volume of ethanol is needed to extract cbd from hemp.

The key cost driver or ethanol extraction is recovery of that solvent from the biomass. Even though many ethanol extraction equipment companies provide centrifuges and or presses to eliminate the amount of ethanol left over in the biomass, The best equipment will provide only a 90 to 95% recovery of the ethanol. This 5 to 10% loss in ethanol is a huge cost driver for extracting ethanol.

For example, suppose you wanted to process 1000 lb of hemp. You would need 1000 gallons of ethanol to start out at a cost of $16-33 per gallon for food grade ethanol for a total cost of $16,000 to $33,000. If you recovered 90% of the ethanol the ethanol loss would be $1,600 – $3,300 per 1000 lbs. Furthermore if you process 1000 pounds per day, this would be your daily loss.

In contrast, you will lose the equivalent of about $70 per day for CO2 extractions for the exact same process.

Besides energy and solvent usage, there are many other hidden costs related to extraction with ethanol including solvent reuse costs, insurance cost, increased facilities cost, and testing costs.

Is CO2 cheaper than ethanol?

Yes.

A pound of food grade ethanol when purchased in bulk is $4.71/lb at current price.

A pound of food grade CO2 when purchased in bulk is about $0.04/lb at current price.

What’s the purity of the CO2 used in CO2 extraction?

There are many grades of CO2 including industrial and food grade and medical grade. We typically use food grade but medical grade is also highly desirable. the specifications for each of these grades are published by the Compressed Gas Association or by your gas supplier.